Deepwater trial tests low-dosage hydrate inhibitor

In a deepwater field test, Shell Exploration & Production Co. says it demonstrated that low-dosage hydrate inhibitors (LDHIs) provide effective flow assurance.

Its presentations at the recent Offshore Technology Conference in Houston indicated that LDHIs are an alternative to thermodynamic hydrate inhibitors, such as methanol and glycol. Although methanol and glycol are proven inhibitors, the logistics of transportation and storage have a negative impact on operating and capital expenditures, according to Shell.

Need for inhibition

Both subsea gas and oil flowlines require some hydrate inhibition, especially in deepwater environments. Typical gas flowlines do not have insulation and require continuous methanol or glycol injection for hydrate inhibition. Oil flowlines, on the other hand, are typically insulated but require hydrate inhibitors for start-up and shut-in restarts.

A presentation at OTC by A.P. Mehta, Shell Global Solutions (US) Inc., P.B. Hebert, Shell E&P Co., E.R. Cadena, Shell Global Solutions, and J.P. Weatherman, Shell E&P Co., said that particularly in deepwater environments such as the Gulf of Mexico and West Africa, hydrate inhibition and control often form the basis for designing deepwater developments.

The presentation indicated that fields in this environment are susceptible to hydrate formation because of their high reservoir pressures and low seabed temperatures.

It further added that even in shallow water environments in the North Sea, hydrate management issues often dictate the system selection and topsides design.

During early field life, water cuts are generally low but increase as the field matures. Consequently, fields need larger methanol or glycol volumes later in their life.

According to the presentation, there is also a significant push from refineries to limit the allowable concentration of methanol in the produced oil or condensate. High methanol concentrations in the oil can cause problems in desalting operations and management of effluent streams.

The presentation said producers also are reducing methanol content in gas because of severe penalties incurred for deviating from gas plant specifications.

Methanol problems become more acute during events such as a hurricane shut-in when operators bullhead in several barrels of methanol into the tubing of oil wells. Upon re-start, downstream problems can be caused by the methanol slug.

LDHI development

For more than a decade, both academia and industry have investigated the phenomenon in which certain fish do not freeze in subzero temperature waters because a protein secretion binds itself on microscopic ice crystals and prevents the growth of subsequent crystals.

This observation led Shell to develop the new class of hydrate inhibitors for preventing the formation and accumulation of large hydrate crystals that would result in hydrate blockage (Fig. 1).

Shell claims the antiagglomerant (AA) LDHI it developed provides inhibition at operating conditions of 35° F. inside the hydrate stability region.

It says these AA LDHIs also provide some kinetic hydrate inhibition and are sometimes referred to as hydrate growth inhibitors (HGIs) that provide protection for subcoolings of 40° F. and higher.

Shell explains that the dosage rate of the LDHIs is lower compared to methanol or glycol, with volume reductions greater than 25 times. This allows for less topsides storage space, easier transportation, and smaller umbilicals. Elimination of bulky topsides equipment reduces development costs, and the smaller treatments by volume reduce operating expenses, according to Shell.

LDHIs also eliminate discharge of methanol in the overboard water as well as in the oil and gas export lines.

In 1998, Shell licensed its LDHI technology to Baker Petrolite Corp.

Popeye test

Shell tested its LDHI technology in its Popeye field in 2,000 ft of water in the Gulf of Mexico Green Canyon Blocks 72, 73, 116, and 117 (Fig. 2). The four-well development has dual 6-in. ID carbon-steel flowlines tied-back 24 miles to the Couger platform on South Timbalier Block 300. Duplex stainless steel 4-in. ID jumpers connect the subsea wells to the manifold (Fig. 1).

Production started from the initial two wells in January 1996. The development added a third well in 1997 and a fourth well in 2002.

The initial design expected production to be 120 MMscfd with associated gas condensate, but Shell indicates production rates from three wells have reached 167 MMscfd and 9,000 b/d of condensate.

To inhibit hydrates during the initial years of production, it injected methanol into each flowline from the three wells (A1, A2, and A3). But in early 2001, it needed to increase methanol volumes because Popeye had started producing formation water at a rapidly increasing rate. It, therefore, decided to conduct a field trial of AA LDHI to evaluate the inhibitors' effectiveness in actual deepwater operating conditions.

For the test, Shell first conducted in-house tests with a hydrate cell immersed in a temperature-controlled bath. Before the test, Popeye's production had decreased to 60 MMscfd, 3,000 b/d of condensate, and 430 bw/d. The meth anol injection rate was 175 b/d.

Shell says the switchover from methanol to LDHI was seamless, with no unexpected increase in flowline pressure.

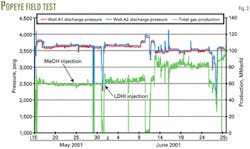

Over a 24-hr period, it slowly added LDHI while decreasing methanol injection rates until all methanol injection into the flowline stopped and the system was operating solely on LDHI (Fig. 3).

As part of the test, it shut in production for 24 hr and restarted production without any problems. It says the shut-in test demonstrated that a continuous treatment with LDHI before shut-in eliminates the need for instantaneous corrective measures during the restart of production.

It currently treats Popeye's flowlines with only LDHI and production is more than 100 MMscfd, 3,000 b/d condensate, and 1,500 bw/d. Shell estimates the change to LDHIs will add a net 7.5 bcf to the recovery from the field, resulting in an $8 million net present value (NPV) increase.