BHP eliminates intermediate casing string in Permian pilot

BHP Billiton Petroleum eliminated an intermediate casing string in a Permian basin pilot by switching to an oil-based mud (OBM) from a water-based mud.

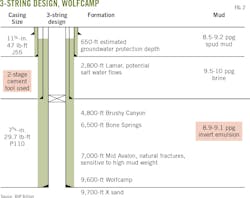

Legacy casing design involved four strings, including two intermediate casing strings in the vertical part of the well.

The switch to OBM enabled use of only one intermediate casing string, which saved casing and service costs and reduced rig time.

Luke Bibler, BHP drilling engineer, told OGJ, "Invert emulsion fluids are a viable option for certain Permian basin wells."

Good offset control and knowledge of area injection wells is key, he said. If water flow from injection wells is higher than 10 bbl/hr, BHP's cost to maintain the drilling fluid becomes too high.

A three-well pilot in July 2015 provided BHP with $114,000 in savings on State Pish lease in Reeves County, Tex. The lease is near Orla, about 40 miles north of Pecos, Tex.

When BHP's Permian basin program reaches development mode, OBM likely will be deployed where practical, Bibler said."In the current oil-price environment, the cost of tangibles such as casing, casing accessories, and services has depressed significantly," Bibler said. "This has decreased the [proportion of] savings obtained by eliminating the 95⁄8-in. casing string."

BHP has one drilling rig working in Permian's Wolfcamp shale, which offers a variety of geological zones.Horizontal drilling and hydraulic fracturing have made Wolfcamp's development feasible.

BHP has increased its Permian liquids production while slowing development activity in the Delaware basin.Andrew Mackenzie, BHP Billiton Ltd. chief executive officer, said BHP has responded to low oil prices by reducing onshore US rigs. "We are well positioned to bring on shale volumes as markets tighten," MacKenzie told analysts during a June earnings call.

Eagle Ford knowledge swap

Eliminating an intermediate string in Permian legacy casing design stemmed from techniques BHP engineers first developed in the South Texas Eagle Ford shale.

BHP is applying knowledge gained in Eagle Ford to build operational and technical expertise of the Permian during the oil price slump. Its Permian production as of mid-2015 was 30,000 boe/d, a company report showed.

Recent progress in BHP's Wolfcamp program includes better well placement, extended lateral lengths, and optimized completions, leading to increased recovery and predictable well performance.

Salt zones and nearby injection wells required BHP to use a higher mud weight while drilling shallow, first-intermediate sections. "Injection wells communicate with our wells, causing water flows upwards of 300 b/hr depending on proximity and drilling mud weight," Bibler said. "In the deeper, second-intermediate section, there are weak zones (Avalon) that require a lighter mud weight to drill and then set casing."

BHP needed an OBM for drilling through salt zones without washing out of the hole and gaining weight. The mud also needed the ability to absorb fluid associated with certain injection wells. The goal was to allow drilling fluid to maintain a light weight for drilling the weak, deeper zones without a requirement to case off the shallower sections.

Cement costs increased using the OBM. A two-stage cement tool was needed to lift cement to the surface in the pilot. OBM cuttings are required to be hauled off the drillsite compared disposal in an onsite reserve pit, which added cost. OBM also costs more than water-based mud.

The wellhead was designed to house four casing strings. A packoff was needed to eliminate the 95⁄8-in. string.

About the Author

Paula Dittrick

Senior Staff Writer

Paula Dittrick has covered oil and gas from Houston for more than 20 years. Starting in May 2007, she developed a health, safety, and environment beat for Oil & Gas Journal. Dittrick is familiar with the industry’s financial aspects. She also monitors issues associated with carbon sequestration and renewable energy.

Dittrick joined OGJ in February 2001. Previously, she worked for Dow Jones and United Press International. She began writing about oil and gas as UPI’s West Texas bureau chief during the 1980s. She earned a Bachelor’s of Science degree in journalism from the University of Nebraska in 1974.