Petroleum Industry Careers Start with Exploration

Oil and natural gas furnish about three-fifths of our energy needs, fueling our homes, workplaces, factories and transportation systems. In addition, petroleum serves as the raw material for plastics, chemicals, medicines, fertilizers and synthetic fibers. Petroleum is so ubiquitous that we tend to forget how essential it is. But have you ever contemplated a world without oil or natural gas?

Similarly, people are essential to the petroleum industry. The industry is so large, encompassing so many segments and activities that it is easier viewed as a collection of industries-that translates into vast needs for people with a variety of backgrounds and interests . . . and that, in turn, translates into tremendous career opportunities.

It all starts with exploration. Using a variety of methods, on land and at sea, specialized professionals search for geologic formations that may contain oil and gas. Sophisticated equipment and advances in computer technology have increased the productivity of exploration. Maps of potential deposits are made using remote-sensing satellites.

Seismic prospecting-a technique based on measuring the time it takes sound waves to travel through underground formations and return to the surface-has revolutionized oil and gas exploration. Computers and advanced software analyze seismic data to provide three-dimensional models of subsurface rock formations. This technique lowers the risk involved in exploring by allowing scientists to locate and identify oil and gas reservoirs and the best locations to drill. Four-D, or “time-lapsed,” seismic technology tracks the movement of fluids over time and helps enhance production.

Another method of searching for oil and gas is based on collecting and analyzing core samples of rock, clay and sand in the earth’s layers. After scientific studies indicate the possible presence of oil, an oil company selects a well site and installs a derrick-a tower-like steel structure-to support the drilling equipment. A hole is drilled deep into the earth until oil or gas is found, or the company abandons the effort. Similar techniques are employed in offshore drilling, except that the drilling equipment is part of a steel platform that either sits on the ocean floor, or floats on the surface and is anchored to the ocean floor. Although some large oil companies do their own drilling, most land and offshore drilling is performed by contractors.

In rotary drilling, a rotating bit attached to a length of hollow drill pipe bores a hole in the ground by chipping and cutting rock. As the bit cuts deeper, more pipe is added. A stream of drilling “mud”-a mixture of clay, chemicals, and water-is continuously pumped through the drill pipe and through holes in the drill bit. Its purpose is to cool the drill bit, plaster the walls of the hole to prevent cave-ins, carry crushed rock to the surface and prevent “blowouts” by equalizing pressure inside the hole. When a drill bit wears out, all drill pipe must be removed from the hole a section at a time, the bit replaced, and the pipe returned to the hole. New materials and better designs have advanced drill bit technology, permitting faster, more cost-effective drilling for longer periods.

Advancements in directional or horizontal drilling techniques, which allow increased access to potential reserves, have had a significant impact on drilling capabilities. Drilling begins vertically, but the drill bit can be turned so that drilling can continue at an angle of up to 90 degrees. This technique extends the drill’s reach, enabling it to reach separate pockets of oil or gas. Because constructing new platforms is costly, this technique commonly is employed by offshore drilling operations.

When oil or gas is found, the drill pipe and bit are pulled from the well, and metal pipe (casing) is lowered into the hole and cemented in place. The casing’s upper end is fastened to a system of pipes and valves called a wellhead, or “Christmas Tree,” through which natural pressure forces the oil or gas into separation and storage tanks. If natural pressure is not great enough to force the oil to the surface, pumps may be used. In some cases, water, steam or gas may be injected into the oil-producing formation to improve recovery.

Crude oil is transported to refineries by pipeline, ship, barge, truck or railroad. Natural gas usually is transported to processing plants by pipeline. While oil refineries may be many thousands of miles away from the producing fields, gas processing plants typically are near the fields, so that impurities-water, sulfur and natural gas liquids-can be removed before the gas is piped to customers. The oil refining industry is considered a separate industry, and its activities are not covered here, even though many oil companies both extract and refine oil.

A History of Booms and Busts

The oil and gas extraction industry has experienced both “booms” and “busts” over the years, illustrating the cyclical relationship between the price of oil and employment. Generally, the reaction of the labor market lags slightly behind the price fluctuations because oil companies must adjust their production levels accordingly.

During the 1970s and early 1980s, the price of crude oil rose sharply, stimulating domestic exploration and production. Between 1978 and 1982-the year in which industry employment peaked-the oil and gas extraction industry grew 65 percent, creating 279,000 jobs, while employment in the economy as a whole remained flat.

Starting in 1982, oil-producing countries around the world began pumping much larger volumes of crude oil, driving prices down; this culminated in the collapse of oil prices in the mid-1980s. During this time, the industry experienced a sharp decline in domestic exploration and production and an extended period of downsizing and restructuring, losing more than 415,000 jobs from 1982 to 1999. High oil prices in 2000 through 2003 led to small gains in employment.

Employment in the 21st Century

The oil and gas extraction industry, with about 123,000 wage and salary jobs in 2002, is the largest industry in the Bureau of Labor Statistics’ mining division, accounting for one-quarter of employment. Although onshore oil and gas extraction firms are located throughout the United States, more than 77 percent of the industry’s workers in 2002 were located in just four states-California, Louisiana, Oklahoma and Texas.

While most workers are employed on land, many work at offshore sites. Although they are not included in employment figures for this industry, many Americans are employed by oil companies at locations in Africa, the North Sea, the Far East, the Middle East, South America, and countries of the former Soviet Union.

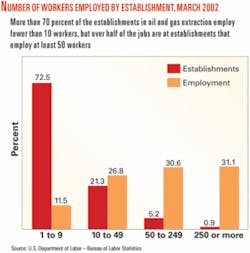

About 7 out of 10 firms employ fewer than 10 workers, although more than 60 percent of all workers in this industry are employed in establishments with greater than 50 workers (see chart). As more large domestic oilfields and gasfields are depleted, major oil companies are focusing their exploration and production activities in foreign countries. Consequently, smaller companies with less capital for foreign exploration and production are drilling an increasing share of domestic oil and gas. Technology also has significantly decreased the risk and cost for smaller producers.

Relatively few oil and gas extraction workers are in their teens or early 20s. About 55 percent of the workers in this industry are between 35 and 54 years of age. As the industry workforce continues to age, career opportunities are becoming greater for entry-level candidates.