BLACK POWDER—Conclusion: Management requires multiple approaches

Effective control of black powder usually requires a combination of several management methods varied for each specific case. Several removal and prevention methods can help gas pipeline operators mitigate and manage black powder’s effects.

Black powder occurs globally. It is regenerative, forming inside natural gas pipelines as their internal walls corrode, and spurred by the reaction of iron (Fe) in ferrous pipeline steel with condensed moisture containing oxygen (O2), hydrogen sulfide (H2S), and carbon dioxide (CO2). These chemicals are benign in dry sales gas but can become corrosive when dissolved in water.

In sales-gas transmission pipelines exposed to oxygen contamination, black powder consists primarily of iron hydroxides, iron oxides, and small amounts of iron carbonates. Contaminants such as sand, dirt, hydrocarbons, elemental sulfur, and metal debris typically make up 20 wt % of black powder. Black powder’s jagged shape and high hardness erode pipeline control valves. In pipelines transporting untreated sour natural gas, black powder consists primarily of iron sulfides.

The first part of these two articles (OGJ, Aug. 11, 2008, p. 54) reviewed recent laboratory and field work conducted at Saudi Research and Development Center to determine the composition, sources, and formation mechanisms of black powder in gas transmission systems. Microhardness, nano-indentation, x-ray diffraction (XRD), x-ray fluorescence (XRF), and scanning electron microscopy (SEM) techniques, as well as several bacterial analysis methods analyzed black powder samples collected from the field.

This concluding article describes black powder’s physical and mechanical properties and presents a summary and brief discussion of various black-powder management methods.

Properties

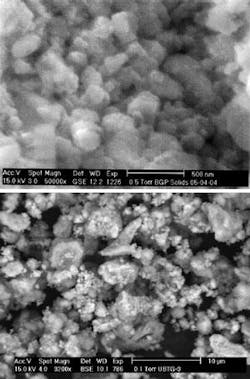

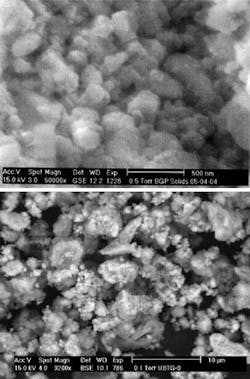

The accompanying photograph shows scanning electron microscopy (SEM) images of dry and wet black powder. Both black powder samples consist of fine, jagged particles. X-ray diffraction (XRD) analysis further confirmed the average particle size of black powder as less than 100 nanometers.

Microhardness measurements conducted on both pipeline steel and black powder revealed average Vickers hardness values of 179±10 VHN (87±2 Rb) and 498±62 VHN (49±4 Rc), respectively. Hardness measurements conducted on black powder particles with the nano-indentation technique revealed an average hardness value of 475±162 VHN (47±10 Rc).

These results show both hardness measurement techniques provide comparable hardness values for black powder, and black powder is harder than carbon steel (the hardness of black powder is in the Rockwell C range, while pipeline steel has hardness in the Rockwell B range). The large standard deviation in hardness measurements with the nano-indentation technique stems from the differing composition of the particles (iron oxides or iron carbonates), known to have different hardness values.

Management methods

Gas pipeline companies practice various methods to manage and control black powder in their systems. These methods reside in two categories: removal methods and prevention methods.

Removal

Pipeline companies have observed the presence of black powder and its effects for years but have viewed it primarily as a nuisance and therefore done little to understand and prevent it. This has led most management efforts to focus on removal of black powder rather than prevention. Removal methods include:

• Mechanical cleaning. Mechanical pigs scrape debris from the pipeline wall and remove black powder. This method may keep the pipeline fairly clean when black powder has not been a major problem. This method, however, cannot address large quantities of black powder.

• Chemical cleaning. Several chemical cleaning agents can remove black powder from gas pipelines. Gel and surfactant cleaners are used most frequently. Gel can carry large amounts of solids, but dealing with large gel batches becomes difficult when cleaning has to be done online. Removal of gel residues from the pipeline also requires extra attention.

With a proven record in removing black powder, surfactants can dissolve in diesel or organic solvents. Dissolution in water should be avoided to prevent exposing the pipeline to water. Surfactants can penetrate contaminants, lowering the surface tension properties of pipelines and removing large amounts of black powder.

• Separators. Separators and cyclones use centrifugal force. Black powder-laden gas passes through them and the particles are physically knocked out of the gas stream to the walls of the separator where they collect in a hub at the bottom. This method only works if the concentration of solid particles is relatively high and particle size is relatively large (>8-10 µm).

• Filters. These usually consist of cartridges placed downstream of the gas pipeline to protect control valves and customers. The design and size of these filters depends on the amount of black powder, its particle size, and hardness.

• Cyclo-Filters. These combine the best features of cyclones and filters in a two-stage removal process. The cyclone knocks out black powder particles larger than 8-10 µm in the first stage. The second stage consists of cartridge filters that remove finer particles.

Each of these methods can work separately or in combination. For example, mechanical cleaning by instrument scraping can combine with installation of filters downstream. This combination ensures the scraped black powder gets filtered out from the gas supply before reaching customers.

Although removal approaches protect downstream operations and customers from black powder’s effects, they have several common drawbacks:

- They are after-the-fact treatments and do not address the root cause of black powder.

- They require subsequent handling and disposal procedures and processes.

- They require frequent applications.

- They often require multiple units, as in the case of filters and cyclones.

- They add to the ongoing operational costs of gas transport systems.

Prevention methods

Prevention methods start with the premise that internal corrosion of gas pipelines causes black powder and then seek to prevent the corrosion. These methods include:

• Moisture control. Eliminating water condensation in the pipeline is critical in preventing black powder formation. Improving efficiency of the gas dehydration process ensures dry gas in the pipeline.

Appropriately sized triethylene glycol (TEG) dehydration units coupled with installation of appropriately sized refrigeration and knockout drums upstream and downstream of these units, respectively, will ensure drier gas entering the gas lines. Controlling and minimizing process upsets such as water and TEG carryovers also play an important role in limiting pipeline moisture. Appropriately sized, designed, and maintained molecular sieves and chillers might be expensive, but they ensure drier gas.

Strict adherence to sales gas standards would ensure elimination of condensed water in internally bare pipelines and in turn prevent black powder formation. Process upsets, however, would still allow excess moisture into the delivery network, leading potentially to condensation and internal corrosion. Networks with multiple gas treatment plants feeding into them are particularly vulnerable due to the potential cumulative effects of process upsets. A gas network connected to seven plants, for example, each of which suffered one 3-day outage/year would be exposed to a potential of 21 days of moisture condensation.

• Internal coatings. Organic coatings, such as high-solids solvent based epoxy polyamine films, reduce drag but have the added benefit of preventing black powder. Typical application measures 2-3 mil (50-80 μm) thick to cover pipe roughness (Ry5 = 30 μm). Used globally for 55 years in more than 300,000 km of pipelines, they have good ageing properties, showing no degradation after 30 years exposure to dry.

International Standards (API 5 L 2 and ISO 15741) cover specifications of internal coating for gas pipelines. Internal coatings are a cost-effective means of preventing black powder in new pipelines. They are, however, very difficult to apply and not cost effective in existing pipelines, particularly buried pipelines.

• Commissioning practices. Improving dewatering and drying procedures during hydrotesting by flash drying with methanol or nitrogen instead of air drying can help prevent black powder formation.

The use of sweet water with biocides and corrosion inhibitors will prevent corrosion during hydrotest shut-in periods. If sweet water is not readily available in the field, as is the case in many Middle Eastern regions, fresh water slugs run between pigs will wash the line and remove salt water. Chemical cleaning should follow hydrotesting in sales-gas transmission pipelines to ensure the pipeline is free of loose debris and mill scale before operations start.