Hydrogen infrastructure expansion requires realistic framework

Mark W. Shuster

Shuvajit Bhattacharya

Ian J. Duncan

Peter Eichhubl

Seyyed A. Hosseini

Farzam Javadpour

Jay P. Kipper

Ning Lin

Jean-Philippe Nicot

Bo Ren

Bureau of Economic Geology

Austin, Tex.

With expected improvements in hydrogen generation technologies (most notably electrolysis) and reduction in costs, the supply of hydrogen will grow. Modeling and assessing supply- and demand–driven market scenarios will provide the framework through which to better plan for realistic infrastructure and storage requirements.

Hydrogen (H2) offers the potential for a transportable, storable fuel for a low-carbon economy. Hydrogen can be generated through electrolysis using solar, wind, or nuclear power sources without greenhouse gas emissions, or from hydrocarbons such as natural gas using processes like steam methane reforming.

Because carbon dioxide is released when hydrogen is generated from hydrocarbons, carbon capture and storage would be required to reduce greenhouse gas emissions. Current world hydrogen production is 70 million tonnes/year: 76% from natural gas, 22% from coal gasification, and 2% from electrolysis. The US Department of Energy (DOE) estimates that 1% of 2020 US hydrogen production was obtained by electrolysis and 99% from natural gas through steam reforming of methane (95%) and coal gasification (4%).

Although electrolysis-generated hydrogen is a small percentage of the current total, expected cost reductions through technological developments pave a path to increased electrolysis-generated hydrogen over the next decade. Regardless of the source of hydrogen, its envisioned use as an energy carrier of urban, regional, or national scale will require development of a robust supply network integrating storage, transportation, and distribution infrastructure.

Today, hydrogen is used primarily as a feedstock for petrochemical manufacturing and processing. Hydrogen is an effective energy carrier that can be stored indefinitely for long-term use. Hydrogen can be transported as a gas, as a supercooled liquid or, with additional processing, converted to compounds (e.g., ammonia or methanol) or absorbed onto solids.

Hydrogen as a gas offers the simplest energy carrier and storage option. It can be used directly for energy generation through combustion or fuel cells, or as feedstock for industrial manufacturing of hydrogen-based solid and liquid compounds. Because of hydrogen’s relatively low energy density by volume, however (about one-third of the energy per unit volume of natural gas), hydrogen storage and transportation are critical for large-scale utilization. In the US, an extensive natural gas pipeline network provides an excellent starting point for hydrogen transportation and distribution. Large-scale storage will need to be developed for hydrogen to allow for supply beyond current industrial usage.

Energy deployment, storage

Energy deployment and storage, and the cost thereof, is one of the major issues facing the transition from fossil fuel-based to renewable energy sources. Depending on geography, solar and wind provide cost-effective means of generating electricity. But electricity generation from solar or wind is variable, reflecting daily and seasonal cycles. Consequently, energy storage or backup energy generation is required to modulate variations in demand and supply.

Electrochemical battery sites have been built to provide backup for short-term fluctuations. But the energy capacity of the largest currently under construction, at Moss Landing, Calif., is 1.2 gigawatt-hours (Gw-hr) with a discharge duration of 4 hr. For comparison, what would be considered a small underground natural gas (methane) storage site with capacity of 1 bcf has an energy equivalent capacity of 300 Gw-hr.

At about one-third the energy content of methane, a 1-bcf hydrogen storage site would have an energy storage capacity of about 100 Gw-hr. Importantly, hydrogen gas can be stored indefinitely as compressed gas, allowing for weekly, monthly, and seasonal storage and backup as well as providing strategic energy reserves for increased energy resilience and security. Therefore, even as a low energy-density gas, hydrogen affords the potential for indefinite-duration energy storage and energy supply at scale when combined with large geological storage. Geological storage as part of an integrated hydrogen pipeline and transportation infrastructure connecting supply to end users will be necessary to develop a lower greenhouse gas emissions economy including hydrogen.

US gas systems

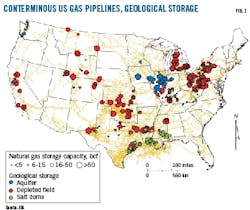

Before discussing hydrogen storage and infrastructure, it is important to summarize the current natural gas system in the US to reference the scale of existing gas supply and consumption. The US consumed 31.1 tcf of natural gas in 2019. Natural gas consumption is seasonal, with maximum use during winter months and decline during summer months, reflecting use for heating. The 2019 consumption rate averaged 85 bcfd. Natural gas infrastructure consists of roughly 3 million miles of pipeline and 4.25 tcf of storage (Fig. 1).

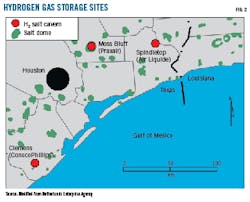

According to the US Department of Energy (DOE) Office of Energy and Renewable Efficiency, about 1,600 miles of hydrogen pipeline exist in the US. Currently, the country has three subsurface hydrogen gas storage sites: Clemens Dome (ConocoPhillips), Moss Bluff (Linde PLC), and Spindletop (Air Liquide SA), all used for petrochemical processing (Fig. 2). All three are in man-made, salt (halite) dissolution caverns in salt domes in southeastern Texas. Based on data compiled by the Netherlands Enterprise Agency, the combined H2 capacity of these three sites is 14,320 tons of H2, with a net gas-volume storage capacity of 5–6 bcf at rated storage pressures of 70–137 bar (1,000–2,000 psi) at Clemens Dome, 55–152 bar (800–2,200 psi) at Moss Bluff, and 68–202 bar (990–3,000 psi) at Spindletop.

Hydrogen gas storage

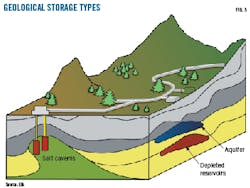

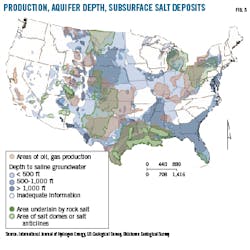

Based on multiple decades of experience in natural gas storage in the US, geological storage in salt (dissolution) caverns, depleted oil and gas fields, and saline aquifers affords the potential for large-volume storage capacity of hydrogen gas (Fig. 3). Salt caverns present the advantage of allowing fast injection and withdrawal rates and high sealing capacity. The salt caverns are created by brine mining, where low-salinity water is pumped into the salt through a wellbore and the brine is pumped out, leading to the creation of a chamber.

From the Air Liquide permit application, the top of an individual cavern is at about 3,700 ft, the bottom at 5,400-ft depth, and approximate diameter is 250 ft. For a cavern like this, with a 1,700-ft vertical extent, a thick salt body (salt dome) is a prerequisite.

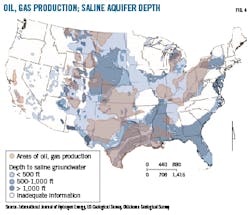

Porous media, specifically sandstone and carbonate reservoirs, offer much larger volume capacity opportunities for gas storage with broad geographic coverage (Fig. 4) and are used extensively for natural gas storage. They fall into two broad categories:

- Depleted oil and gas reservoirs, with proven storage volume, reservoir properties, and top seal capacity.

- Saline aquifers, with abundant potential locations but unproven gas trapping and recovery characteristics.

Although both depleted fields and saline aquifers are used for natural gas storage, they have not been tested for hydrogen gas storage. The depleted fields and aquifers would need to be evaluated for suitability for hydrogen storage based on their depth, porosity, permeability, internal homogeneity, and the integrity of their top seals. Ideal reservoirs would be internally homogenous and exhibit high porosity and permeability and an overlying top seal with sufficient sealing capacity. Depleted oil and gas reservoirs, particularly gas reservoirs, may also be advantaged by having basic infrastructure (for example, roads, production pads, pipelines, and wells) that may be wholly or partially repurposed for hydrogen storage and production purposes, although abandoned legacy wells may provide potential leakage pathways.

The combination of storage in salt domes, depleted fields, and saline aquifers would provide large-scale storage options for hydrogen across much of the US except parts of the northwest, northern Midwest, and Appalachian regions (Fig. 5).

Synergies, differences with CCS

Many coal-fired and gas-fired assets are positioned above suitable geology, for example, those along the Texas and Louisiana Gulf Coast, where there is also a demand for chemical and petrochemical use of hydrogen. The presence of multiple subsurface storage targets also provides CO2 reservoirs or even, as is the case in the Gulf Coast, use of CO2 for enhanced oil recovery (EOR).

Carbon dioxide is produced in the most common mode of hydrogen generation from methane. Synergies in co-locating geological H2 storage with nearby CO2 storage sites could reduce costs through development of integrated systems and could also provide H2 and CO2 for generation of synthetic fuels. Other technological fields such as helium storage, natural gas storage, acid gas disposal, aquifer storage and recovery, and nuclear waste disposal in clays share some characteristics with H2 storage. They can provide useful insights and accelerate the development of H2 storage technology.

Hydrogen storage has specificities not shared with CO2 storage, such as the cyclicity of hydrogen operations as opposed to permanent disposal for CO2. Hydrogen storage also has a depth trade-off missing from CO2. Storage needs to be deep enough for adequate capacity and reduced leakage risk but not so deep as to hinder operations and increase compression costs. CO2 storage, by contrast, increases capacity and virtually eliminates leakage risks through geological features.

The National Energy Technology Laboratory has estimated the capacity of CO2 sites in oil and gas reservoirs, saline formations, and unminable coal deposits for the US. Although the total capacity is high (mean case of 8.6 trillion tons of CO2 capacity), based on the first-order pressure and temperature constraints, only about 2% of the estimated capacity would be suitable for hydrogen gas storage.

More fundamentally, there are large differences in behavior between hydrogen gas and supercritical CO2. These differences impact preferred reservoir geometry. For example, a narrow reservoir with a long vertical section would limit fingering of the injected hydrogen and potential subsequent material loss, but it would also generate high pressure on the reservoir ceiling. It follows that, although a rich literature and numerous case studies on natural gas and CO2 storage in porous media reservoirs exist, hydrogen properties require explicit attention.

For example, recent studies on gas transport in nanoporous structures such as shale gas reservoirs have revealed that some classical models for gas migration may not be fully suitable to estimate material loss through fine-grained porous media. Small projects and previously operational sites (using a blend of methane and hydrogen) have shown that storage in porous reservoirs is viable, but the approach has not been fully assessed. The efforts required to study such reservoirs in the context of hydrogen storage are dwarfed by their benefits.

Hydrogen geological storage

The relative lack of scientific and technical knowledge on hydrogen behavior in the subsurface is a barrier that can be resolved with further research. Effective implementation of hydrogen as an energy carrier requires practical, economical, and verifiably secure storage technologies that, in combination, provide the needed storage volume, proximity to source and end-user, and rates of storage and retrieval to respond to short- and long-term variations in demand and supply.

Subsurface storage in caverns or porous formations provides a large storage capacity with a smaller surface footprint and less environmental costs than surface-based energy storage options of comparable capacity, such as compressed surface tanks or electrochemical batteries. Gases can safely be stored in the subsurface, as demonstrated by the existence of numerous geological deposits of natural gas and CO2. General knowledge accumulated by studying these gas reservoirs can be transferred to understanding the behavior of a reservoir in which hydrogen is a major or the sole component of the gas phase.

Hydrogen gas is highly diffusive; fortunately, its solubility is low, on the order of methane. Hence, diffusion losses through a thick seal, which would have low concentration gradients, are expected to be minor. Compared with natural gas, a propensity of hydrogen gas to breach the seal is higher due to the lower hydrogen density leading to higher hydrogen pressure for the same gas-column height. But interfacial tension of the water–hydrogen system is relatively higher, resulting in a lower risk for capillary leakage.

Formal approaches to evaluate these effects exist in the oil and gas industry but need to be adapted to a hydrogen system. Dissolved gases are common in the subsurface (CH4, CO2, N2, O2, Ar, and sometimes H2S), and they tend to partition into the gas phase from the aqueous phase. It is understood that these dissolved gases will progressively attenuate and disappear from the production stream as the residual water releases its dissolved gases in successive cycles. But in the case of a depleted gas field, methane might be added to the producing stream for many cycles. In a depleted oil field, light hydrocarbons (C1–C5 and aromatics) might also be produced for many cycles. Besides, hydrogen can be consumed by microbes, which are always present in the subsurface and as a result add H2S to the producing stream as sulfate is consumed.

In some other cases (Archaea) microbes can produce methane from hydrogen. A minor abiotic reaction can also produce H2S when pyrite is exposed to hydrogen. Research needs include laboratory and field tests of hydrogen-hydrocarbon-brine-mineral interactions over characteristic residence times of stored hydrogen in reservoirs with varying production and injection history.

Porous-media subsurface storage offers both long-term and large-scale capacity. The concept has been used for subsurface storage of other gases (natural gas, CO2, helium, compressed air), and many aspects of the technology can be transferred to hydrogen storage with limited adjustments. Subsurface storage also offers flexibility in terms of the exact composition of the stored gas.

A blend of natural gas and hydrogen may have less impact on the wellbore system and surface infrastructure and can be optimized easily without modifying the technology fundamentally. The subsurface component of the technology can be finely understood and ready for at-scale use after developing operational experience from pilot tests, for example on the Gulf Coast, with utilities and industry nearby, and then applied throughout the country.

We envision two major focus areas of research to support the development of hydrogen storage at scale. The first is understanding hydrogen storage in porous-media reservoirs, especially sandstone and carbonate reservoirs in depleted oil and gas fields and saline aquifers. The second is to define criteria to systematically categorize and evaluate geological storage sites for hydrogen storage across the US.

Storage in porous media

Understanding hydrogen storage in porous media requires determining hydrogen’s interaction with reservoir rock and fluids, encompassing factors such as:

- Mobilization of dissolved gases.

- Generation of gas impurities through microbial activity.

- Flow behavior and interaction with in situ fluids.

- Modification of flow properties following reactions with minerals.

The proper way to evaluate top seal and fault seal capacity for H2 reservoirs must also be determined, including evaluation of approaches developed for oil and gas reservoirs, such as fairways of suitable storage reservoirs at different pressures and mapping stacked reservoirs. The geomechanical effects of rapid production and injection cycling also need to understood, as do any geomechanical or reservoir engineering issues that need to be mitigated for commercial-scale development.

Conducting field tests for hydrogen storage in depleted fields and saline aquifers will provide data to inform large-scale development of hydrogen storage and better define selection criteria for potential storage sites. Criteria for reservoir evaluation and categorization include:

- Depth, pressure.

- Porosity, pore geometry.

- Permeability.

- Reservoir size, configuration.

- Reservoir heterogeneities.

- Reservoir mineralogy.

- Seal quality, trap effectiveness.

- Location, infrastructure.

- In situ fluid compositions.

In situ hydrogen generation

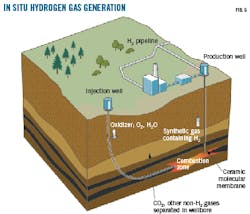

Hydrogen can be generated from in situ combustions (ISC) of hydrocarbons and underground coal gasification (UCG) under controlled conditions. Pilot ISC at Cold Lake field in Alberta, Canada, and multiple UCG projects in the 1970s and 80s generated hydrogen in situ and produced it to the surface. But investigation into hydrogen generation via in situ means did not receive much attention in the US.

Continued research and applications of ISC for EOR has demonstrated the viability of this process for increased recovery in different reservoir types. An opportunity exists to investigate the potential of ISC for the primary purpose of hydrogen generation in porous media. The benefit of generating hydrogen from the subsurface is that it would provide a direct hydrogen source utilizing thermal energy from the combustion of hydrocarbons in place. If hydrogen can be produced at the wellhead from ISC, CO2 and other emissions can be separated and reinjected into the subsurface. Additionally, new developments in selective filtering membrane technology can be adapted for use downhole, opening the door for systems to allow for hydrogen production from the reservoir while retaining some or all cogenerated CO2 and other emissions in the reservoir.

A new area of research has emerged for investigation of ISC for hydrogen production. The research starts with reservoir and ISC modeling coupled with laboratory experiments to understand the reactions in hydrocarbon-filled porous media under different conditions. From that work, reservoir types and fields that would be suitable for designing and conducting pilot tests would be identified, leading to potential development. At the same time, work could be done by materials scientists and engineers to adapt and test ceramic molecular membranes for downhole hydrogen separation.

Key research questions include:

- What is the optimal temperature for gasification by fire flooding, and how can the temperature field be manipulated?

- What type of hydrocarbon reservoirs are most prospective for hydrogen production?

- What depths and pressures would be viable?

- What hydrocarbon types and saturations would be preferable?

- What reservoir attributes, including geometry, thickness, connectivity, porosity, and permeability, would be conducive for effective in situ combustion?

- How does the phase chemistry of the reservoir change as the oxidation front evolves?

- How can catalysts and membranes be deployed to maximize hydrogen production?

- What injection and production schemes should be considered?

- What well geometries will be most efficient and cost effective?

At-scale hydrogen storage

DOE has envisioned a spectrum of hydrogen sources and potential uses for at-scale utilization as part of a strategy in which hydrogen is part of a future low-carbon economy in the US. It is unclear how the market for hydrogen as an energy carrier will develop and which sources and uses of hydrogen will be developed in the next several decades. But as hydrogen markets are developed, transportation and storage infrastructure will be critical considerations. The low energy density of hydrogen gas compared to natural gas by unit volume (H2 has 30% as much energy as natural gas) means any future transport and storage schemes will need to accommodate lower energy-density gas.

As a thought experiment, if 1% of current US natural gas consumption were replaced with hydrogen gas, then—assuming a 10% storage versus consumption ratio—roughly 100 bcf of storage for hydrogen gas would be required. If hydrogen gas were to replace 10% of US natural gas, 1 tcf of gas storage would be required.

Current H2 storage capacity is roughly 5–6 bcf. Hence, H2 storage would need to be increased by 20 times for a 1% replacement of H2 in the natural gas network and by 200 times for 10% replacement by H2 in the natural gas network based on 2019 natural gas consumption. Some of the storage could displace current natural gas storage and some new storage would need to be developed depending on how the H2 gas would be used.

Hydrogen into the gas system

Although depending on the end usage and market, dedicated, pure hydrogen supply may be required, a gas mixture (admixture) with a low percentage (< 10%) of H2 is potentially feasible for power generation and thermal heating with current technology. A trial in Germany conducted 2012-14 demonstrated that admixture of up to 10% H2 in a natural gas grid could be safely used for thermal appliances (e.g., water heaters, boilers, cookers) without adverse impacts. Although this pilot was limited to a small grid of 2,000 residents, the pilot demonstrated that low-percentage replacement of H2 in gas grids is feasible.

Assuming that the H2 could be generated renewably or alternatively from fossil fuels using steam methane reforming (SMR) or gasification technologies with commensurate carbon capture and storage, a 10% H2–90% natural gas mix in the US natural gas grid would have an appreciable impact on reducing the country’s CO2 emissions. At the scale of natural gas consumption in the US grid, 85 bcfd, a 10% H2 mix would be 8.5 bcfd. Each bcf of natural gas contains approximately 53,000 tons of CO2. Hence, more than 450,000 tons/day of CO2 could be removed from US natural gas CO2 emissions, or about 165 million tons/year, 3.2% of the total US 2019 CO2 emissions of 5,130 million tons.

Admixing no-carbon or low-carbon generated hydrogen into the US natural gas grid may not be the preferred market option for hydrogen. But it is one path for using large volumes of hydrogen gas with current technologies.

System-scale infrastructure modeling

We envision a collaborative initiative to develop a dedicated hydrogen infrastructure system that takes advantage of the existing natural gas pipeline and storage system. A large-scale hydrogen sector requires dedicated and developed transportation and storage infrastructure. The gas infrastructure system in the US is the most expansive and connected gas network globally and could be used to transport and distribute renewable methane and hydrogen. If it were, it would be a bridge to a full-scale hydrogen economy in the US.

Cost-optimal hydrogen infrastructure must be estimated using different scenarios for projecting hydrogen supply and demand in the US, including development of a detailed infrastructure model of the entire US pipeline system and export capabilities via LNG and liquified hydrogen, as well as new pipeline and transportation options (trucks, barges, and trains). The intent is to leverage the comprehensive data and understanding of natural gas infrastructure to inform a baseline for building an infrastructure system for hydrogen.

Development of hydrogen markets will require modeling hydrogen infrastructure systems that simulate delivery and storage of hydrogen from production to market. The models will include the entire database of production by site and type within the North American market and a downstream demand study covering all existing and evolving hydrogen applications.

This modeling system dedicated to the hydrogen value chain leverages the existing knowledge and abilities of the oil, gas, and chemical industries, as well as their existing physical assets (pipelines, storage fields, refineries). This leveraging of known systems provides a robust and quantifiable foundation for simulating and assessing focused technology choices related to hydrogen.

Market potential can be measured through market size, willingness to pay based on existing alternatives, and established value chain margins, and inform economic, energy, and environmental changes required to use hydrogen fuel instead of alternative energy sources. These analyses would identify the industries that could use hydrogen fuel, and the type of hydrogen supply source that would make the most economic and technical sense in the context of demand characteristics and requirements and location of the industry.

Modeling would help develop a path for each application and industry’s possible plans to evolve and adapt to hydrogen fuel from established and existing market conditions. Although many hydrogen applications are being developed and the economics and cost competitiveness of these applications may improve over time, it is critical to establish a realistic view of demand development and the potential of both new and existing industrial applications and sectors regarding the adoption of hydrogen fuel.

The market demand outlook will shift and improve over time as the technology matures, however having an overall projection of demand would help industry and government stakeholders and policymakers determine and assess value chains from production to storage to transportation. The projection of demand will help inform design of a hydrogen economy aligned with downstream market adaptation and development.

Acknowledgment

The authors would like to thank Dr. Larry W. Lake at the University of Texas at Austin for his ongoing collaboration and guidance on in situ combustion. We also thank Guin McDaid at the Bureau of Economic Geology for preparing the maps of the natural gas grid and would like to express our appreciation to members of the media team at the Bureau of Economic Geology, Travis Hobbs, Jana Robinson, Francine Mastrangelo, and Jason Suarez, for editing and graphics support.

Bibliography

Alley, W.M., “Desalination of ground water—earth science perspectives,“ US Geological Survey Fact Sheet 075-03, 2003, p. 4.

Camp, D.W., “A review of underground coal gasification research and development in the United States,” Lawrence Livermore National Laboratory, technical report prepared for US DOE under contract no. AC52-07NA27344, 2017, p. 125.

Deymi-Dashtebayaz, M., Ebrahimi-Moghadam, A., Pishbin, S. I., and Pourramezan, M., “Investigating the effect of hydrogen injection on natural gas thermo-physical properties with various compositions,” Energy, Vol. 167, Jan. 15, 2019, p. 235–245.

Hajdo, L.E., Hallam, R.J. and Vorndran, L.D.L., “Hydrogen generation during in-situ combustion,” Society of Petroleum Engineers California Regional Meeting, Bakersfield, Calif., March 27–29, 1985.

International Energy Agency (IEA), “The future of hydrogen—seizing today’s opportunities,” report prepared for the G20 summit, Osaka, Japan June 28-29, 2019.

Javadpour, F., Singh, H., Babaei, M., and Enayati, S., “Gas flow models in shale—a review,” Energy Fuels, Vol. 35, No. 4, Feb. 3, 2021, p. 2999–3010.

Johnson, K.S., and Gonzales, S., “Salt deposits in the United States and regional geologic characteristics important for storage of radioactive waste,” Oklahoma Geological Survey Open-File Report 18-2018, 1978, p. 188.

Leicher, J., Nowakowski, T., Giese, A., and Görner, K., “Power-to-gas and the consequences—impact of higher hydrogen concentrations in natural gas on industrial combustion processes,” Energy Procedia, Vol. 120, August 2017, p. 96–103.

Lord, A.S., Kobos, P.H., and Borns, D.J., “Geologic storage of hydrogen—scaling up to meet city transportation demands,” International Journal of Hydrogen Energy, Vol. 39, No. 28, Sept. 23, 2014, p. 155570–15582.

Naraghi, M.E., Javadpour, F., and Ko, L.T., “An object-based shale permeability model—non-Darcy gas flow, sorption, and surface diffusion effects,” Transport in Porous Media, Vol. 125, Jan. 4, 2018, p. 23–39.

Netherlands Enterprise Agency, “The effects of hydrogen injection in natural networks for the Dutch underground storages,” contract report, Publication No. RVO-079-1701/RP-DUZA, 2017, p. 66.

National Energy Technology Laboratory, “Carbon Storage Atlas (5th ed.),” Washington, DC, US DOE Office of Fossil Energy, 2015, p. 114.

Nitschke-Kowsky, P. and Wessing, W., “Experience with the injection of hydrogen into a historically grown natural gas distribution grid,” International Gas Union Research Conference, Copenhagen, Sept. 17–19, 2014.

Railroad Commission of Texas, “The application of Air Liquide Large Industries US LP for authority pursuant to Statewide Rule 97 for a permit to create, operate and maintain an underground hydrocarbon storage facility, Air Liquide Storage Facility Lease, Spindletop Field, Jefferson County, Texas,” Oil and Gas Docket No. 03-0258152, 2008, p. 5.

US DOE, “Hydrogen strategy—enabling a low-carbon economy,” Office of Fossil Energy, 2020, p. 24.

US Energy Information Agency (EIA), “The Basics of Underground Natural Gas Storage,” 2015.

US EIA, “EIA-191 Monthly Underground Gas Storage Report,” 2021.

The authors

Mark W. Shuster ([email protected]) is an associate director at the Bureau of Economic Geology, University of Texas at Austin. Mark has been at the bureau since 2016 after a 30-year career at Shell in exploration and exploration research as a geologist, manager, vice president, and executive vice president. He holds a Ph.D. (1986) from The University of Wyoming and a BS from The University of the Pacific, Stockton, Calif. He is a member of the American Association of Petroleum Geologists (AAPG), Geological Society of America, the 2021 president of the Gulf Coast Association of Geological Societies, and the vice-chair of the American Geosciences Institute Foundation.

Shuvajit Bhattacharya ([email protected]) is a researcher at Bureau of Economic Geology, The University of Texas at Austin. He has also served as faculty of applied geophysics at the University of Alaska-Anchorage. He holds a Ph.D. (2016) from West Virginia University. He is a member of AAPG and the Society of Exploration Geologists (SEG).

Ian Duncan ([email protected]) is a program director at the University of Texas at Austin. He was formerly associate director of the Bureau of Economic Geology at UT. He previously served as associate professor at Washington University in St Louis and research associate at Stanford University, Calif. He holds a Ph.D. in Geology (1980) from the University of British Columbia and a BA with first-class honours in geology (1974) from Macquarie University in Sydney, Australia.

Peter Eichhubl ([email protected]) is a senior research scientist at the University of Texas at Austin. He has also served as assistant professor at Texas A&M University-Corpus Christi and research associate at Stanford University. He holds a Ph.D. in Geology (1997) from the University of California, Santa Barbara, and an MS in geology (1989) from the University of Vienna, Austria. He is a member of the Geological Society of America, American Geophysical Union (AGU), Geological Society London, and AAPG.

Seyyed Hosseini ([email protected]) is research scientist at Bureau of Economic Geology, University of Texas at Austin. He has also served as reservoir simulation engineer at Kelkar and Associates. He holds a Ph.D. (2008) from The University of Tulsa. He is a member of Society of Petroleum Engineers (SPE), Society for Porous Media, and American Geophysical Union.

Farzam Javadpour ([email protected]) is a research scientist at the Bureau of Economic Geology, Jackson School of Geosciences, the University of Texas at Austin. He has also served as research scientist at Alberta Innovates-Technology Futures. He holds MS (2001) and Ph.D. degrees (2006) from the University of Calgary. He is a member of the SPE, AAPG, Interpore, and American Institute of Chemical Engineers (AIChE).

Jay Kipper ([email protected]) is associate director at the Bureau of Economic Geology at the University of Texas at Austin. He has also served as a vice president at Aspen Technology. He holds a chemical engineering degree from Trinity University in San Antonio, Tex.

Ning Lin (ning.lin@ beg.utexas.edu) is chief economist at the Bureau of Economic Geology, University of Texas at Austin. Before joining the bureau in 2018, Ning spent 15-years in market analysis and business development roles for Shell Trading, Invista-Koch Industries, and Tenaska covering the chemical and energy industries. She holds a Ph.D. in economics from University of Texas at Austin (2011) and a BS in economics from Byrn Mawr College (2002), Pennsylvania. She is a member of the US Association for Energy Economics, International Association of Energy Economics, and has served on its business committee since 2017.

J.-P. Nicot ([email protected]) is a senior research scientist at The University of Texas at Austin Bureau of Economic Geology (Jackson School of Geosciences). He has also served as a geosystems engineer at Duke Engineering and, earlier, as an exploration geologist. He holds a BS in geological engineering from Ecole Nationale Supérieure de Géologie Appliquée, Nancy, France (1981) and an MA in geological sciences (1995) and Ph.D. in civil engineering (1998), both from The University of Texas at Austin. He is a member of SPE, AGU, and the National Groundwater Association.

Bo Ren ([email protected]) is a reservoir engineer (research associate) at Texas Bureau of Economic Geology, Austin. He holds a Ph.D. (2017) in petroleum engineering from the University of Texas at Austin. He is a member of SPE and AGU.