Asphaltene-removal technolgy yields eco-friendly refinery by-products

Warren Chung

Well Resources Inc.

Calgary

Xuebing Li

Pei Yu

Mengtao Cui

Keng H. Chung

Chinese Academy of Sciences

Qingdao, China

Quan Shi

Zhiming Xu

Suoqi Zhao

Chunming Xu

China University of Petroleum

Beijing

Novel noncombustion asphaltene uses are enabling refiners to use materials previously considered waste streams in a manner that has a positive environmental impact.

Ongoing advances in selective extraction of asphaltenes (SELEX-Asp) technology—a solvent-based physical separation process that selectively removes asphaltenes as dry granulates in heavy crude oils and petroleum residue—continue to provide refiners with a cost-effective and flexible solution for realizing maximum value from a refinery’s existing bottom-of-the-barrel streams.

Using asphaltenes for noncombustible purposes serves as a better way to fully use residue in petroleum refining processes, provides a carbon-storage option for the industry, and offers an important step towards global decarbonization efforts. Further, production of solid asphaltenes can be done at relatively reduced costs and in industrial quantities, which addresses the key hurdle related to traditional remediation of contaminated water and soil.

This article describes a low-cost solution for simplifying and adding flexibility to refinery operations while simultaneously producing by-products that have environmental benefits.

Background

Product-slate optimization is a key consideration for refiners when implementing operating configurations. Equally important to a refiner’s bottom line is minimization of petroleum waste streams, which require handling and disposal at the refiner’s expense. This is particularly relevant for operators that process heavy and ultraheavy crudes, as heavier feedstocks contain disproportionately large volumes of asphaltenes and other contaminant-rich residua subfractions (OGJ, Jan. 20, 1997, p. 66).

Environmental stewardship and strict adherence to constantly evolving regulatory protocols are also major considerations. Global consumer concern over pollutants, contaminants, and emissions like heavy metals, sulfur, and carbon dioxide are driving policy makers to implement new standards that may further restrict a refiner’s ability to conduct its operations and deal with petroleum by-products.

Refinery asphaltene management

Canadian-sourced Athabasca oilsands bitumen can contain asphaltene exceeding 15% by weight.1

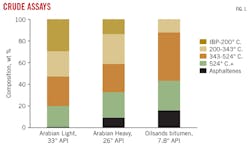

Fig. 1 shows assay comparisons of various crudes from Saudi Arabia and Canadian oilsands with increasing residua contents and decreasing API gravities.

Comprised of up to 85% carbon, asphaltenes are the only refractory oil constituent to refinery processing. Asphaltenes in crude feedstocks during refining are widely known to cause equipment fouling and rapid catalyst deactivation and are considered economically unviable for turning into clean transportation fuels.

Conventional refining and upgrading technologies include two strategies for dealing with asphaltenes: hydrogen addition and carbon rejection.

Refiners use hydrogen addition to transform a fraction of asphaltenes into smaller and more manageable molecules, but such processes are expensive and energy intensive. Carbon rejection entails removal of heavy petroleum subfractions and includes asphaltene removal under high energy-intensiveness thermal separation into petroleum coke.

Petroleum coke has been used as a solid fuel substitute for power generation or feedstock for metal alloy production. Increasingly stringent environmental regulations, however, are reducing the number of outlets for petroleum coke, as users opt to burn lower carbon-intensity fuels such as natural gas. Due to its abundance, petroleum coke is often stockpiled or disposed of at a cost to the refiner.

Conventional solvent-based or slurry phase separation processes produce highly viscous liquid or pitch by-products that require secondary treatment or specialized disposal. Liquid pitch by-products may be subjected to air blowing to produce asphalt blending stock, but the already saturated market for this product limits refiners’ opportunity for profit.

Advances in residua processing

The SELEX-Asp process (Fig. 2) has emerged as a low-cost, low energy-intensiveness option for simplifying bottom-of-the-barrel processing (Fig. 3) by maximizing yield of deasphalted oil suitable for conventional packed-bed hydroprocessing (OGJ, June 6, 2016, p. 70; Apr. 5, 2010, p. 52).

SELEX-Asp is a supercritical solvent-based physical separation process capable of uniquely and selectively removing asphaltenes as dry granules from heavy crudes and petroleum residue (Fig. 4). The dry asphaltene granules are safe and easy to handle.

To date, five commercial SELEX-Asp units with a combined processing capacity of 36,500 b/d have been built in the Asia Pacific, the largest of which has a 20,000 b/d capacity.

Unique properties of granular asphaltene by-products derived from SELEX-Asp technology are providing refiners novel noncombustion uses for petroleum asphaltenes and various asphaltene-derived products (Fig. 4).

Operators use the technology to transform residues and FCC slurry oils into a variety of products, including hydrotreating feedstock for production of low-sulfur fuels compliant with upcoming International Maritime Organization (IMO) 2020 regulations, solid asphaltene granules, asphalt blending stocks, and needle coke.2

A step further

Since its development a century ago and implementation during World War II, the coal-to-liquid process has been modified for vacuum residua applications, commonly referred to as ebullated-bed and slurry-bed hydroprocessing. These hydroprocessing technologies are capital intensive and complex to operate. While complete conversion of asphaltenes into transportation fuels is technically possible, it is not economically viable, partly because of the thermodynamics of the asphaltene conversion process.

Entropy of phase transformation of a substance is an extremely energy-intensive process. As asphaltenes occur as suspended solids in petroleum, it is therefore inevitable that asphaltene conversion requires severe process conditions. In view of increasingly stringent environmental regulations and low crude prices, it becomes economically advantageous not to convert asphaltenes into transportation fuels.

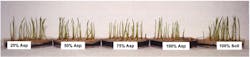

By-products derived from asphaltenes have successfully been used as planting soil (Fig. 5).

Noncombustion uses

Well Resources has developed novel noncombustion uses of petroleum asphaltenes and various asphaltene-derived products such as carbon fibers, mats, and fillers (Fig. 4).3 The new uses are based on the discovery of unique properties of the granular asphaltene by-product yielded by SELEX-Asp technology.

The following example based on samples from operating SELEX-Asp units illustrates an asphaltene application.

Asphaltene properties. Asphaltene grain size commonly ranges from 100-200 μm, although SELEX-Asp process conditions can be modified to produce other sizes.4 The bulk density of granular asphaltenes ranges from 100-200 kg/cu m, while the softening point is about 170° C.

Chemical analyses have shown that solid asphaltenes are nonreactive and pose no biological health risks. Data derived from leachability studies have demonstrated that asphaltenes are virtually nonleachable under moderate to extreme conditions; leachate contaminant contents tested well below the allowable regulatory limits specified by the US Environmental Protection Agency.3

Water, soil treating. Solid asphaltenes are non-hazardous, have an affinity to adsorb organic contaminants, and are compatible with soil as a planting matrix, making them appropriate for the treatment and mitigation of environmental damage caused by contaminants in water and soil.

Traditional water and soil contamination treatments are costly and often inefficient. Many solutions, while having some degree of effectiveness, also have drawbacks.

Well Resources conducted laboratory tests to determine the adsorption of dissolved organic matters (DOM) in various agriculture-derived waste waters by granular asphaltenes. Total organic carbon content of agriculture-derived waste water filtrate was analyzed before and after contact with granular asphaltenes. The study showed that asphaltenes could adsorb up to 60% DOM from waste and drainage water.

Asphaltene-soil compatibility testing for agricultural application also was conducted, in which granular asphaltenes were blended with soil samples in various compositions (0-100 wt % asphaltenes) and used as planting-soil matrices. Planting was conducting under ambient environment conditions (Fig. 5).

In the case of agricultural soil remediation, harmful chemicals may be introduced to treat other more harmful chemicals. For water decontamination, one solution entails contacting with granular activated carbon, which has a large surface area (500-2000 sq m/g) and is therefore well-suited for adsorbing dissolved organics. Such material, however, is costly and involves energy-intensive processes for its production.

Economic factors are the major hurdle for widespread implementation of traditional soil and water-remediation solutions. Solid-asphaltene production and water and soil-remediation efforts are complementary in that the materials can be produced at low cost in required industrial quantities.

Path ahead

In collaboration with the Chinese Academy of Sciences, Well Resources has entered discussions with a municipality in Southern China to use asphaltenes to remediate a nearby body of water. The upcoming project is among six major river decontamination demonstrations planned for the country.

References

1. Chung, K.H., Xu, Z., Sun, X., Zhao, S., and Xu, C., “Selective asphaltene removal from heavy oil,” PTQ, Fourth Quarter 2006, p. 99.

2. Zhao, R., Chung, W., Tang, Z., Yuan, B., Xu, Z., Zhao, S., and Chung, K.H., “Increasing resid processing flexibility,” PTQ, Third Quarter 2018, pp. 37-40.

3. Chung, W., Li, X., Yu, P., Cui, M., Shi, Q., Xu, Z., Zhao, S., Xu, C. and Chung, K.H., “Adsorption Material and Method for Treating Pollutants,” Chinese Patent Application 201910136662.4, US Patent Application 16/293,797, Feb. 25, 2019. Canadian patent pending.

4. Zhao, S., Xu, C., and Wang, R., “Production of de-asphalted oil and fine asphalt particles by supercritical extraction,” Chinese Journal of Chemical Engineering, Vol. 11, No. 6, pp. 691-695, December 2003.

The authors

Warren Chung ([email protected]) is president of Well Resources Inc., Calgary, where he specializes in technology development and assessment, project implementation and integration, and process licensing. Chung developed the best practice protocols for the SELEX-Asp technology and is a coinventor of noncombustible uses for asphaltenes. He holds a BS (2012) with distinction in chemical and biomedical engineering from the University of Alberta. He is a registered professional engineer in Alberta, Canada.

Xuebing Li ([email protected]) is a professor and leader of the heterogeneous catalytic conversion group at the Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences. His research includes high-performance zeolite catalysis, high value-added fine chemicals, bioenergy, functional materials, and environmental catalysis. He is a coinventor of the noncombustible uses for asphaltenes. Li holds a BS (1995) and MS (1998) in physical chemistry from Tsinghua University, China, and a PhD (2004) in industrial catalysis from TU München, Germany. He was a post-doctoral fellow at University of California at Berkeley and employed as a senior scientist at TU München.

Pei Yu ([email protected]) is a post-doctoral fellow at the Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences. Her research interests include ammonia decomposition, lignin depolymerization, and wastewater treatment. She is a coinventor of the noncombustible uses for asphaltenes. Yu holds a BS (2010) in chemistry from Nankai University, China, and a PhD (2016) in physical chemistry from the Dalian Institute of Chemical Physics, Chinese Academy of Sciences.

Mengtao Cui ([email protected]) is a visiting student at the Chinese Academy of Sciences and enrolling in BS program in chemical engineering at Changzhou University. He is involved in laboratory studies related to bioenergy and synthesis, and a coinventor of the noncombustible uses of asphaltenes.

Keng H. Chung ([email protected]) is a research program advisor for Chinese Academy of Sciences and an energy consultant for investment bankers. He also acts as a process troubleshooting expert for petroleum operations and is actively involved in developing sustainable energy technologies. He is a coinventor of the SELEX-Asp technology and noncombustible uses for asphaltenes. Chung holds a BS (1982) and MS (1984) in chemical engineering from Queen’s University in Ontario, Canada, and a PhD (1988) in chemical and petroleum engineering from the University of Calgary. He is a registered professional engineer in Alberta.

Quan Shi ([email protected]) is a professor at China University of Petroleum, Beijing, and a deputy director at China State Key Laboratory of Heavy Oil Processing. Shi is specialized in analytical chemistry and petroleomics. He is a coinventor of the noncombustible uses for asphaltenes. Shi holds a BS (1995) and MS (2004) in chemical engineering from China University of Petroleum and a PhD (2008) in geological chemistry from China University of Geology.

Zhiming Xu ([email protected]) is an associate professor at China University of Petroleum, Beijing, and a senior scientist at China State Key Laboratory of Heavy Oil Processing. He was a visiting scholar at Canada National Research Council, Ottawa. Xu is specialized in heavy oil chemistry and processing technology, and supercritical fluid extraction. He is a coinventor of the SELEX-Asp technology and noncombustible uses for asphaltenes. He holds a BS (1991), MS (1994), and PhD (2010) in chemical engineering, all from China University of Petroleum.

Suoqi Zhao ([email protected]) is a professor at China University of Petroleum, Beijing, and a deputy director at China State Key Laboratory of Heavy Oil Processing. He was a visiting scholar at Canada National Research Council, Ottawa. Zhao is specialized in heavy oil chemistry and supercritical fluid technology. He is a coinventor of the SELEX-Asp technology and noncombustible uses for asphaltenes. He holds a PhD (1994) in chemical engineering from China University of Petroleum.

Chunming Xu ([email protected]) is a professor and a former vice-president at China University of Petroleum, Beijing, and also serves as a deputy advisory chair at China State Key Laboratory of Heavy Oil Processing. Xu was a visiting scholar at Syncrude Research Center, Edmonton. His research interests include heavy oil chemistry and processing technology. He is a coinventor of the SELEX-Asp technology and noncombustible uses for asphaltenes. Xu holds a BS (1985), MS (1988), and PhD (1991) in chemical engineering, all from China University of Petroleum.