Oil & Gas Journal reported on the Jan. 18 explosion at Petroleo Brasileiro SA's 323,000-b/d Landulpho Alves refinery in Sao Francisco do Conde, Bahia, Brazil (OGJ Online, Jan. 19, 2015). Also in this news story was information about a Jan. 14 fire that broke out in the refinery's U-30 normal paraffin unit with production capacity of 1,300 cu m/day.

Reading this story made this editor curious about the history of paraffin and its uses. Paraffin, a byproduct of petroleum distillation, found its way from refinery to marketplace in the form of candles, crayons, sealing waxes, and American candies.

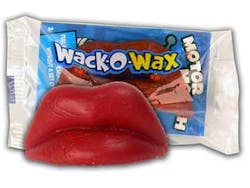

John W. Glenn, a confectioner from Buffalo, NY, used fully refined, food-grade paraffin to find a niche in America's imagination. His business boomed when he introduced children to paraffin penny chewing gum novelties, according to the American Oil & Gas Historical Society. By 1923, JW Glenn Co. employed 100 people, including 18 traveling sales representatives. The company later became the wax candy division of Franklin Gurley's nearby W&F Manufacturing Co. Wax lips and wax horse teeth were among the most popular of these novelties at the time. Today, Concord Confections, a small part of Tootsie-Roll Industries, continues to produce wax lips and other paraffin candies.

Oil field crayons

By 1903, Binney & Smith Co. was ready to launch a new product that would change childhood forever. Alice Binney, a school teacher and wife of the founder, coined the name Crayola by combining the French word, craie, for chalk, with ola for oily, oleaginous.

Manufacturing was based on small batches of carefully measured and hand-mixed pigments, paraffin, talc, and other waxes. Paper labels were individually rolled by hand and pasted onto each crayon.

The finished products were hand-packed into individual boxes and shipped in wooden crates. Sixteen Crayola crayons sold for 10¢; eight for 5¢: red, yellow, orange, green, blue, violet, black, and brown.

Binney & Smith produced the first box of eight Crayola crayons in 1903-red, orange, yellow, green, blue, violet, brown, and black.

Oil field paraffin from distant petroleum refineries is now delivered to Crayola's Easton, Pa., factory in railroad tank cars. Production capacity is more than 4 million crayons every day.

Potting guitar pickups

By 1939, Gurley was producing a popular series of holiday candles for the Socony-Vacuum Oil Co. using paraffin from a nearby refinery at Olean, NY, once home to the world's largest crude oil storage site. Paraffin candles became the company's principal products, accounting for 98% of W&F Manufacturing sales.

A popular use for these candles is potting guitar pickups, according to a How-To article in Premier Guitar magazine.

Potting pickups with wax has been going on for a long time, and was originally intended to attenuate feedback-loose coil windings that vibrate in sympathy with acoustic sound will induce that acoustic sound into the amplified signal and create a feedback loop.

Encase the pickup windings in wax, and the sound takes on more characteristics of the wood, with a rounder, fuller tone.

The article instructs to melt the candles in a saucepan, lower the pickup into the hot wax, let it soak for between one and two minutes, and wait about 30 min for them to cool down before reinstalling.

Paraffin represents a successful union of the petroleum industry and versatile products for modern consumers.

About the Author

Leena Koottungal

Survey Editor / News Writer

Leena Koottungal is the Survey Editor/News Writer for Oil & Gas Journal. She joined PennWell in April 2006.