Saudi Aramco installs new LPG recovery unit at Yanbú refinery

Saudi Aramco recently converted its semi-regenerative platformer unit in its Yanbú refinery to a UOP-licensed continuous catalytic regenerative (CCR) process. To recover valuable gases from the CCR net gas, Saudi Aramco installed an LPG-recovery unit that uses a technology unfamiliar to the refiner.

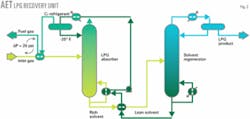

The new unit (Fig. 1) was installed to maximize LPG recovery and increase hydrogen purity of the net gas for use in a new diesel hydrotreater unit.

This article describes how the enhanced absorption process was incorporated at the Yanbú refinery to complement the existing saturate-gas-conditioning unit and shares the experience with the start-up and operations of the LPG-recovery unit.

The recovered, higher-value LPG is separated in an existing debutanizer column. A new three-stage propane refrigeration system is used to chill the CCR net gas to maximize LPG recovery.

Yanbú reformer

The original fixed-bed platformer unit had operated in the Yanbú refinery since 1983. Saudi Aramco elected to revamp the 38,000-b/d UOP fixed-bed platformer into a 40,000-b/d CCR platformer system to:

- Increase unleaded gasoline production by 8,000 b/d.

- Increase refinery-product values by allowing the option of blending light straight-run naphtha and butanes into the gasoline pool.

- Reduce requirements for expensive methyl tertiary butyl ether purchases.

- Improve reliability, safety, and efficiency by reducing unit downtime.

As part of the reforming process, the CCR system produces a net gas that is rich in C3+ LPG and hydrogen. To maximize propane recovery from excess net gas and existing saturated gas debutanizer overhead, Saudi Aramco chose a licensed LPG-recovery system from Advanced Extraction Technologies Inc. (AET) because of its effectiveness in achieving high propane recoveries (96+%) from about 151 psig offgases without requiring feed-gas compression.

This article describes the incorporation of new-to-Saudi Aramco technology and shares the experiences with the AET LPG-recovery unit that started up during June-July 2006.

LPG-recovery technology

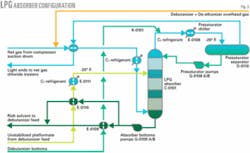

A typical AET LPG-recovery unit (Fig. 2) uses a C5+ solvent for absorbing the C3+ LPG components from a refinery offgas stream. C5+ solvent is used because it has low molecular weight, which reduces solvent circulation, and a low vapor pressure, which reduces solvent loss.

In the AET process, absorption effectiveness is further enhanced when the lean C5+ solvent is presaturated with the “undesired” hydrogen and methane in the inlet refinery offgas (fuel gas). This is available at the LPG absorber overhead because the propane and butanes are removed from the offgas inlet gas in the absorber column.

The presaturated solvent at about 25° F., separated from the fuel gas, is pumped to the top of the absorber. This hydrogen-methane presaturated solvent, upon entering the absorber, absorbs only the propane and butanes.

The LPG absorber is reboiled to ensure that recovered C3+ LPG meets the specification content for all light ends in the inlet refinery offgas. Rich solvent from the LPG absorber bottom is fractionated in the solvent regenerator to separate absorbed C3-C4 LPG as an overhead product and a C5+ lean solvent as the bottoms. The solvent regenerator operation is similar to that of a debutanizer column. Any new AET process facility therefore requires an LPG absorber column and a debutanizer-regenerator column.

LPG recovery at Yanbú

Because the refinery already had a debutanizer column as part of its saturated gas concentration unit, Saudi Aramco considered alternatives to eliminate the need for a new debutanizer column just for the new LPG absorber.

Instead of securing a new segregated C5+ stream as the lean solvent, Saudi Aramco considered stabilized platformate, which is a C5+ product available from the existing debutanizer column, as the preferred lean solvent. Unfortunately, the required solvent circulation rate of stabilized platformate as lean solvent was large enough to require a larger-diameter debutanizer column.

In order to use the existing debutanizer column, some of the unstabilized platformate feed to the debutanizer was redirected to the new LPG absorber to absorb some of the LPG from the CCR net gases.

Circulating some of the stabilized platformate from the bottom of the existing debutanizer as lean solvent for the LPG unit absorbed the remaining LPG in the CCR gases. This essentially split the total C5+ solvent requirement for the desired high-propane recovery. We solved the problem of using unstabilized platformate feed, which is essentially saturated with propane and butanes, as a bulk solvent for part of LPG absorption by chilling the unstabilized platformate to a significantly lower temperature of 20° F.

Fig. 3 shows the LPG absorber configuration.

To minimize platformate loss from the absorber overhead and to increase LPG absorption efficiency, the stabilized platformate solvent stream is presaturated with hydrogen, methane, and ethane. It is mixed with overhead gases from the LPG absorber and chilled to about -20° F. Chilled gases are separated from the chilled solvent stream in a pre-saturation separator. The pre-saturated lean solvent is pumped to the top of the LPG absorber column.

Unstabilized (bulk solvent) and stabilized debutanizer bottoms (lean solvent) platformate streams are precooled with a cold stream from the absorber bottoms stream and then chilled with propane refrigerant to -20° F. CCR net gas combines with the recycled overhead gases from the debutanizer and de-ethanizer to form the combined feed to the LPG absorber.

The combined gas stream is precooled with cold energy from propane free, light-end gases and then chilled to 20° F. before entering the LPG absorber near the bottom. The upward-flowing chilled gases counter-currently contact the downward-flowing presaturated lean solvent, which absorbs C3+ components. Cold, rich solvent from the LPG absorber bottom is pumped and warmed against the unstabilized and stabilized platformate solvent streams. It then joins the unstabilized platformate feed stream to the existing debutanizer downstream of the take-off point for the unstabilized solvent.

Comparing Figs. 2 and 3 shows that the LPG absorber at Yanbú does not have a reboiler. The simpler absorber design takes advantage of a de-ethanizer in the saturated gas concentration unit, which takes feed from the debutanizer overhead to meet the ethane specification of the C3-C4 product.

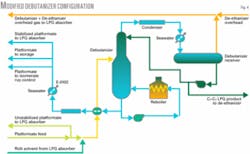

Fig. 4 shows that, at the debutanizer overhead, uncondensed light-ends are separated from the condensable C3-C4 mixture. Overhead liquid C3-C4 product is further fractionated in a de-ethanizer and depropanizer, which produce C3 and mixed C4 products.

Separated light ends from the debutanizer overhead, along with the separated ethane and lighter from the overhead of de-ethanizer, are recycled back to the LPG absorber to recover any C3+ hydrocarbons.

To handle increased processing load in the existing debutanizer, modifications to existing equipment included:

- Addition of series heat-transfer surface to the feed-bottoms exchanger.

- Addition of parallel heat-transfer surface to the bottoms product seawater cooler.

- Addition of a new overhead seawater trim condenser.

- Replacement of overhead product and reflux pump.

Feed pumps were replaced in the existing de-ethanizer system. In the depropanizer system, the overhead air-cooled condenser was replaced with a seawater shell-and-tube condenser and the overhead net propane product cooler was replaced with a larger heat exchanger.

Propane refrigeration cycle

To provide the required chilling, a propane refrigeration system was required.

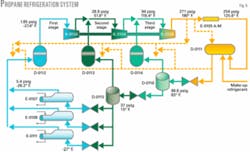

Fig. 5 shows the closed loop, three-stage propane refrigeration cycle, which provided the necessary chilling for the unstabilized and stabilized platformate solvent streams and CCR net gas feed to the LPG absorber.

All of the three process services-the feed gas chiller E-0107, platformate chiller E-0111, and presaturation chiller E-0108-cool the respective process streams to about 20° F. using 27° F. propane refrigerant. Vaporized propane from the chillers enters propane compressor K-0104 through the first-stage suction drum D-0112.

The low-pressure economizer D-0115 and high-pressure economizer D-0116 reduce the refrigerant compressor horsepower by separating the second-stage side load flashed vapors at 15° F. and third-stage side load flashed vapors at 63° F., respectively. Compressed propane refrigerant vapors are condensed in the air-cooled condenser E-0105 and returned to the propane accumulator D-0111.

The dotted line in Fig. 5 shows that the refrigerant compressor’s antisurge system controls the flow of hot discharge propane and quench liquid propane to the first, second, and third-stage suction drums, D-0112, D-0113, and D-0114, respectively.

Overall design performance

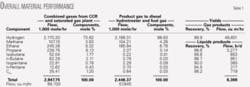

Because the LPG absorber was integrated with the debutanizer, de-ethanizer, and depropanizer in the saturated gas concentration unit, it is quite cumbersome to ascertain the material recovery performance of the LPG absorber system. By drawing an envelope around the integrated system, we determined LPG recovery by analyzing the two gas streams (Table 1).

null

Precommissioning activities

The unit was constructed as part of a platformer revamp project. When the mechanical construction was completed, Saudi Aramco had performed these precommissioning activities:

- 120 hydrotests were done.

- 280 instrumentation loops were checked.

- Eight refrigeration loops were chemically cleaned.

- Propane compressor lube oil system was flushed.

- 31 pieces of equipment were boxed up.

- 22 motors were unclipped and run for 4 hr.

- The instrumentation connections were completed and reinstated.

After completion of the precommissioning activities, additional start-up precommissioning activities included purging, evacuating, and drying out the refrigerant and lube-oil circulation system with nitrogen to a 40° F. dewpoint; purging and drying out the absorber system with nitrogen to a 40° F. dewpoint; stroking and functionally testing all control valves; commissioning all pressure isolation valves; filling the refrigeration loop with propane and collecting samples to confirm that the system dewpoint was <-40° F.

LPG-recovery process start-up

After completing all the commissioning activities and with the debutanizer producing a C5+ platformate product meeting the C4 and lighter content specification, we determined that the available initial CCR net gas flow on June 18, 2006, was about 29.6 MMscfd. First, therefore, we initiated the flow of unstabilized platformate (bulk solvent) from the feed to the debutanizer at about 167 gpm.

Once the level in the bottom of the LPG absorber C-0101 was established at about 60% level transmitter (LT) range, we started the absorber bottoms pump G-109B to circulate bulk solvent through the two solvent cross-exchangers back to the debutanizer column feed.

After about an hour of established circulation for the bulk solvent, we initiated flow of the debutanizer bottoms (lean solvent) stream at about 150 gpm. After filling the piping and exchangers, the lean solvent level began to increase in the presaturation separator D-0110.

When the level was established at about 60% of the LT range, we started the presaturation pump G-0108A to transfer solvent to the absorber column’s top. Within 20 min of starting G-0108A, level in the absorber bottom started to increase, which indicated that the two solvent circulation loops were completed. The LT controlling flow from the discharge of the absorber bottoms pump G-0109B was switched to auto control.

With no gas flow through the absorber system, and after establishing lean solvent circulation, the column pressure started to decrease to about 122 psig from an initial pressure of about 142 psig. This indicated slight absorption of hydrocarbons even at warm solvent temperatures (98° F.).

To reestablish the pressure in the column to the CCR net gas compressor-suction drum pressure without flowing gas through the LPG-recovery unit, we reopened the inlet isolation valve. The isolation valve blocking flow from the LPG absorber overhead to the fuel-gas system remained closed. With the circulating warm solvent, the pressure increased and stabilized at about 139 psig.

When establishing the aforementioned two solvent circulation circuits, we identified several level and flow instrumentation calibration issues:

- First circuit. Between the debutanizer feed, cross-exchanger E-0110, platformate chiller E-0111, LPG absorber C-0101, absorber bottoms pump G-0109B, cross-exchangers E-0110 and E-0109, and debutanizer feed.

- Second circuit. Cool debutanizer bottoms from E-0102, cross-exchanger E-0109, mixer K-0101, presaturation chiller E-0108, presaturation separator D-0110, presaturation pump G-0108A, LPG absorber C-0101, absorber bottoms pump G-0109B, cross-exchangers E-0110 and E-0109, debutanizer feed

Before attempting to start the propane refrigeration system, we fixed all the instrumentation calibration issues during the next 24 hr. We subsequently initiated the flow of CCR net gas through the LPG-recovery process by opening the isolation valve at the outlet of the absorption system and closing the bypass isolation valve around the LPG-recovery unit.

Propane refrigeration start-up

With the established cooling load through the tube side of three chillers, we could start up the refrigeration system. Unfamiliarity of the refrigeration cycle within the refining industry as a whole was a significant obstacle for the operations team in developing the feel for starting and controlling a three stage, closed-loop propane refrigeration system.

Table 2 summarizes the 12 compressor trips and respective lessons learned that eventually resulted in a successful start-up of the three-stage centrifugal compressor and closed loop refrigeration cycle.

Although comparable quench-based suction drum configurations are quite extensively used at Saudi Aramco’s gas processing facilities, a recurring problem in the start-up at Yanbú was managing and controlling liquid levels in the various suction drums.

The hydrocarbon processing industry uses large refrigeration systems without needing to add quench liquid into the compressor suction drums by simply routing the antisurge hot gas from the compressor discharge through a sparger line below the tube bundle in kettle chillers and in economizer drums where liquid refrigerant is normally present. This avoids the potential imbalance between the antisurge gas flows and quench-liquid temperature control valves, and also ensures that the compressor suction drums remain dry, which prevents compressor trips from high liquid level. This type of system at the Yanbú refinery would have simplified significantly the start-up of the refrigerant compressor.

When attempting to start up the compressor, we emphasized starting flow of refrigerant vapors as quickly as possible into the refrigerant compressor to keep the discharge temperature within limits and trying to close the antisurge gas and liquid quench flows to reduce overloading the compressor motor.

We realized after the twelfth trip that the inlet feed gas from the CCR unit was only about a third of the design gas flow. Also, an analysis of the compressor surge flows revealed that as long as the inlet gas flow from the CCR unit was less than 88% of the design flow for the LPG-recovery unit, the installed refrigeration compressor will always have its antisurge valve open.

This allowed us to change the start-up focus from trying to close the antisurge valve to managing the introduction of available refrigerant vapors generated from the process streams through the chillers. This was the final factor that led to the successful start-up of the refrigeration system. Within about 5 hr of continued integrated operation of the process-refrigeration systems, all temperatures reached their expected settings.

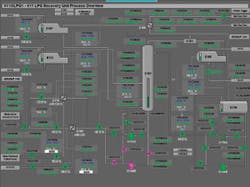

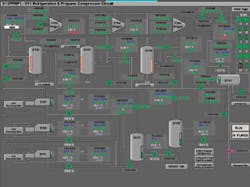

Fig. 6 shows a representative DCS display snapshot of the process flow. Fig. 7 shows a display snapshot of the refrigeration system.

Further operations

Operation of the integrated LPG-recovery facility is easy, stable, and flexible to gas flow and composition changes. If the refrigeration compressor accidentally trips, the LPG-recovery process can continue to operate stably and await restart of the refrigeration compressor.

Operation of the Yanbú refinery unit has successfully demonstrated turndown to 30% of the design inlet gas flow capacity. With this start-up, Yanbú refinery has successfully pioneered the incorporation of colder temperatures within a refining environment to maximize recovery of value from its hydrocarbon resources.

The unit has operated continuously and smoothly since starting up in July 2006.

The authors

Saleh M. Al-Shahrani ([email protected]) is lead process engineer for the new CCR platformer and isomerization PENEX units at Saudi Aramco’s Yanbú refinery. He has more than 9 years’ experience in the operations engineering unit at the Yanbú refinery. Al-Shahrani holds a BS in chemical engineering from King Fahd University of Petroleum & Minerals, Saudi Arabia.

Yuv R. Mehra ([email protected]) is a process engineering consultant in the process and control systems department for Saudi Aramco, Dhahran. He joined Saudi Aramco in 2000. He has more than 34 years of practical process engineering experience related to processing of natural gas, refining, and petrochemicals. Mehra holds an MS in chemical engineering from UCLA.