Study questions specified hydrotest hold time's value

Harvey Haines

Kiefner & Associates Inc.

Vienna, Va.

John Kiefner

Michael Rosenfeld

Kiefner & Associates Inc.

Worthington, Ohio

The value of a particular hold time during a hydrotest cannot be determined in terms of pipeline integrity because the consequences of holding cannot be measured, making any specified hold time of the maximum test pressure arbitrary.

Verifying the safe pressure-containing capability of a pipeline at its maximum allowable operating pressure (MAOP) requires a pressure test of the pipeline. This pressure test should exceed the MAOP by a safety margin sufficient to validate the stability of remaining anomalies. Regulations specify the duration for which pressure must be maintained, commonly called the hold time.

The hold time is intended to allow sufficient certainty that there are no leaks in the pipeline. Starting in 1970, Federal Regulations required a hold time of 8 hr. Before this, when hold times were often less than 8 hr, the use of a shorter hold time introduced no increased risk of a rupture. Although a shorter hold time may increase the risk of a leak being overlooked during testing, any subsequent leak of significant volume should be discovered by required operator leak surveys, or by customers who would smell the odorant added to the natural gas stream specifically for the purpose of detecting leaks.

Pressure tests conducted after building the pipeline ensure no inadvertent manufacturing or construction defects are present that could affect the safe operation of the pipeline, having escaped detection before the pipeline was placed in service. Test effectiveness derives from the hoop stress imposed in the pipe wall, irrespective of the testing fluid or medium, meaning water, air, or natural gas can be used to test the pipeline for such defects. Though the consequences of a rupture during testing could vary greatly with the type of fluid used in the test, the test fluid used has no impact on test effectiveness.

Background

In response to the natural gas pipeline rupture and explosion in San Bruno, Calif., which killed eight people, the National Transportation Safety Board (NTSB) issued safety recommendations urging Pacific Gas & Electric Co. (PG&E) and the California Public Utilities Commission (CPUC) to ensure all Class 3 and Class 4 locations and all Class 1 and Class 2 high-consequence areas (HCAs) have had a valid MAOP established through previous hydrotesting (OGJ Online, Jan. 6, 2011).

The CPUC directed all California utilities, not just PG&E, to review all their historical records to determine if valid pressure tests had been conducted on their pipelines. Utilities throughout the country were also urged by regulators to investigate their historical pressure test records.

Before 1970, when Federal pipeline safety regulations went into effect, an 8-hr hold time was not required and not necessarily observed by all pipeline operators. California's General Order 112 specified a 1-hr hold time when it was established in 1961, but no hold time was specified in the ASA-ASME codes as far back as 1952. This article will address whether or not the 8-hr hold time is needed to verify MAOP on pipelines tested before 1970, and if a hold time of 1 hr is even needed in pipelines tested in California before 1961.

Figs. 1-2 show pressure records from two different hydrotests by two different operators. Fig. 1 is from a test conducted November 1962 on 9,055 ft of 12-in. OD, 0.219-in. WT, X42 pipe. The test used water as the pressure medium and the chart shows the test pressure of 1,400 psi held from 4:05 p.m. to 7:20 p.m., or 3 hr 15 min.

Fig. 2 shows a pressure test between 1,550 and 1,575 psi held from 11 a.m. to 3:15 p.m., or 4 hr 15 min. The pipe is a 38-ft tie-in section, consisting of a 22-in. OD, 0.344-in. WT, X52 pipe and an 8-in. OD, 0.322-in. WT, X42 pipe. Short tie-in sections do not require a long hold time to find leaks as they will become apparent more quickly.

Hold time vs. safety

Understanding hold time requires understanding the regions of crack growth. Under an increasing stress level, or at a sustained stress level very close to the failure point, crack growth proceeds in a stable manner until the crack grows large enough to become unstable and proceeds to failure.1

The vast majority of pipelines consist of line pipe steels with an operating temperature above its fracture initiation transition temperature. At temperatures above the fracture initiation transition temperature, line pipe steel behaves in a ductile manner.

The authors of the referenced study describe ductile behavior in terms of irreversible strain, or creep-like behavior in the presence of a crack-like defect. In creep-like behavior, defects exhibit physical extension at stress levels below their failure stress levels. Defect extension occurs when the ultimate strain capacity of the material in the vicinity of the defect is exhausted. Ductile failure is time-dependent, with crack growth continuing, albeit slowly.

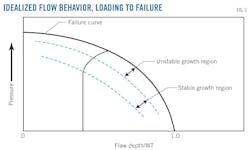

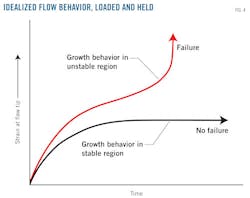

Depending on how close applied stress is to the failure stress of the defect, this crack creep-like behavior may continue until a sudden unstable extension of the defect occurs, or it may decrease and cease altogether (Fig. 3).

As a pipe defect is stressed though increased internal pressure, it begins to change depth after reaching a minimum pressure. Fig. 3 shows this where the vertical line of the graph starts to curve to the right. With further increases in pressure the crack continues to elongate until a critical pressure level is reached, at which time the defect will fail.

The initial portion of the loading cycle, where growth is so small it is difficult to measure, is essentially a region of no growth, and is termed the stable growth region in Fig. 3. If the loading of the defect in this region were stopped and held constant, the defect would continue to grow slowly for some period of time and then stabilize.

If, however, the defect is loaded to a higher stress level into the unstable growth region (Fig. 3) and if the loading stops in this region, the defect will continue to grow until failure occurs, even without a further increase in load. Fig. 4 shows the strain vs. time pattern in these two regions.

The regions where stable or unstable crack growth can occur under static stress are often encountered during the hold time of a pressure test. Unstable crack growth will eventually lead to failure if the load is held long enough, while stable crack growth will stop.

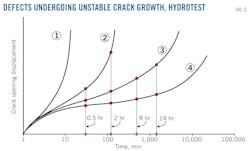

Fig. 5 shows four hypothetical cracks undergoing unstable growth. Each of the four defects is slightly less severe than the first. In a test to a given target test pressure all are severe enough to enter the unstable crack growth region and grow to failure at the target test pressure if the pressure is held long enough.

The curves represent the crack-opening displacement over time during the test for each crack. As the curve turns upward the crack opening becomes infinite, representing failure. Times to failure are about 10 min, 2.5 hr, 5 days, and 1 month for Defects 1, 2, 3, and 4, respectively.

A flaw is unknown during a hydrotest until a defect fails, which prevents knowing the status of the four defects until they fail. The most severe defect, Defect 1, is going to fail in 10 min irrespective of which time is chosen. With a 30-min hold, three defects survive. With a 2-hr hold, three defects still survive, but all are in worse shape than if the hold had been a half-hour. The 8-hr hold gets rid of Defect 2, but leaves Defect 3 worse off than Defect 2 after a 30-min hold.

In this example the 30-min test gives the best outcome because the largest surviving crack (Defect 2) has a smaller crack opening displacement than the largest remaining crack opening displacement at the end of the three longer hold times. The 2-hr hold gives the worst outcome. And since no crack failed between the 8- and 24-hr hold times, both remaining cracks have grown and are larger after a 24-hr hold time.

None of the surviving defects would pose a short-term threat to the integrity of the pipeline at an MAOP a reasonable margin below test pressures. The amount of flaw extension during testing is primarily a concern where a mechanism for the flaws to enlarge at service stress levels exists, such as the effects of large operational pressure cycles or large pressure excursions.

The example is hypothetical and is not meant to portray everything happening in every hydrotest, but it does illustrate that longer test times may not be beneficial and it is impossible to choose the best hold time because the pipeline operator has no way of knowing what defects, if any, exist or how close they are to failure if they do not fail during the test.

An operator, therefore, cannot choose the best hold time for the purpose of demonstrating pipeline integrity. The value of a particular hold time cannot be ascertained in terms of pipeline integrity because the consequences of holding cannot be measured, making any specified duration of the maximum test pressure arbitrary.

The effect of hold time at maximum test pressure is to cause defects to grow and perhaps cause those defects to fail that would otherwise have required higher pressures to fail under straight pressurization.2 Holding at the maximum test pressure level causes defects that grow substantially to fail and also causes a portion of the remaining family of defects to extend, creating one of the following situations:

• At the end of an arbitrary hold period in which no failures occur, a portion of the remaining defects has grown. The hold period was thus of no value since it only caused the growth of defects without additional failures.

• At the end of an arbitrary hold period in which one or more failures occur, the cycles of pressure needed to reestablish hold following each failure cause any remaining defects to grow and increases the probability of a subsequent failure.

• At the end of a hold period terminated by a test failure, there is just as likely to be a defect on the verge of failure as there would have been if the test had been terminated with a shorter hold time.

Finding leaks

Small defects requiring detection may exist in the pipe. If these defects are small enough they will not lead to an immediate drop in hydrostatic pressure during a pressure test with water, but will lead to a small amount of fluid leaking through the defect that will cause a gradual drop in test pressure.

It is often difficult to distinguish the difference between variations in pressure caused by thermal fluctuations of the fluid in the pipeline and gradual loss in test pressure due to small leaks. The large volume of test fluid in a pipeline makes it advantageous to hold the pressure long enough to reach thermal equilibrium, so thermal effects no longer mask pressure loss due to small leaks. This reasoning established the 8-hr hold time in the CFR 192 Part J test.

Holding for the purpose of detecting leaks does not have to be done at the maximum test pressure to be effective. It should, however, occur at an applied pressure level above the operating pressure to improve detection of leaks only open at high pressure near or above MAOP.

Part J stipulates hold at 1.25 times MAOP for Class 2 locations. The stipulation provides the reasoning for a spike test to remove defects at multipliers of 1.39, 1.5, or higher times the MAOP, followed by returning the pressure to 1.25 times MAOP to perform a leak test, meeting the requirements in CFR 192, and finding leaks open at high pressure.

Shorter hold times are adequate for aboveground pipe, because small leaks such as may occur at flanged connections can be identified visually. Even if makeup water needs to be added during the test to maintain pressure, the strength of the pipe is proven. The leaking gasket can be changed after the test and checked for leaks as it is brought up to operating pressure.

Pressure tests performed before 1970 without an 8-hr hold test should still be considered a valid pressure test to prove the pressure carrying capability of the pipeline. The lack of an 8-hr leak test is immaterial, because leaks would have been found over the subsequent life of the pipeline by the operator through surveys, or by customers by the odorant in the gas.

Test medium

Although it is most common to use water as the test medium for modern pressure tests, other fluids are acceptable as test media for proving the pressure carrying capability of the pipeline. Both gaseous and liquid media have advantages, but the primary advantage of using water is test safety.

If a pipeline ruptures with water, the pressure is released almost immediately with only a relatively small amount of water being released at the rupture location. If a gas is used, however, especially in an older, lower-toughness material, the speed of the fracture can outrun the decompression of the gas in the pipeline, causing ruptures of hundreds to thousands of feet.

These propagating fractures can run for miles if the fracture propagation transition temperature is above the test temperature or the upper shelf fracture toughness is not high enough. The longest such rupture recorded during a gas test was more than 8 miles. If air or gas was successfully used in a past test, there is every reason to take the maximum pressure recorded during the test the valid proof, just as if water had been used.

Other advantages and disadvantages of various pressure test media include:

• Natural gas is already in the pipeline and the medium will therefore mimic the pressure profile of the pipeline in actual service. The density of the fluid will cause pressure to change with elevation, and using the same medium as will be used in service will exactly mimic the pressure variations occurring in service. This characteristic is especially advantageous in mountainous terrain, where elevation changes are extreme.

Disadvantages are obvious. If the pipeline ruptures and the gas ignites a large explosion and fire will result, usually considered an unacceptable safety hazard except in the most rural settings.

• Air or nitrogen is sometimes used in place of natural gas in mountainous terrains because it has a density very close to that of natural gas or methane but lacks the fire hazard. The chance of a running propagating fracture, however, still exists.

• Water is preferred for safety reasons, but can be difficult to dispose of for environmental reasons. Using water in a pipeline requires it be treated as a hazardous material, because it will absorb any hazardous chemical in the pipeline. Water not removed after a hydrotest and left in the pipeline can cause future integrity problems through internal corrosion. If the test water comes from a natural source such as a river or lake and has not been treated, any bacteria introduced in the pipeline can cause microbiologically induced corrosion (MIC) which can aggressively corrode pipeline steel. Residual moisture may also be a nuisance to gas users.

The disadvantage of water over any gas from a test perspective is its higher density. Meeting the minimum test pressure requirement at the highest elevation of the tested line segment requires all points at lower elevations to experience a higher test pressure due to the static head effect. Where large differences in elevation exist, the pipeline must be tested in short segments to avoid unacceptably high test pressures at lower elevations, increasing the length of time a pipeline may be out of service to complete all tests.

References

1. Kiefner, J.F., Maxey, W.A., Eiber, R.J., "A Study of the Causes of Failures of Defects that Have Survived a Prior Hydrostatic Test," PRC/AGA NG-18 Report No. 111, Nov. 3, 1980.

2. Kiefner, J.F., and Maxey, W.A., "The Benefits and Limitations of Hydrostatic Testing," API Pipeline Conference, San Antonio, Apr. 18-19, 2001.

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com