Midor grassroots refinery completes final milestone of start-up

Successful completion of the refinery observation test run (ROTR) at the Middle East Oil Refining Co. (Midor) plant in Alexandria, Egypt, was the final step in the start-up of the grassroots plant. The ROTR was completed in late August 2002.

Midor, established in the Alexandria Free Zone, is a private oil company that was founded to build the Midor Refinery Complex. Midor successfully completed the project 46 months after the preconceptual stage.

Midor contracted Technip-Coflexip SA to build the 100,000-b/sd refinery as a lump-sum, turnkey project (OGJ, Mar. 19, 2001, p. 66).

The refinery process units started up between January and April 2001. Since startup, the refinery has exceeded the guaranteed production parameters. Final products from different crude blends have met all specifications.

Refinery observation test run

Technip had a contractual obligation to conduct the ROTR after successfully completing individual unit test runs. Individual test runs involved 25 tests of process and utilities units and were completed between June and October 2001.

The final test, however, was the toughest. We conducted the ROTR to verify the overall material balance, final product quality, and utilities consumption while producing high-quality commercial products whose value was in-line with a guaranteed economic gain. The test was difficult because the guaranteed weight recovery was ≥99 wt % and the test duration was 5 days, not the usual 3 days.

Two days before the August 2002 test, the feedstock—a Dubai-Oman crude blend—was lined up to the refinery.

We adjusted the crude distillation unit (CDU) and vacuum distillation unit (VDU) operating parameters to produce the product cuts in-line with design parameters.

Downstream units were lined up to minimize level changes in rundown tanks. Final test tank levels were the same as starting values because we bypassed the intermediate tanks and operated downstream units on hot feed.

We experienced no problems during the ROTR. All process and utility units performed well and without any mechanical or operational problems.

No pumps or compressors tripped. Individual process units yielded products in excess of the guaranteed quality and quantity.

All ROTR process and utility guarantees were met, namely:

- 100% refinery capacity.

- 99.5 wt % saleable products recovery, including fuel gas.

- Saleable products monetary value (3.8% more than what was guaranteed).

- Final product quality.

- Overall refinery utility consumption.

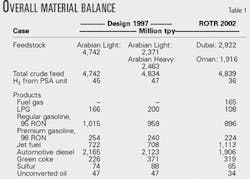

Table 1 shows feedstock and product rates achieved during ROTR on the Dubai-Oman crude blend. Table 1 also summarizes the design feed and product rates for two design cases: Arabian Light crude and a 50/50 blend of Arabian Light and Arabian Heavy crude.

null

null

Product quality

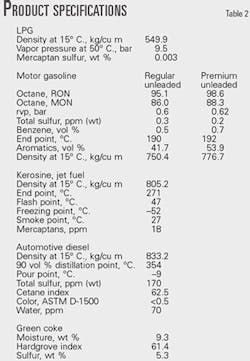

Midor refinery product slate includes LPG, regular and premium motor gasoline, kerosine-jet fuel, automotive diesel, sulfur, and coke. Unconverted oil produced in the hydrocracker (2 wt % on feed) is used as fuel along with refinery-produced fuel gas.

Although the contract was signed in July 1996 with final product specifications at that time, the Midor refinery produces high-quality products in compliance with year 2000 and 2005 European specifications.

The Midor refinery scheme is designed to produce maximum middle distillates. Production levels achieved during the ROTR were:

- Mogas, 23.2 wt % on crude.

- Jet fuel, 23.0 wt %.

- Diesel, 39.4 wt %.

The gasoline pool is 80% of 95 RON regular unleaded and 20% of 98 RON premium unleaded.

Table 2 shows product analytical results recorded during the ROTR. Diesel sulfur originated from two sources: hydrocracker diesel, 3 ppm, and distillate hydrotreater diesel, 248 ppm.

Refinery configuration

The grassroots Midor refinery is in the Alexandria, Egypt, free trade zone on an area of 120 hectares.

It is built on five terraces from 0 m to 40 m elevation.

The refinery is equipped with crude import, products dispatch, and shipping facilities.

Conceptual design outlined the optimal process configuration. We selected hydrocracker and delayed coker technologies to maximize liquid product yield, obtain a high conversion of heavy material into desulfurized gasoline and distillates, and minimize coke yield.

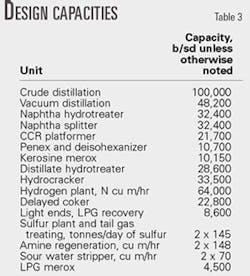

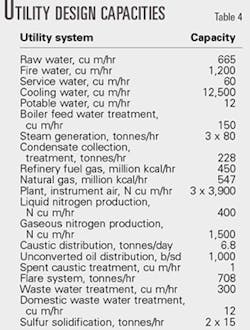

Table 3 summarizes the process units and design capacities. Table 4 lists the utility units and design capacities.

Technip designed the CDU and VDU (Fig. 1), hydrogen production unit, sulfur recovery unit, and other nonlicensed process units, utilities, and off-sites facilities.

UOP LLC was the licensor for eight process units: naphtha hydrotreater, naphtha splitter, continuous catalytic reforming (CCR) Platformer (Fig. 2), Penex unit, distillate Unionfiner, Unicracker, LPG Merox, and kerosine Merox.

Conoco-Bechtel Coker Technology Alliance was the licensor for the delayed coking unit.

Since the initial operations, the refinery has processed many different crude oils including Dubai, Oman, Urals, Arabian Extra Light, Gulf of Suez, Western Desert, and heavy Egyptian crudes.

All the individual unit test runs and overall refinery test run used a 60/40 vol % blend of Dubai and Oman crude oils. The contractor and licensors endorsed or redefined all process guarantees for the new feedstock.

Project execution

The lump-sum turnkey (LSTK) contract between Midor and Technip came into force on July 1, 1997. The timing was risky because the parties signed the LSTK contract before the basic design package was developed.

The 46-month project schedule included basic design, detailed design, procurement, construction, start-up, and operations up to the successful completion of test runs.

Contractors and licensors conducted the basic design simultaneously. Midor and the contractor assigned resident design engineers to the licensors' offices to have full participation and real-time coordination during the design work. This allowed the project to move swiftly to the detailed design phase.

The project directorate in Rome managed the project, which was executed in various operating centers.

Major documents prepared in Rome defined and organized the approach between operating centers. The documents included: project scope, correspondence, homogenization procedure, document approvals, procurement with "umbrella" contracts, accounting procedures, numbering system, engineering execution, cost control, schedule, and reports.

Midor organized and assigned a full project team to the Paris and Rome operating centers to expedite document review and approval.

Mechanical completion during the construction period, which lasted from September 1998 to February 2001, took 29 million man-hr. At its peak, 5,000 people were working on the project.

Start-up, initial operations

Utilities started up between April and October 2000. The first crude oil shipment was completed by the end of October 2000.

The CDU started up in January 2001 on Al Hamra, a Western Desert crude oil. For 2 months the unit operated in recirculation mode; i.e., products were remixed and sent back to crude oil tank.

Near the end of recirculating operations, some products, primarily middle distillates, were pulled out and sold. This made the feedstock a bit heavier and more difficult to process.

The hydrogen generation unit was started up during this period.

Once-through CDU operations began on Mar. 12, 2001, on Basrah Light crude oil. The VDU started up Mar. 14, 2001. Other process units started up sequentially with the isomerization and delayed coker starting up last on Apr. 27. The delayed coker started up on a 42° API Western Desert crude oil.

In the first 5 months of operations, the refinery processed a number of crude oils including light Western Desert, Basrah Light, Gulf of Suez blend, and Urals.

The hydrocracker started up on July 21, 2001.

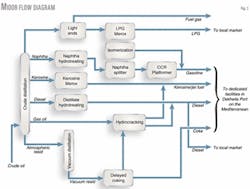

Fig. 3 shows a simplified Midor flow diagram.

Specific design features

The Midor refinery has the flexibility to feed downstream units with either hot or cold feed or a hot-cold mixture in any proportion. Downstream units can receive feed directly from upstream units (hot), from storage tanks (cold), or both simultaneously.

This multiple feed temperature design increased the size of charge heaters, feed-effluent exchangers, product condensers, and charge pumps; but it more than paid for itself in terms of operational flexibility.

Environmental impact

Energy conservation was a main criterion in the refinery design. We applied pinch analysis in all the units to maximize heat recovery. For example, the crude inlet temperature to CDU heater averaged 277° C. during the CDU-VDU test run and the Platformer feed-effluent exchanger had a design hot-end approach of 31° C.

All major refinery heaters were equipped with an air-preheat system and designed with a guaranteed efficiency of 91%. All the heaters had low-NOx burners.

SOx emissions were minimal because the fuel used in the heaters contains little sulfur.

The refinery fuel gas H2S is consistently zero and the sulfur content of unconverted oil, which represents 6% of fuel used, is less than 100 ppm.

SO2 emissions from the sulfur recovery unit are negligible; the unit is designed for 99.9 wt % recovery.

The authors

Arturo Grimaldi is a project director for Technip-Coflexip SA, Rome. He has worked for the company since 1981. As project director, Grimaldi led two grassroots refinery projects with lump-sum turnkey contracts: the Midor project and National Iranian Oil Co.'s 150,000-b/sd Arak, Iran, refinery project. He has a BS (1980) in chemical engineering.

Branko Vukadin is refining technology manager for Technip-Coflexip SA, Rome. He has worked for Technip Italy for the past 13 years as process manager and has experience in conceptual and basic design through start-ups and test runs of major refining lump-sum turnkey projects. Projects include grassroots refineries in Egypt and Iran and FCC complex units in Colombia and Greece. Vukadin has a BSc (1980) in engineering from Belgrade University.