Equipment/Software/Literature

Filtration system aids process plant lube reservoirs

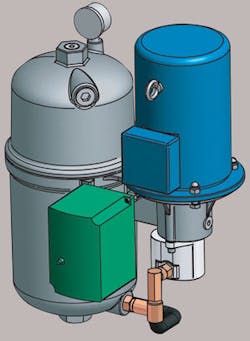

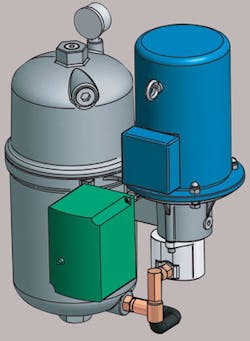

The new VURSA Series of high-performance filtration systems is suited for refinery and petrochemical operations.

Designed to remove particulate matter and water from lubrication oil and hydraulic fluid reservoirs, systems can help extend the life span of bearings and other metal components.

Designed to accommodate a variety of flows, voltages, filtration requirements, and installations, self-contained units employ the maker’s patented pleated filter media technology to remove contaminants. Systems install quickly on the outflow line from lubrication oil reservoirs. Easy to service, these systems can be isolated to facilitate filter changes and routine maintenance, the firm notes.

Systems are powered by 2 hp explosion-protected motors and equipped with 2 gpm or 5 gpm variable speed pumps. Vessels used on the systems have a 150 psi pressure rating and a 22 psi element bypass.

Source: Kaydon Custom Filtration Corp., 1571 Lukken Industrial Drive West, LaGrange, GA 30240.

New unit helps prevent illegal oil discharge at sea

SmartSafe, a new plug-n-play, is a compact unit designed for fail-safe prevention of illegal oil discharge at sea.

The unit monitors and records all aspects of the discharge process in real-time: separator control, oil content output, and flow rate and cumulative flow through the discharge pipe. In this way it can anticipate any illegal discharge and deal with it by shutting off the overboard discharge valve if necessary.

To assist with regulatory compliance, at the end of the discharge process a batch record is printed containing all aspects of the discharge and any errors or inconsistencies that occurred during the process. As much as 2 years of discharge data can be stored and presented.

Data are stored within SmartSafe and can be played back graphically on its built-in screen.

Source: Rivertrace Engineering Ltd., Unit p, Kingsfield Business Centre, Philanthropic Rd., Redhill, Surrey RH1 4DP, UK.