Offshore processing plant uses membranes for CO2 removal

The Cakerawala production platform (Figs. 1 and 2), an offshore processing facility in Block A18 of the Malaysia Thailand Joint Development Area in the Gulf of Thailand, installed semipermeable membranes to lower the CO2 content in its produced gas.

The CO2-removal process on the Cakerawala production platform (CKP) uses Cynara semipermeable membranes. The facility was successfully commissioned in December 2004 and is currently continuing to operate.

CKP gas treating

Carigali Hess Operating Co. Sdn. Bhd., a joint venture of Petronas Carigali Ltd. and Hess Oil Co. of Thailand Ltd., operates the plant, 150 km offshore (Fig. 3), for the Malaysia-Thai Joint Authority.

Raw untreated inlet gas to CKP with about 37% CO2 has a sales-gas specification of less than 23% CO2 before being delivered to the buyer’s pipeline.

The low-CO2 sales gas produced is compressed and routed to southern Thailand in a 34-in. subsea 270-km pipeline, owned and operated by Trans-Thai Malaysia on behalf of the gas buyers. There, the gas is used primarily for power generation and chemical industries in Thailand and Malaysia.

Due to a delay in the onshore gas processing plant, a new specification of 10% CO2 was needed, with an operating specification of 8% to provide an adequate operating margin. Even though initial operating requirements of 8% CO2 sales gas were significantly different from the design conditions of 15-23% CO2, the membrane system was adaptable to the new design condition and allowed Carigali Hess to operate to this markedly different specification.

The flexibility of the installed Cynara membrane system allowed Carigali Hess to begin gas production about 8-9 months earlier than would have been otherwise possible.

Design

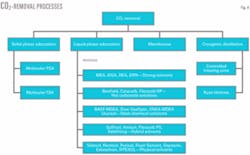

During conceptual design, the project developers evaluated different processes for gas separation for use at CKP. Those processes included CO2 membranes, pressure swing adsorption, amines, and cryogenic distillation (Ryan Holmes process). Fig. 4 shows the different types of processes.

In 1999, CO2 membranes were selected instead of other technologies for CKP due to environmental considerations and space and weight savings.

A technical and commercial evaluation was then conducted of different CO2 membrane suppliers. In 1999, a contract was awarded to NATCO to design and build the required membrane system for CKP Phase 1. In addition to the membrane CO2-removal system, the scope of supply included the gas pretreatment system, dehydration, cooling, and liquids separation for condensate recovery.

To assist with design specifications NATCO launched a pilot operation in Snyder, Tex. This pilot operation was used to help better identify exact design considerations and was developed with nearly identical operating conditions to those expected for CKP operation.

CKP membrane description

The design condition of the membrane plant was to deliver 425 MMscfd of sales gas containing 15% CO2 from a feed-gas volume of 700 MMscfd and feed CO2 concentration of about 37%. Design pressure to the membranes is 630 psig (43.4 barg).

The sales-gas agreement called for the CO2 content in the sales gas to be less than 23%; for design purposes, however, 15% was chosen as the design point. This enabled Carigali Hess to take advantage of higher heating value at the lower CO2 condition, which translates to more revenue at the same export volumes.

Designing for 15% also provided considerable operating margin and, therefore, increased operating flexibility.

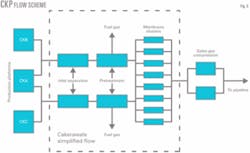

The membrane CO2-removal system consists of two 50% gas-pretreatment trains. This conditions the raw well-stream gas before it enters the membranes clusters (Fig. 5).

Each train consists of inlet cooling, dehydration that uses desiccant beds (silica gel), dry-gas filters, and gas chilling with mechanical refrigeration (propane as refrigerant). Energy recovery from the cold membrane streams through a series of heat exchangers and a closed-loop chilled water system minimizes the refrigeration duty.

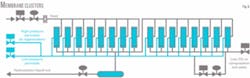

The membrane clusters themselves consist of four separate subtrains in each 50% pretreatment train (eight clusters in total) all operating in parallel.

Each cluster operates as a two stage, CO2-removal process (eight elements in each stage), with the low CO2 nonpermeate product stream from the first stage routed as feed gas to a second stage.

Fig. 6 shows a simplified schematic of a membrane cluster.

Each cluster therefore contains 16 total membrane elements each housed in individual enclosures (Fig. 7). The membrane elements are 16-in. diameter.

The nonpermeate from the second stage (at about 15% CO2) feeds the sales-gas compressors where it is compressed, metered, and delivered to the pipeline for transport onshore.

The combined low pressure, high-CO2 permeate streams from all membrane clusters are routed to flare. Permeate streams from each individual cluster can be delivered to either the low-pressure permeate header that goes directly to flare or to a higher-pressure permeate header where it is used for regeneration gas in the pretreatment dehydration system and then delivered to the same flare as the low-pressure permeate.

The difference in permeate pressure between the low-pressure permeate and high-pressure permeate is about 30 psig (2 barg), with actual pressures of 25 psig and 55 psig, respectively.

The higher permeate pressure reduces membrane selectivity and capacity so that only the minimum quantity of clusters that will furnish the required regeneration gas flow rate are placed in the higher permeate pressure operation. Other clusters remain in low permeate pressure operation to maximize selectivity and overall capacity. Each cluster can be automatically controlled to deliver the cluster permeate to either the low-permeate-pressure system or the higher permeate pressure system.

The Cynara membranes at CKP were designed to operate with a low feed-gas temperature (-7° C.) and without superheat. Gas entering the membrane clusters is at its hydrocarbon dewpoint and hydrocarbon condensation occurs as CO2 is removed from the gas stream.

The system was designed with vertical membranes in which the formed hydrocarbon liquid can easily be drained away from the membranes. The process of CO2 removal also results in a significant temperature reduction across the membranes and affects all of the streams separated in the membrane system.

This cooling effect of the membrane-processed streams is used to reduce refrigeration loading in the pretreatment section. Each of these cooled product streams is optimized in the pretreatment section with cross exchangers-product is on one side and a water-glycol mix is on the other.

This water-glycol loop is a closed loop chilled-water system, which reduces process gas temperature upstream of the mechanical refrigeration system, thereby significantly reducing refrigeration duty.

Initial operations

The design basis of the membrane system was to deliver less than 15% CO2 in the sales gas to the pipeline. A delay in construction of an onshore gas processing plant led to the signing of an interim sales-gas agreement for the initial operations.

This agreement called for a reduced sales-gas flow rate of 200 MMscfd, with less than 10% CO2 content. This meant that gas produced on the platform would bypass the onshore gas plant and feed directly into the onshore gas grid.

The CKP facility, therefore, had to be commissioned and proven to a much stricter sales-gas specification than that for which it was originally designed.

NATCO simulated the new design parameters to determine the effects of operating at this new CO2 level, not only on the actual membrane performance, but also the supporting utilities, especially the chilled-water loop.

To ensure an adequate operating margin below the new 10% CO2 spec, operating at 8% CO2 was required. The simulations showed that a product sales-gas rate of 280 MMscfd could be achieved with all eight clusters online (128 membranes) at the required 8% product specification.

Only six clusters were therefore required to be online initially to meet the required 200 MMscfd sales-gas rate at 8% CO2, thus providing sufficient sparing of membrane capacity.

The membrane system commissioning was performed in conjunction with the total platform start-up. Commissioning and start-up of the membrane system consisted of:

- Pretreatment, start-up, and initial regeneration of all four dehydration beds on each train.

- Purging of each membrane cluster (empty) at a sufficient rate to flush any foreign matter.

- Start-up of one membrane cluster with the 16 service elements to prove anticipated performance at the lower CO2 case and to tune all control parameters.

- Final sales-gas production into the pipeline.

Start-up activities commenced in early November 2004, with commissioning of the first CO2 pretreatment train soon thereafter.

Cluster commissioning began in late November 2004 and continued through December 2004. After the commissioning of each cluster, the 16 actual service membrane elements were prepared and installed.

On Dec. 11, 2004, the first cluster was started up with 16 new service elements to provide an indication of anticipated performance at the lower CO2 case. Feed gas was introduced at the rate that had been anticipated for a fully loaded cluster to produce 8% CO2 product.

Also, as a result of information gathered from pilot testing and supporting information from lab research and other operating facilities, NATCO recommended a slightly warmer membrane feed temperature of 2° C.

This warmer temperature would result in nearly identical separation and permeability characteristics; but over the long term, this would extend membrane lifetime and performance.

At this off-design condition, the initial performance result matched the performance that NATCO expected based on 2001 in the pilot plant. The results showed that the initial performance was better than expected (for the less than 10% CO2 operating case), particularly in terms of separation, with lower-than-expected hydrocarbon losses. The required feed rate was only about 1.4 times the nonpermeate rate, compared with an expected factor of about 1.65. This indicated the vent losses were lower than expected during initial operation.

During this interim period, however, the membrane performance was lower than anticipated. There were several factors that contributed to this:

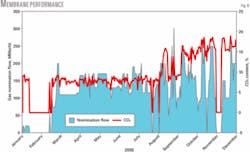

- Widely varying inlet gas flow rates due to rapidly changing sales-gas nomination flow rates (Fig. 8). Membranes prefer stable operations. Regular start-ups and shutdowns will accelerate declines in performance.

- Colder than original design feed gas temperatures of -7° C. and moving further away from recommended temperature of 2° C. There were some turndown issues with the refrigeration system. At lower flow rates, it was difficult to control the system at the warmer temperatures required.

- Less CO2 in the sales gas requires lower temperatures across the membrane system due to the required higher percentages of feed gas that must be permeated.

Current operations

During second-half 2005, the onshore gas processing plant was commissioned. This allowed CKP operations to revert to the original design condition; sales gas had 15-18% CO2. Additionally, the flow conditions became much more stable with fewer shutdowns and the problems with chiller temperature control were resolved.

Carigali Hess was therefore comfortable in changing out the original membranes. New membranes were installed to improve system performance. Membranes were replaced on a cluster basis (16 at a time) beginning in November 2005, about 11 months after initial start-up. The last cluster received new membranes in August 2006, roughly 20 months after start-up.

When the membranes were replaced, plant performance improved. Membrane feed-gas temperature has stabilized above -1° C. and continues to operate at predicted levels on a regular basis (Fig. 9).

Carigali Hess can only determine cluster-based operating conditions when clusters are operating in the high-pressure permeate mode. When the cluster is in the low-pressure permeate mode, the permeate gas pressure at that specific cluster is insufficient for delivery and analysis by the online gas chromatograph.

Only about one third of the clusters will operate in high-pressure permeate mode; the rest will operate in low-pressure mode. Membranes perform better in low-pressure mode due to the lower backpressure. Measured performance characteristics of the overall plant are therefore better than what has been measured on clusters operating exclusively in the high-pressure permeate mode.

Fig. 10 shows measured membrane performance from a cluster that was loaded with new membranes in December 2005. The data show very little performance declines.

Performance monitoring

Carigali Hess has recently hired NATCO to assist with performance monitoring and measurement of the operating clusters and overall system. This will provide the ability to indicate potential unexpected membrane performance issues or operational anomalies that can be extracted from the measured operating parameters.

The effort to track system performance began in second-quarter 2006 and includes raw data transmitted to NATCO for measuring key performance characteristics. These key characteristics monitored over time will enable NATCO and Carigali Hess to determine performance curves.

These curves can be used for other decisions such as projections for potential membrane use, membrane budget considerations, as well as identifying operating anomalies that may have contributed to reductions in measured performance characteristics.

Also included in this tracking of system performance is an application program residing on a server that Carigali Hess accesses via a secure link through the internet.

This program was developed specifically for CKP and will take current measured performance of the overall plant or on a cluster basis and converge on a solution that matches current measured conditions. These solutions, based on current measured operations, will allow Carigali Hess to better manage its day-to-day operations, including decisions about when it is economical to replace membranes, evaluate which clusters should be in service, determine effects of changing feed gas conditions, impact of surface area vs. sales gas btu content, etc.

Carigali Hess is currently in the process of doubling capacity of the CKP facility to 870 MMscfd from 425 MMscfd of sales gas. NATCO is providing the additional pretreatment equipment and the CO2 membranes for this expansion.

The authors

Alan Callison is the general manager of Cynara membrane service and operations for NATCO Group Inc., Houston. He was previously the international services manager for NATCO and an operations and field services manager for Cynara. Before joining NATCO, Callison was a senior production superintendent with Houston Natural Gas Co.

Graham Davidson is currently head of process engineering for Carigali Hess Operating Co., Kuala Lumpur. He has more than 18 years’ experience as a lead process engineer in the operation, design, commissioning, and start-up of offshore oil and gas plants and onshore petrochemical plants. For the past 8 years, he has been involved in the design, commissioning, and operation of CO2 membranes on offshore gas-processing facilities. Davidson holds a degree (1988) in chemical engineering from Monash University, Australia.