Drilling Market Focus: Singapore leads in current jack up construction

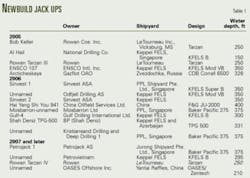

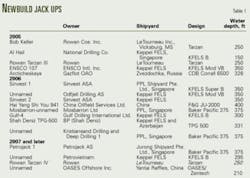

Strong worldwide demand for rigs has companies placing orders for newbuilds. Drilling contractors and operators took delivery of 17 new jack ups from 2000-04 (OGJ, Dec. 20, 2004, p. 39) and 15 more are under construction, scheduled for completion in 2005-07. Additional contracts are under discussion (Table 1).

Singapore leads in the construction of jack up drilling rigs, scheduled for delivery in 2000-07. Keppel FELS Energy & Infrastructure Ltd. and SembCorp Marine Ltd., a division of SembCorp Industries, have seven and four jack ups, respectively, under construction in Singapore. SembCorp Marine is building jack ups at two of its four Singapore shipyards: PPL Shipyard Pte. Ltd. and Jurong Shipyard Pte. Ltd.

Two jack ups are being built at Letourneau Inc.'s yard in Vicksburg, Miss., and one each in China and Russia.

Companies have also scheduled at least 10 other jack ups for upgrades.

Utilization, SCORE

According to the 2005 Global Offshore Drilling Outlook, published in December by ODS-Petrodata Group, there was a net increase of 16 working jack ups in the worldwide fleet in 2004. Utilization of jack ups worldwide for the week ending Dec. 31, 2004, was 90.4%, up from 90.1% the week of Dec. 17. Utilization of the Gulf of Mexico jack up fleet was 81.8%, with about 90 rigs under contract.

GlobalSantaFe Corp.'s monthly Summary of Current Offshore Rig Economics shows that offshore day rates continue to increase worldwide. The overall worldwide SCORE in November 2004 was 52.9, up 11% from the previous month, up 32% from the previous year, and up 120% compared with 5 years ago.

The SCORE for jack ups worldwide was 58, up nearly 6% from the previous month, up 23% from a year ago, and up 130% over the past 5 years.

SCORE compares the profitability of current mobile offshore drilling rig day rates to the profitability of day rates at the 1980-81 peak of the offshore drilling cycle.

US—Rowan

Houston-based Rowan Cos. Inc. runs 26 jack ups, including the second and third Tarzan rigs under construction. The first Tarzan rig, the Scooter Yeargain, was delivered in April 2004 (OGJ, Dec. 20, 2004, p. 39). The company is focusing on equipment for shallow water, deep gas drilling.

The Bob Keller will probably launch in midyear and be delivered in September 2005 from the LeTourneau yard in Vicksburg, Miss. (Fig. 1). It will be capable of drilling to 30,000 ft in 250-ft water.

null

Steel has been cut for the Rowan Tarzan III, but the keel will not be laid until late in first-quarter 2005, with rig delivery sometime in 2006, according to Rowan. The fourth rig is planned, but no work has yet begun on the Rowan Tarzan IV.

US—ENSCO

Dallas-based ENSCO International Inc. has 44 jack up rigs worldwide, including two newbuilds and four undergoing modifications. The company reported that the average contract rate for its jack up rigs was $54,800/day in third-quarter 2004, compared with $48,400 a year earlier.

The ENSCO 107 jack up is under construction at Keppel FELS yard in Singapore and will be delivered in late December 2005. The rig is an enhanced KFELS Mod V (B) design, customized to ENSCO specifications. The modified rig design is called "Bigfoot."

The Bigfoot derrick is 170 ft tall and can support a hook load of 1.5 million lb. It has a 3,000-hp Varco ADS-10DT drawworks and a Varco TDS 82A top drive with a Varco PH-100 pipe handling system. The rig has three Lewco W-2215 mud pumps each rated to 7,500 psi.

ENSCO funded construction of the ENSCO 107 with $55 million in cash and transferred three older ENSCO rigs, a jack up and two platform rigs, to Keppel FELS.

Its sister rig, the ENSCO 106 jack up, has also been under construction at Keppel FELS. It was delivered in December 2004 and will be commissioned this month.

The ENSCO 106 and 107 will each cost about $105 million, although the construction agreements are unique. The ENSCO 106 was built as a joint venture between ENSCO and Keppel FELS, wherein ENSCO acquired 25% ownership for $26.25 million in cash and project management services. ENSCO has an option to purchase the remaining 75% interest for 2 years after delivery, according to company press releases.

ENSCO and Keppel FELS had a similar financing agreement for the ENSCO 102 jack up (total cost $125 million), under which ENSCO purchased the outstanding 75% interest for $95 million in first-quarter 2004, just months before the 2-year option period expired (OGJ, Mar. 22, 2004, p. 37).

Among the four jack ups being modified in January 2005 are the ENSCO 67 (slot to cantilever conversion at Keppel FELS shipyard in Singapore; redelivery scheduled for May 2005); ENSCO 84 (cantilever, Gulf of Mexico upgrade); ENSCO 95 (Hitachi C-250, being upgraded at the Lamprell shipyard in United Arab Emirates); and the ENSCO 100 (enhanced Gorilla rig, undergoing maintenance in Nigeria).

Four more jack ups are scheduled to begin upgrades later in 2005, according to ENSCO. The rig ENSCO 87 improvements will begin in first-quarter 2005 and take about 9 months to complete. "Life refurbishment" upgrades for the ENSCO 99, 89, and 86 will take about 4 months for each rig. The company has not decided on plans for the ENSCO 64, upgraded with a new drilling package at the AMFELS yard in 2001, but damaged in Hurricane Ivan.

In addition to jack ups undergoing or scheduled for modification, the ENSCO 68 jack up recently underwent an extensive, $50 million conversion in the AMFELS yard in Brownsville. The LeTourneau design rig was originally built in 1976, but ENSCO told OGJ that the recent replacement of more than 400 tonnes of steel has considerably extended its life.

The conversion work also included a slot to cantilever conversion and a third 1,600-hp mud pump with an enhanced mud volume and solids control system. The rig received a new derrick with 1.5 million lb hook load capacity and was modified for zero discharge drilling. After the modifications were finished in early November 2004, the ENSCO 68 went to work in the Gulf of Mexico for Houston-based Pogo Producing Co. at a contract of more than $60,000/day.

ENSCO's 11-year upgrade program will have cost about $1.2 billion when it is completed at the end of this year.

Zentech rigs

Engineers at Houston-based Zentech Inc. have created two designs for a new type of multi-service, self-propelled jack up vessel with removable drilling apparatus, capable of working in water up to 210 ft deep. A removable rig package enables such a vessel to work in construction, diving support, pipe-laying, or as a tender-assist unit. Typical Gulf Coast lift boats have increased in size over the years but are subject to storms and poor maneuverability.

One design was produced, pursuant to an October 2000 agreement with Covington, La.-based Oases Offshore Inc. A schematic of this design on Oases Offshore's website shows a cantilevered rig on a rectangular deck with three legs, three cranes, and 18,000 ft of deck space. According to a June 2003 press release from the Yantai Raffles shipyard in China, the yard has a contract to build one of the Zentech/Oases jack ups, executed with a Nigeria-based representative of Oases Offshore.

Zentech's second design, the Z-210, is designed to mobile offshore drilling unit (MODU) specifications and follows MODU survivability rules. Zentech says the four, 1,500 hp, fully azimuthing thrusters will provide better maneuverability than a typical lift boat. The vessel has 1,814 tonnes variable load capacity, including 907 tonnes on the 20,000 sq ft open deck. The Z-210 has four triangular legs, each 3211/2 ft long.

Zentech also has new designs for standard jack ups, the Zentech R-450 and Zentech Z-636, utilizing the Zenlock leg locking system.

Norway—Skeie

Sinvest ASA, a subsidiary of Norway's Skeie Group AS, has three jack ups under construction in Singapore. Two are at Keppel FELS yard in Singapore, scheduled for 2006 delivery, and one jack up at PPL. The Sinvest 1, 2 are both KFELS Super B Class rigs, capable of drilling in 350 ft water to a depth of 35,000 ft at high pressures (to 15,000 psi) and high temperatures (to 130º C.).

The first contract was signed in January 2004 for $126 million with construction expected to take 26 months and provided an option for a second rig, according to Marinelog.com. The second contract was signed in July 2004 for an additional $126 million.

Sinvest has a third jack up under construction at SembCorp Marine's PPL Shipyard, Singapore. The rig was commissioned by Kristiansand Drilling Pte. Ltd. in a $110 million engineering-procurement-construction contract in January 2004. Delivery is expected in first-quarter 2006.

Kristiansand has a complex ownership. SembCorp Marine subsidiary Sembawang Shipyard Pte. Ltd. created Kristiansand as a single purpose joint-venture company. Kristiansand is owned by SempCorp (82%) and Skeie Group (18%, through Skeie subsidiary Deep Drilling 1 Pte Ltd.). Skeie Group SA is a private company owned by the Skeie family.

The Kristiansand rig will be a Baker Marine Pacific Class 375 design independent leg cantilever jack up, capable of drilling in 375-ft water to 30,000 ft (Fig. 2). The design incorporates Baker Marine's proprietary jacking system and the rig will be equipped for high- pressure, high-temperature drilling.

Other Norwegians

Odfjell Drilling AS, based in Bergen, Norway, announced a rig construction program in March 2004. According to the company's 2003 annual report, one jack up is under construction at the Keppel FELS yard in Singapore and options are in place to build two more jack ups. The rig is scheduled for May 2006 delivery and will be the first jack up to join the company fleet of three semisubmersibles and eight platforms. It will be owned by Bermuda-based Odfjell Invest Ltd. of which Odfjell Drilling has a 40.8% share. Odfjell Drilling will supervise construction, market, and operate the rig.

The new Odfjell jack up is a KFELS Mod V-B Class design, capable of drilling in water as deep as 350 ft to a depth of 30,000 ft. The rig will have a 70-ft cantilever extension and 15-ft port-starboard transverse movement capability. The AC-powered jack up will feature a 3,000-hp drawworks and support a maximum variable load of 3,356 tonnes and maximum combined drilling load of 886 tonnes. It will accommodate 110 persons.

Norway's Mosbarron Ltd., an Awilco affiliate, has a Baker Marine Pacific Class 375 jack up under construction at the PPL Shipyard, Singapore. Delivery is planned for second-quarter 2006. According to the Singapore Shipping Times, May 2004, the construction contract is for $117.6 million. The contract includes options for three more jack ups. Baker Marine Pte. Ltd. is a subsidiary of PPL.

On Nov. 26, 2004, Norway's Bergens Tidende reported that privately held Petrojack AS, Bergen, commissioned a new jack up from SembCorp Marine's Jurong shipyard. The total cost is reported as $135 million (840 million kroner), of which 213 million kroner will be financed with private equity capital, arranged by First Securities ASA and ABG Sundal Collier ASA.

PetroJack founder and chairman Berge Gerdt Larsen owns 30% of the company. Larsen also founded Larsen Oil & Gas AS and is the chairman and main shareholder of DNO ASA.

The PetroJack rig will be a Baker Marine Pacific Class 375, the third contract placed for this design. Construction of the rig will begin first-quarter 2005 and is to be complete in second-quarter 2007. The contract contains options to build two additional, similar jack ups. The options expire in December 2005 and June 2006.

Middle East, Caspian

National Drilling Co. (NDC) of Abu Dhabi has one jack up, the Al Hail, under construction at Keppel FELS in Singapore for $110 million, due for delivery in 2005. The FELS B class rig is designed for water depths up to 150 ft.The company has nine other jack ups, eight of which are working under UAE flag for Abu Dhabi Marine Operating Co. NDC's Al Ittihad jack up, under Panama flag, is currently undergoing modifications at a Lamprell yard in UAE.

Keppel FELS recently contracted with Gulf Drilling International Ltd. (GDI), Qatar's first national drilling company, to build a KFELS B Class jack up for $110 million. The rig will be capable of drilling in 300 ft water.

According to a November 2004 news release by Qatar National Bank (QNB), the new joint venture company, GDI, has received $50 million in financing to fund initial construction of the new jack up and to purchase and upgrade a second jack up. GDI currently has four offshore units and two land rigs and plans to invest up to $300 million through 2006 to upgrade its fleet. GDI was created in April 2004 in a $258 million agreement between Qatar Petroleum (60%) and Japan Drilling Co. (40%). The Qatar government owns 50% of QNB.

Doha-based GDI began operations in June 2004 with a $64-million contract with Qatar Petroleum for the Gulf-1 jack up (previously Japan Drilling Co.'s Hakuryu-8). The drilling company began its second contract with QP, worth $27 million, drilling with the GDI-1 land rig in December 2004.

Keppel associate Arab Heavy Industries PJSC (AHI) is currently upgrading and refurbishing two jack ups: the Gulf-2 for GDI, and the NPCC SEP-350 for National Petroleum Construction Co.

BP Exploration (Shah Deniz) commissioned a self-installing drilling and production jack up for Caspian Sea condensate development in a $96 million contract with Keppel FELS, based on Tehnip's proprietary TPG 500 design. KFELS delivered the main hull sections of the Shah Deniz platform to BP on July 26, 2004. This is the third TPG-500 platform constructed; the first two are offshore UK for Britoil PLC (BPAmoco) and Elf Exploration Ltd.

The four hull strips will be integrated with other modules in a floating drydock in Baku, under a $20 million contract with KFELS and Caspian Shipyard Co., a subsidiary of Keppel Offshore & Marine. The rig is scheduled for completion in third-quarter 2006, according to the September/October 2004issue of Keppel Offshore Marine.

The TPG 500 will be deployed in the Shah Deniz gas-condensate field about 100 km south of Baku; the primary sales market for the gas is in Turkey.

In April 2003, Keppel began setting up a new offshore engineering and construction facility in Aktau. The new company, Keppel Kazakhstan LLP, was established as a 50:50 joint venture with Kazakh investors. Phase 1 of the facility development is estimated at about $20 million, about half the total cost. Bill Kee, CEO of Keppel Kazakh- stan told OGJ in December 2004 that Phase 1 is ongoing and includes preparing the site, developing infrastructure, and purchasing equipment.

null

The first project for the new yard will be to build an offshore oil platform for the AgipKCO consortium's giant Kashagan oil field.

This is Keppel's second shipyard in the Caspian. The Keppel yard at Baku has generated about $600 million in business since it was established in 1997, according to John Chan, general manager of international business at Keppel Offshore & Marine Ltd.

China

In September 2003, China Oilfield Services Ltd. (COSL) signed a contract with Houston-based Friede & Goldman LLC for design of the Hai Yang Shi You 941 jack up, an F&G JU-2000 now under construction in China. The COSL rig will incorporate F&G's advanced rack chock operating system (ARCOS). COSL also has an option for construction of a second rig (OGJ, Sept. 20, 2004, p. 45).

On July 29, 2004, COSL announced its contract to buy Singapore KS Tech Ltd.'s Kuril jack up for $33 million. The rig is a CDB Korrall model built in 1993 at Vyborg Shipyard, Russia, and recently renamed the COSL 931.

Viet Nam

Petrovietnam Drilling & Well Services Co. (PV Drilling) has ordered a new KFELS B-Class jack up in a $110 million contract, according to an early January news release from Keppel FELS. PV Drilling's parent company, Vietnam Oil and Gas Corp. (Petrovietnam) is Vietnam's national oil company. It operates two jack ups (Tam Dao; Cuu Long) and one platform rig through Russo-Vietnamese joint venture Vietsovpetro.

The new jack up will be capable of operating in 295 ft water depth, drill to 20,000 ft, and accommodate 110 persons. It is scheduled for delivery in first quarter 2007.

Russia

The Arcticheskaya jack up is under construction in Russia for Gazflot OAO, the offshore subsidiary of Gasprom, with possible delivery in 2005. According to Rigzone, the new rig is a CDB (Central Design Bureau) Corrall 6500 design, capable of drilling in 330-ft water. The rig is probably destined for work in the Russian Arctic.

Construction of the jack up began in March 1995 at the Zvezdochka shipyard in the port of Severodvinsk on the White Sea. The Arcticheskaya is one of two independent leg cantilever jack ups designed for Gazprom by Kvaerner Oil and Gas Russia and NPO Zvezdochka, each costing $100 million (OGJ, Sept. 23, 1996, p. 56).

According to a January 2004 article in Russian Shipbuilding,1 the rig partly sank in May 2001 due to "partial depressurization of the hull," but was raised in August 2001. Construction of the Arcticheskaya was about one-third complete as of January 2004; Gazprom, Zvezdochka, and KB Corrall have modified the original design.

Arcticheskaya jack up construction was reportedly on hold in 2004 in favor of funding the completion of the ice-resistant Prirazlomnaya drilling platform at Sevmashpredpriyatie (Sevmash), large shipbuilding complex at Severodvinsk. The platform is intended for the Prirazlomnoye field in Pechora Bay, Barents Sea. Platform construction began in 1997, and the project had an estimated cost of $800 million with an estimated 2001 completion date.2

Gazflot owns one other jack up, the four-legged Amazone, operated by Amidco. The rig is a Gusto design built in 1982 by Aker Oslo at Storde in Norway, flagged in Benin, and currently cold-stacked. Gazflot leased the rig to drill in the Kara Sea in 2002 and subsequently purchased it.

According to a 2002 report by the Russian news agency Pravda, Gazprom began a 6-year prospecting program on the Kara Sea shelf in 2000. The program will cost about $420 million and will include 35 test wells, a seismic program, and engineering geology study.

The only other Russian jack up, the Murmanskaya, owned by Murmansk-based Arktikmorneftegazrazvedka (Arktikmor), is a CDB Corrall design. The Murmanskaya last drilled exploratory wells in Medy-More oil field, Pechora Sea, during summer 2004, according to a BizBarents report on Nov. 15. The rig is currently cold-stacked.

Artikmor, or AMNGR, is a Federal State Unitary Enterprise (FSUE), founded as a trust on July 1, 1979, "for conducting works on prospecting, exploration, and development of oil and gas fields on the Arctic Seas shelf."3

Support vessels

The growing rig fleet has put increasing demand on service and support vessels. Accordingly, service companies have dozens of vessels under construction.

Tidewater Inc. owns and operates 439 supply vessels worldwide and in fourth-quarter 2004 took delivery of the first of five deepwater anchor-handling towing supply boats. The company has 20 additional vessels under construction, at a cost of about $314 million. Tidewater says it will spend $150-200 million/year on construction.

In December, the company's average US contract rate for deepwater vessels (supply and anchor-handling towing) was $12,577/day, and future contracts are more than $13,000/day. Towing and supply vessels averaged $5,794/ day, but leading-edge rates are close to $6,200/day. Outside of the US, as of mid-December, deepwater rates averaged $12,200/day, and towing and supply vessels averaged $6,250/day.

In a Dec. 20, 2004, report, Lehman Bros. analysts say that most of the newbuild vessels outside of Tidewater's fleet are in the Far East, with a focus on construction of midsize units. They believe that E&P activity outside the US will cause increases in utilization and day rates for supply vessels in 2005.

References

1. http://shipbuilding.ru/eng/ news/2004/01/27/star; source: Dvina Inform.

2. www.globalsecurity.org/ military/world/russia/severodvinsk.htm

3. www.amngr.ru/ index3e.htm