DCS advanced control improves Chinese ethylene cracker operation

Honggang Wang

Zhenlei Wang

Hua Mei

Feng Qian

East China University of Science and Technology

Shanghai

Zhiwu Tang

Sinopec Yangzi Petrochemical Co. Ltd.

Nanjing, China

China Petroleum & Chemical Corp. (Sinopec) improved ethylene crackers operations, increased desirable olefin product yields, and reduced fuel consumption by implementing DCS-resident advanced control strategies at ethylene crackers in its five ethylene plants.

The conservatively estimated quantifiable benefits of the project for the crackers amount to nearly $4 million/year for a typical 700,000-tonnes/year ethylene plant, with payback of less than 1 month.

Background

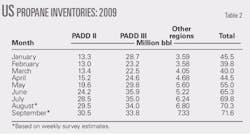

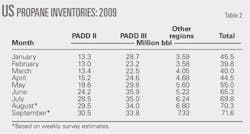

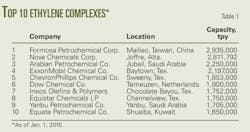

Ethylene capacity in China has doubled during 2005-10 in response to strong domestic demand. China has ranked second in the world in terms of ethylene production capacity since 2005, and the gap with the US is narrowing. As the largest ethylene producer in China, Sinopec became the fifth largest ethylene producer worldwide in 2010 (OGJ, July 26, 2010, p. 34), while it was seventh in 2005 (OGJ, Mar. 28, 2005, p. 47).

In addition to capacity expansion, Sinopec planned to improve its plant operations to stay ahead in the fast changing and competitive market. At midyear 2007, Sinopec initiated this project as part of an "advanced process control (APC) promotion project for ethylene crackers and key columns in ethylene units" within its subsidiaries, including Shanghai, Qilu, Guangzhou, Tianjin, and Zhongyuan. Combined, these sites include 28 ethylene crackers, 7 ethylene fractionators, and 6 propylene fractionators.

East China University of Science and Technology worked as a long-term partner for Sinopec in this project. It has successively completed APC projects with sustainable benefits at the ethylene units of Yangzi (in Nanjing) since 1999 and Qilu (in Shandong) since 2000, including 27 crackers, 1 ethylene fractionators, and 4 propylene fractionators.

The model-based APC techniques1 have been widely applied in global hydrocarbon processes and especially in ethylene plants.2-5 Nevertheless, this project employed mainly proportional integral and derivative (PID)-based and nonlinear control techniques, or simple APC. Implementation included advanced regulatory control,6 expert systems,7 inferential control schemes8 based on process characteristics and instrumentation capabilities, maintenance ease, and realization of control benefits. The control solutions featured a high service factor, low maintenance, and ease of understanding and required no additional hardware or software.

This article discusses the APC implementation at the ethylene crackers and highlights the major contributions of this project.

Process description

A typical 700,000-tpy ethylene unit has 14 ethylene crackers with the capacity of each cracker ranging 30,000-100,000 tpy. Ethylene crackers convert hydrocarbon feeds, diluted with steam, into olefins. Feedstocks include heavy naphtha, light naphtha, hydrotreated vacuum gas oil, atmospheric gas oil, LPG (propane/butane), and ethane from the C2-splitter bottom. All feedstocks are preheated in the furnace's convection section, after which dilution steam is added to each feed pass and the mixture is fed to the multiple cracking coils vertically arranged in the furnace's radiant section.

The residence time in the cracking coils is normally 1 ms to 0.4 sec, depending on the furnace type. The coil outlet temperatures (COTs) are on the order of 790° C. to 850° C., depending on feed type and a furnace's cycle age. To quench the secondary reactions, the effluent is cooled rapidly to 350° C. to 450° C. in the transfer line exchanger (TLE).

The heat input for the endothermic reaction comes from the fuel gas (fuel oil) firing in bottom burners or sidewall burners or both. The methane and off gas from the recovery unit have been the main fuels for all furnaces and the C4 or natural gas serves as a complement.

Each coil has a feed-flow controller, dilution-steam flow controller of its own. Thermocouples at each coil outlet measure and calculate the average COT, which is the key manipulated variable for cracking severity. The coil outlet pressure (COP) cannot be directly controlled but is subject to cracking-gas compressor suction pressure, pressure drops in both the quench tower and TLE. Fuel gas to bottom firing and side firing can be controlled with separate flow controllers or pressure controllers.

Problem identification

Most ethylene plants of Sinopec were commissioned in 1980s. Although many have undergone continuous process improvement, expansion, and DCS upgrade, smooth control for temperature and throughput of the ethylene cracker continues to perplex operators.

Interviews with operations in one plant showed that they had installed APC systems but finally abandoned them. A high degree of operational flexibility and frequent feed-slate change were the major causes, while faulty instruments and poor maintenance were others.

Comprehensive investigations at each plant identified some existing major operating problems, control schemes, and disturbances, as summarized below.

The average COT could not be tightly controlled. The original COT was controlled to target by manipulating the fuel-gas flow rate (or pressure) to the firebox, which could not reject the disturbance caused by the fluctuations of fuel-gas composition, pressure, and temperature. Apart from the frequent variations of the fuel-gas heat value, the occasional throughput change by production schedule was another disturbance to the average COT control.

Balancing the outlet temperature of individual coils (called "coil temperature balancing") was difficult. The set point of COT for each coil was set by operators and controlled to targets by manipulating the hydrocarbon feed rate of its own. In other words, the COT for each coil was controlled separately and there was no explicit coil temperature balancing scheme.

This control strategy could rapidly stabilize COT of each coil, but it brought deviations to the desired hydrocarbon throughput. On the other hand, the uneven temperature distribution in each firebox zone and inadequate decoking in some coils would bring more challenges into the coil temperature's balancing target.

For each cracker, the throughput needs to be adjusted according to the feed availability and market situation. The original control for throughput interacts with the average COT control, which makes it difficult and sometimes impossible to achieve the desired throughput target.

Control objectives, strategies

The ultimate goal of various control schemes for ethylene crackers is to maintain target conversion and severity while honoring crackers constraints, such as minimum run length, throughput, and maximum valve positions. Constant conversion and severity promise a consistent product slate, which also stabilizes the recovery section, allowing it to run closer to constraints.

The product slate depends on the temperature profile, pressure profile, and residence time in the cracking coils. For an existing furnace, smooth control of average COT, coil outlet temperature balancing, throughput and steam/hydrocarbon (S/HC) ratio are the foundation for the severity control and optimization.

A kickoff meeting with the process managers of each ethylene plant defined the scope of control system for the ethylene crackers, which includes the average COT control, coil outlet temperature balancing control, and throughput control. The expected control objectives are summarized as follows:

- The average variance for average COT should be ±1.5° C.

- The average variance for each coil temperature difference should be ±1.5° C.

- The average variance for total feed rate should be ±0.25%.

Based on the problem identifications and interviews with both managers and operators in each ethylene plant, we have formulated a modular control system for the ethylene cracker, including the average COT control, COT balancing control, throughput control, and S/HC ratio control. Fig. 1 shows a general view for the control scheme. Partial change with varying degrees is allowed in the implementation according to management requirements and operation situation.

Average COT control

The aim of the average COT control system is to control the average COT tightly under the disturbance of throughput and fuel gas. The manipulated variable can be fuel-gas flow rate or pressure, depending on the instrument availability and reliability. The control algorithm is a combination of feed-forward control and feedback control.

The heat-value fluctuation caused by the composition, temperature, and pressure of the fuel can be detected and counteracted quickly by the heat value feed-forward control. Throughput variation and other disturbances can be rejected by manipulating the total fuel load for the cracker.

The heat value feed-forward prediction module consists of three parts.

The first is a heat-value inferential model that reconstructs the heat value of fuel into each cracker based on related measurable process variables in fuel-gas system. The second part is a calorimeter that provides heat quantity measurements for fuel gas.

The inferential model is recalibrated by the measurement of calorimeter with an error-checking logic that reduces the impact of calorimeter failures, which is the third part.

The inferential model has dual functions. One is to compensate the time delay of the measurement by calorimeter when it works well. The other is to provide consistent prediction of the fuel-gas heat value whenever the calorimeter goes wrong. Thus, the average COT control system can be ensured effectively to reject the disturbance caused by the fuel gas, in spite of the time delay and high fault rate of the calorimeter.

To stabilize the average COT for combined firing furnace, the bottom firing duty is adjusted to reject the disturbance from the throughput change, and the sidewall firing duty is regulated when other disturbances, such as the draft pressure fluctuation, occur.

During adjustment of the bottom or sidewall firing duty, the heat duty ratio between them changes accordingly. Different heat duty ratio leads to different flame length and temperature distribution in the firebox, which will cause different heat flux profile and tube wall temperature along the cracking coils.

Generally, a recommended heat-load ratio value has been provided by the furnace designers. This value is treated as optimum and all operations shall be in a constraint range determined by special tests. Once the constraint boundary for the heat duty ratio is violated, the temperature difference in the vertical direction of cracking coils will go up quickly leading to shorter run length for the ethylene cracker.

To ensure the operating heat duty ratio remains within the constraint boundary, an expert system with deep knowledge of firebox operations and burners arrangement has been developed. The system adjusts self-adaptively the heat load of the side firing and bottom firing to stabilize the average COT. Meanwhile, it prevents the heat duty ratio from violating the constraint boundary.

The bottom and sidewall firing duty can also be controlled independently whenever needed. The transfer process is smooth and easy. Even when operators override the expert system, the latter will still provide feedback and early warning information once the heat duty ratio approaches the constraint boundary.

Balancing, throughput control.

If the average COT control is viewed as a coarse-grained temperature control, then the COT balancing control can be regarded as a fine-grained temperature control. Uneven firing to cracking coils and inadequate decoking with different degrees in daily operations lead to unequal heat input to each coils and thus different COTs.

If the difference between each coil outlet temperature and the average COT goes up, then the coil with too low temperature will induce under-cracking with undesirably lower conversion and ethylene yield, while the coil with too high temperature will cause over-cracking, which accelerates the coking rate and shortens the run length of the ethylene cracker.

The COT balancing control system minimizes the temperature differences between each coil outlet temperature and the average COT by manipulating the corresponding coil feed rate. The COT balancing control works in conjunction with the throughput control by regulating feed rate of each coil through a nonlinear control module. The nonlinear control algorithm minimizes the effect of the throughput target change to the COT balancing control system.

For an ethylene cracker with six coils, there are six coil temperature-difference controllers (TDCs) and one throughput controller working together by operating with the set point of the six feed flow controllers.

Now suppose every controller is in normal operation and the target for throughput controller has been set by a process engineer. If a deviation between Coil A outlet temperature and the average COT is sensed, the TDC controller of Coil A adjusts the set point in feed rate controller of Coil A. The deviation between the target and measured throughput, the sum of all six set points value of feed flow controllers, can be quickly sensed by the throughput controller.

To reduce this throughput deviation to zero, the throughput controller redistributes the feed rate variation in Coil A to the other five coils. The change of feed rate will in turn cause deviation of TDC in the other five coils and each of them will repeatedly experience the similar control actions described above. This process will not stop until the COT for all coils and throughput reach a new equilibrium point.

The control scheme described above has been designed mainly for cases of pure gas feed and pure liquid feed cracking mode. Given the limitation of feed availability and market situation, many ethylene crackers in the ethylene plant have been designed to operate in cocracking mode. This necessitates the COT balancing control for the gas/gas cocracking and gas/liquid cocracking.

For case of cocracking, two independent control systems have been designed. Suppose lighter feedstock like ethane or LPG flows in three coils, while heavier feedstock like naphtha or gas oil flows in the other three coils. Coils with lighter feedstock requiring higher outlet temperature are grouped and treated as an independent system.

In this system, the COT balancing control scheme still works. The only difference is that the new average COT is averaged by three but not all the coils' outlet temperatures as before. For each coil with heavier feedstock, the COT was controlled to targets independently by manipulating the hydrocarbon feed rate of its own.

Faulty instrumention has been a major obstacle for APC implementations. If any of the flow meters go bad, the COT balancing control system can still work by operating the valve positions directly with a set of spare TDC controllers. The switch process is smooth due to the tracking design.

Controllers' performance

The application in Sinopec's Shanghai 700,000-tpy ethylene plant was selected to evaluate the performance of APC. There are 14 ethylene crackers with various capacities, ranging from 30,000 tpy to 100,000 tpy, in this plant. The APC for the first ethylene cracker began in May 2007; the last one completed in May 2008. The first commissioned ethylene cracker was in September 2007. The APC for ethylene crackers has been in continuous use since the completion.

The most common user comment has been that the APC is always on when the cracker is on stream, which can also be reflected by the high on line time of the applications. Fig. 2 shows the average on line time of APC for all the 14 furnaces in 2009. Normally the on line time is well above 97%, with only a few furnaces not reaching 97%.

The on line time of Cracker No. 1 to No. 4 at the new site is higher than for the others at the old site. This is primarily due to the newer equipment and instrumentation at the new site. Off-line time of these applications mainly results from instrumentation failure and special operations.

Another common user comment has been that operator workload has been substantially reduced and operator time saved can be spent on more profitable tasks. The effectiveness of the control scheme and comprehensive logic smoothes away the highly interactive multivariable control problems, which were difficult to handle manually by operators before.

The average variances for temperature and throughput have been substantially reduced after the APC implementation (see accompanying table). Tighter control of both the average COT and in each coil now allows a 2° to 4° C. higher COT than before. Precise throughput control now allows potentially more capacity. Further to illustrate the temperature control performance, Figs. 3 and 4 show the 96-hr history trends for average COT control and TDC control from DCS screens.

Benefits

Based on a post-audit analysis, the resulting quantifiable benefit is $4 million/year. The achieved benefits include 85% from the yield increase of desirable olefin products and 15% from the fuel-gas saving. The average increase of ethylene and propylene yield is 0.39%. The average decrease of the fuel-gas consumption is 0.53%. This is mostly due to the effective rejection of usual fuel-gas system and feed rate disturbances and more even temperature control in each coil. The payback period is less than 1 month.

One intangible benefit is the potential increase of run length for ethylene crackers. This is because the tighter control of both the average COT and TDC in each coil reduces the coking rate.

Another intangible benefit is the substantial reduction in operator workload. Before the APC project, operators were always busy with the COT and TDC, since the COT variance and run length of each furnace are major evaluation indices for their rewards and penalties. Besides, they have to make time for monitoring hundreds of other variables. After the APC project, they have more time to monitor, analyze, and control the dynamic process.

To date, this control scheme has been implemented in five ethylene plants of Sinopec, covering 55 ethylene crackers. The oldest set has performed effectively for more than 10 years. This technology can deal with standard ethylene crackers provided by worldwide manufacturing companies and also revamped or combined ethylene crackers.

Several features leading to this successful project are:

- Comprehensive logics and corresponding control theme considering every possible situation, such as the operational flexibility and faulty instruments, promise high service factor and little maintenance.

- Seamless integration of APC into DCS platform ensures high frequency of interaction with plant data and thus quick control cycle by seconds, which suffices for the fast reaction process in the cracking coils with residence time far less than 1 sec.

- All control strategies implemented within the DCS are fully open to the end user, which makes the maintenance of the applications easier than locating them in a supervisory computer.

- User friendly interface in accordance with the DCS interface facilitates the understandings of the control system and regular operations by operators.

- There are short project execution duration and high return on investment.

- There is no additional hardware and software needed.

Acknowledgment

This work was supported by National Natural Science Funds for Distinguished Young Scholar, National High-Tech Research and Development Program of China, Shanghai Key Technologies R&D Program.

References

1. Friedman, V.Z., "What is advance process control?" Hydrocarbon Processing, May 2005, p. 15; June 2005, p. 114; and July 2005, p. 19.

2. Chang, E., and Viducic, M., "Low-cost advanced process control project captures energy savings in utilities area," Hydrocarbon Processing, June 2010, p. 43.

3. Canney, William M., "Advanced process control powers developments in operations management," OGJ, Nov. 8, 2004, p. 50.

4. Boell, M., et al., "Optimizing ethylene plant production using model predictive control and dynamic real time optimization," Proceedings of AIChE Spring Meeting, New Orleans, Apr. 25-29, 2004, p. 1192.

5. Sowers, G., et al., "Multivariable control and on line optimization of an ethylene plant," Proceedings of AIChE Spring Meeting, Houston, Mar. 14-18, 1999, p. 850.

6. Qian, F., et al., "Intelligent control technique for cracking furnaces in ethylene plant," CN1316484, October 2001 (in Chinese).

7. Liu, M.D., et al., "Soft sensing system of fuzzy-neural network for cracking fuel gas enthalpy," Computer Integrated Manufacturing Systems, May 2003, p. 412 (in Chinese).

8. Wang, Z.L., et al., "Intelligent control technique for ethylene plant," Chemical Industry and Engineering Progress, December 2006, p. 1454 (in Chinese).

The authors

Honggang Wang ([email protected]) is a PhD student in East China University of Science and Technology, Shanghai. His experience includes design, configuration, and commissioning of APC and RTO projects, data analysis, and neural network-based inferential model development. He holds a BS (2005) from China University of Petroleum, Beijing.

Zhenlei Wang ([email protected]) is a full professor in East China University of Science and Technology, specializing in advanced control. He has served as lead control engineer on several advanced process control projects and received his BS (1997) and PhD (2002), both in industrial automation from Northeastern University, Shenyang.

Hua Mei ([email protected]) is a lecturer at East China University of Science and Technology, specializing in advanced control. He has served as control engineer on several advanced process control projects, such as ethylene crackers, ethylene distillation, and propylene distillation. He received a BS (1999) from North China Electric Power University and PhD from Shanghai JiaoTong University, both in industrial automation.

Feng Qian ([email protected]) is a full professor and vice-president of East China University of Science and Technology with extensive project experience in design and implementation of DCS-resident APC, inferential control, and optimization strategies as applied to petrochemical processes (olefins, aromatics, specialty chemicals). He holds a BS (1988) and PhD (1995), both in industrial automation, from East China University of Science and Technology.

Z. Tang ([email protected]) is a section chief in the science and technology office of Sinopec Yangzi Petrochemical Co. Ltd. in Nanjing, China. He has more than 20 years' professional experience in the petroleum oil refining, petrochemicals and polymer industries. He holds a BS (1987) in applied chemistry from Huazhong University of Science and Technology and an MS (2005) in chemical engineering from Nanjing University of Technology.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com