Scale prevention device minimizes wellhead flowline fouling

Abdelaziz A. Noaman

Halliburton

Abu Dhabi, UAE

He Li Xin

Enmax Technology (Shanghai) Co. Ltd.

Biggen, China

Farid Chemil

Rabah Djanati

Sonatrach

Hassi Messaoud, Algeria

Scale inflicts water injection restrictions primarily under conditions of incompatible waters.1-6 Typical examples include sea water with a high concentration of sulfate ion, and formation waters with high concentrations of calcium, barium, and strontium ions. Mixing these waters can precipitate calcium sulfate, barium sulfate, or strontium sulfate.7-10

To determine if passive scale prevention devices (SPD) reduce scale deposition in wellhead flowlines, devices were installed on two wells in Hassi Messaoud field in Ouargla Province, Algeria. Samples were taken upstream and downstream of the scale device and analyzed for total suspended solids (TSS) and water quality. Upstream and downstream scale coupons evaluated the device’s scale inhibition capability and showed as much as a 44% reduction in scale.

Scale concerns

Scale formation in surface and subsurface oil and gas production equipment is a major operational problem. It has been also recognized as a major cause of formation damage either in injection or producing wells and contributes to equipment wear, corrosion, and flow restriction.11 12

Scale mainly exists in inorganic and organic classifications. They are mutually inclusive, occurring simultaneously in the same system and referred to as mixed scale and have highly complex structures that are difficult to treat. 13 These scales require aggressive, severe, and sometimes costly remediation.14 Paraffin, wax, asphaltenes, and gas hydrates are the most often encountered organic scales in the oil industry.15

Inorganic scales refer to mineral deposits that occur when the formation water mixes with brines such as injection water. Mixing reacts incompatible ions and changes the thermodynamic and equilibrium state of the reservoir fluids. Supersaturation of the inorganic salts results in scale deposition.16 17 The most common types of inorganic scales in the oil and gas industry are carbonates and sulfates, however sulfides and chlorites are also often encountered.18

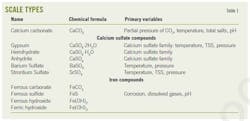

Table 1 shows typical scales which are encountered in oil and gas production including sulfates such as calcium sulfate (anhydrite, gypsum), barium sulfate (barite), strontium sulfate (celestite), and calcium carbonate. Other less common scales have also been reported such as iron oxides, iron sulfides, and iron carbonate.19-21

Calcite deposition is generally a self-scaling process. The main driver for its formation is the loss of CO2 from the water to the hydrocarbon phase as pressure falls. This removes carbonic acid from the water phase which had kept the basic calcite dissolved. Calcite solubility also decreases with decreasing temperature (at constant CO2 partial pressure).22-24

Iron sulfide scales are almost ubiquitous when hydrogen sulfide is produced and are frequently the result of tubular corrosion in the presence of H2S.25

Scale deposition occurs in water injection systems primarily when two incompatible waters are involved. Typical examples are sea water with high concentration of sulfate ion and formation waters with high concentrations of calcium, barium, and strontium ions. Mixing of these waters, therefore, could cause precipitation of calcium sulfate, barium sulfate (BaSO4), or strontium sulfate. BaSO4 scale forms as an odorless white crystalline solid which is insoluble in water.26 27 Scale prevention using chemical inhibitors, applied either by continual injection or by squeeze treatment into the near wellbore formation, has generally been regarded as the most cost-effective solution to the problem, but BaSO4’s physical hardness and chemical and thermal stability makes it one of the most difficult types of scale to inhibit.28

Scale prevention

To study and evaluate the efficiency, suitability, and capability of an SPD to solve the scale formation and production shortfalls, two devices were installed in Hassi Messaoud field on the 6-in. wellhead flowline of Well MD287 and initially on the 8-in. section of a 6-in. x 8-in. wellhead flowline of Well MD525 (the SPD was subsequently relocated to the 6-in. section of the flowline).

Hassi Messaoud is the largest oil field in Algeria, about 650 km southeast of Algiers and covering about 2,000 sq km, divided into two north and south fields. It includes more than 1,000 wells and was developed and is currently operated by Algerian state-owned Sonatrach. Total proven reserves are about 870 × 106 tonnes (6.4 billion bbl) and it produces about 56,000 cu m/day (350,000 bo/d). Most associated gas is reinjected into the reservoir to improve oil recovery and, more recently, this has been augmented with gas from the other fields in the region.

The SPD comprises a series of internal elements to prevent scale, paraffin, asphaltene, and rust.29 It includes nine dissimilar metals such as copper, zinc, and nickel, which form a catalyst to change the electrostatic potential of the fluids. The change in potential polarizes the liquid and reduces binding between the negative and positive ions and between suspending particles. This catalytic action keeps particles suspended and inhibits ions from binding to each other to form scales or paraffin deposits. It will also break down the existing paraffin or scale deposit to flush away with the fluids. Table 2 lists the working conditions of the device.

The device is non-magnetic, non-electrical, requires no chemicals, and is suitable for high-pressure, high-temperature operations. It has no additional chemical costs and can be installed downhole or on surface lines.

Field tests

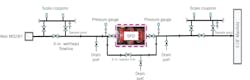

Fig. 1 shows the installation of the SPD at the 6-in. wellhead flowline of Well MD287. The device was installed through welding flanges, and the material specifications matched the specifications of the pipeline. A bypass line isolated the device in case of failure or inspection. Pressure gauges installed upstream and downstream of the device monitored device plugging or other flow problems.

Total suspended solid (TSS) and water quality measurements upstream and downstream of the device determined SPD scale prevention effectiveness. Likewise, upstream and downstream scale coupons measured scale produced from the well (upstream) and scale reduction by the device (downstream). Scale coupons and water sample points were installed 300 m upstream and 1,000 m downstream of the device. A post-test inspection visually recorded the total amount of deposits accumulated in the flowline upstream and downstream of the SPD.

SPD results

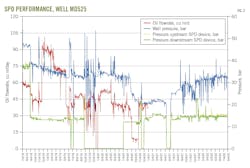

Table 3 lists oil, gas, and water flowrates for both wells based on the most recent well tests. Gauges installed upstream and downstream of the SPD recorded pressures daily. The device exhibits 0-bar pressure drop when operating properly, but operating procedures required isolating the device for inspection and maintenance if the pressure drop increased to 2 bar.

Fig. 2 shows upstream and downstream pressure across the device, wellhead pressure, and oil flowrate from Well MD525. The figure shows no pressure difference across the scale device from July to August, at which point the pressure differential dramatically increased. The device was removed and disassembled for internal inspection. An accumulation of deposits on the internal plates of the original SPD design produced the pressure differential. The SPD vendor made changes to the internal design and sent new parts which were installed within the original SPD casing (Fig. 3). The device was subsequently placed back in service. A similar situation occurred in the original SPD design installed in Well MD287.

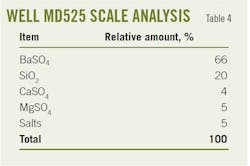

The weight of scale formed on the downstream coupon in Well MD525 after 6 months of exposure was 37 mg, and the weight on the upstream coupon was 58 mg. The device thus reduced scale by 44%. The scale was comprised of 78% BaSO4, 18 % organic material, 2% oxides, and 2% carbonate (Table 4).

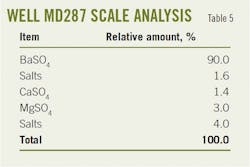

The weight of scale formed on the downstream coupon in Well MD287 after 6 months of exposure was 30 mg, while 34 mg formed on the upstream coupon. These deposits represented low concentrations of BaSO4 which were not significantly reduced by the SPD. Table 5 shows components of the scale in Well MD287, which are like components in Well MD525 but more concentrated in BaSO4.

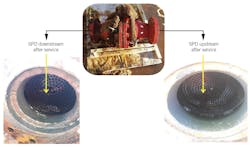

Figs. 4 and 5 show the pipeline upstream and downstream of the SPD in both wells. Significant scale deposited upstream of the device in both wells, with more deposits in MD525, which correlates with the higher mass of scale recorded on coupons in Well MD525 relative to Well MD287.

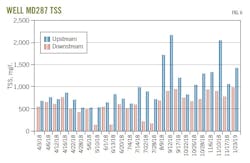

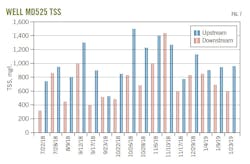

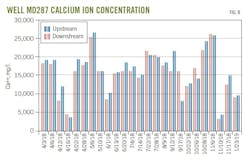

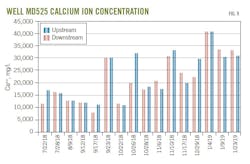

Figs. 6–7 show TSS and Figs. 8–9 show calcium ion (Ca++) concentrations for both wells, upstream and downstream of the devices. Upstream TSS for both wells are generally the same, averaging about 600 mg/l. Downstream TSS is higher than upstream TSS. The SPD prevents formation of scales by breaking bonds between particles, raising downstream TSS levels. Likewise, the calcium ion concentration downstream of the devices is higher than the upstream concentration, showing that the devices are breaking up calcium scales and increasing Ca++ concentrations in solution.

References

- Chen, T., Wang, Q., Chang, F., and Aljeaban, N., “Recent Development and Remaining Challenges of Iron Sulfide Scale Mitigation in Sour Gas Wells,” International Petroleum Technology Conference¸ Beijing, Mar. 26–28, 2019.

- Hashemi, S.H. and Hashemi, S.A., “Prediction of Scale Formation According to Water Injection Operations in Nosrat Oil Field,” Model. Earth Syst. Environ., Vol. 6, No. 2, October 2019., pp. 585–589.

- Ali, A.M. and Messaoud, H., “Barium Sulphate Deposits,” Energy Procedia, Vol. 157, 2019, pp. 879–891.

- Al‑Samhan, M., Alanezi , K., Al‑Fadhli, J., Al‑Attar , F., Mukadam , S., and George, J., “Evaluating Scale deposition and Scale tendency of effluent water mix with seawater for compatible injection water,” Journal of Petroleum Exploration and Production Technology, Vol. 10, No. 1, 2020, pp. 2105–2111.

- Hamid, K.M., Elgibaly, A.A., and Fekry, M.H., “The Possibility of Using Sea Water Injection into Petroleum Reservoirs and Reducing Their Scale Precipitation in Injection and Production Pipelines,” Petroleum & Coal, Vol. 61, No. 5, 2019, pp. 1047–1054.

- Azizi, J., Shadizadeh, S.R., Manshad, A.K., and Jadidi, N., “Effects of pH and Temperature on Oilfield Scale Formation,” Iranian Journal of Oil & Gas Science and Technology, Vol. 7, No. 3, 2018, pp. 18–31.

- Ghasemian, J., Riahi, S., Ayatollahi, S., and Mokhtari, R., “Effect of Salinity and Ion Type on Formation Damage Due to Inorganic Scale Deposition and Introducing Optimum Salinity,” Journal of Petroleum Science and Engineering, Vol. 177, June 2019, pp. 270–281.

- Bageri, B., Mahmoud, M., Shawabkeh, R., Al-Mutairi, S., and Abdulraheem, A., “Toward a Complete Removal of Barite (barium sulfate BaSO4) Scale using Chelating Agents and Catalysts,” Arab. Journal of Science & Engineering., Vol. 42, No. 4, February 2017, pp. 1667–1674.

- Lu, A.Y., Wang, W., Venkatesan, R., Harouaka, K., Paudyal, S., Saebom ,K., Dai, C., Gao, S., Deng, G., Zhao, Y., Wang, X., Kan, A.T., and Tomson, M., “The Mechanism of Barium Sulfate Deposition Inhibition and the Prediction of Inhibitor Dosage,” Journal of Chemical & Engineering Data, Vol. 64, No. 11, Nov. 5, 2019, pp. 4968–4976.

- Gurbanov, G.R., Adygezalova, M.B., Pashayeva, S.M., and Abdullayeva, N.A., “Effectiveness of Preventing Scale using an Inhibitory Composition in Laboratory Conditions,” Oilfield Business, Vol. 4, No. 604, 2019, pp. 66–69.

- Chao, Y. and Wei, W., “Dissolution Study of Field Deposits for Oilfield Scale Mitigation and Remediation,” SPE International Conference on Oilfield Chemistry, Galveston, Tex., Apr. 8–9, 2019.

- Lilya, S., Dmitry, T., and Rahman A., “Prevention of Scale in the Downhole Equipment and Productive Reservoir During the Oil Well Operation,” Journal of Applied Engineering Science, Vol. 19, No. 2, 2021, pp. 363–368.

- Li, J., Tang, M., Ye, Z., Chen, L., and Zhou, Y., “Scale formation and control in oil and gas fields: A review,” Journal of Dispersion Science and Technology, Vol. 38, Vol. 5, May 2016, pp. 661–670.

- Al Rawahi, Y., Shaik, F., and Lakkimsetty, R., “Studies on Scale Deposition in Oil Industries & Their Control,” International Journal for Innovative Research in Science & Technology, Vol. 3, No. 12, May 2017.

- Yan, Y., Tao, Y., Song, J., Wu, B., and Qu, C., “A Review of Prediction Methods for Oilfield Produced Water Scaling,” 3rd International Conference on Green Energy and Sustainable Development, Shenyang City, China, Nov. 14–15, 2020.

- Askar, M., Abdallah, A., and Gad, I., “Downhole Scales Associated with October Field Formation Waters and Water Injection Using a Shallow Aquifer,” SPE International Conference and Exhibition on Formation Damage Control, Lafayette, La., Feb. 19–21, 2020.

- Rezaee, A., Nejad, A., and Mansouri, H., “Scaling and Corrosion in Oil Production-How Do They Relate to Each other?,” International Journal of Engineering and Applied Sciences, Vol. 4, No. 6, July 2017, pp. 40–43.

- Kamal, M.S., Hussein, I., Mahmoud, M., Sultan, A.S., and Saad, M., “Oilfield scale formation and chemical removal: A review,” Journal of Petroleum Science and Engineering, Vol.171, December 2018, pp. 127–139.

- Olajire, A.A., “A Review of Oilfield Mineral Scale Deposits Management Technology for Oil and Gas Production,” J. Pet. Sci. Eng., Vol. 135, September 2015, pp. 723–737.

- Mohammad, A. and Mazumder, J., “A Review of Green Scale Inhibitors: Process, Types, Mechanism and Properties,” Coatings Journal, Vol.10, No. 10, Sept. 28, 2020.

- Zheng, H. and Chunsheng, P., “Comprehensive Research of Scaling Prediction for Gas Reservoir Fluid considering Phase State,” Article ID 5067345, Hindawi Geofluids, Vol. 2019, Feb. 11, 2019.

- Hamid, S., De Jesus, O., Jacinto, C., Izetti, R., Pinto, H., Droguett, E., Edwards, C., Cassidy, J., Zhang, H., Dagenais, P., and Batocchio, M.A., “A Practical Method of Predicting Calcium Carbonate Scale Formation in Well Completions,” SPE Production & Operations, Vol. 31, No. 1, February 2016, pp. 1–11.

- Jain, T., Sanchez, E., Owens-Bennett, E., Trussell, R., Walker, S.L., and Liu, H., “Impacts of Antiscalants on the Formation of Calcium Solids: Implication on scaling potential of desalination concentrate,” Environmental Science Water Research & Technology, Vol. 5, May 8, 2019, pp.1285–1294.

- Wang, X., Deng, G., Ko, S., Lu, A.Y., Zhao, Y., Dai, C., Paudyal, S., Ouyang, B., Mateen, S., Kan, A.T., and Tomson, M.B., “Improved Scale Prediction for High Calcium Containing Produced Brine and Sulfide Scales,” SPE International Oilfield Scale Conference and Exhibition, virtual, June 24–25, 2020.

- Chen, T., Wang, Q., Chang, F., and Aljeaban, N., “Recent Development and Remaining Challenges of Iron Sulfide Scale Mitigation in Sour Gas Wells,” International Petroleum Technology Conference¸ Beijing, China, March 26–28, 2019.

- Erin, T., Myles, J., Helen, W., Sigrid, K., Marija, K., and Johansen, K., “Development of a Barium Sulphate Scale Inhibitor for Chalk Solid Loaded Conditions,” SPE International Conference on Oilfield Chemistry, Galveston, Tex., April 2019.

- Sahar, R., Nor, R., Mohamad, W., Amni, W., Khan, R.A., Farima, E., and Hatta, S.A., “Selection of Barium Sulphate/Barite Dissolver Chemical through Establishment of Standard Laboratory Screening Protocols,” Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, November 11–14, 2019.

- Lilya, S., Dmitry, T., and Rahman A., “Prevention of Scale in the Downhole Equipment and Productive Reservoir During the Oil Well Operation,” Journal of Applied Engineering Science, Vol. 19, No. 2, Spring 2021, pp. 363–368.

Authors

Dr. Abdelaziz Noaman ([email protected]) is a senior process & flow assurance consultant for Halliburton for Hassi Messaoud field in Algeria. He holds a PhD in chemical engineering (2018) from Minia University, Egypt.

He Li Xin ([email protected]) is a sales expert for Enmax Technology (Shanghai) Company, Ltd. He holds a BS degree (1994) and a PhD (2003) from the University of Science and Technology of China (USTC).

Farid Chemil ([email protected]) is the director of Hassi Messaoud field in Algeria for Sonatrach. He holds a BS (1995) in petroleum engineering from Bomerdas University, Algeria.

Rabah Djanati ([email protected]) is a process manager for Hassi Messaoud field in Algeria for Sonatrach. He holds a BS (2006) in petroleum engineering from Bomerdas University, Algeria.