Indian refinery nears startup of major expansion, modernization project

State-owned Hindustan Petroleum Corp. Ltd. (HPCL) is entering the final stages of completing its long-planned program to expand and modernize its 166,700-b/d (8.3 million tonne/year) Vishakhapatnam (Visakh) refinery in Andhra Pradesh on India’s southeastern coast.

Approved by the government of India in 2016 and scheduled to be progressively commissioned beginning midyear 2020, the Visakh refinery modernization project (VRMP) will increase crude oil refining capacity of the site to more than 300,000 b/d (15 million tpy) as well as boost production of low-sulfur fuels conforming to Euro 5 and Euro 6-quality standards (OGJ Online, Jan. 19, 2016).

Background

Initially proposed to the Expert Appraisal Committee of India’s Ministry of Environment, Forests, and Climate Change (MOEFCC) in 2013 for review, HPCL’s brownfield VRMP was designed to support the operator’s strategy to ensure long-term profitability and competitiveness of the Visakh refinery in view of India’s projected demand growth for petroleum products.

VRMP was to include both installation of new units and revamps of existing units to expand the Visakh refinery’s processing capacity by 6.7 million tpy to 15 million tpy, as well as boost its production of low-sulfur fuels that conform to Bharat Stage (BS) IV and BS V-grade (equivalent to Euro 4 and Euro 5-quality) fuels standards.

As originally planned, HPCL was to add the following new units and capacities as part of the project:

- A 9 million-tpy combined crude distillation unit (CDU) and vacuum distillation unit (VDU), which will replace one of Visakh’s three existing CDUs.

- A 3.3 million-tpy vacuum gas oil hydrocracker (VGOH).

- A 290,000-tpy naphtha isomerization unit (NIU).

- A 3.1 million-tpy solvent deasphalting unit (SDA).

- A 2.5 million-tpy slurry hydrocracker (SHCU).

- A 96-tonne/day propylene recovery unit (PRU).

- Two 113,000-tpy hydrogen generation units (HGU; 226,000 tpy total).

- Two 360-tonne/day sulfur recovery units (SRU; 720 tonnes/day total, including tail gas treatment).

- A 36,000-tpy fuel gas pressure-swing adsorption unit (PSA).

- A 300-tonne/hr nonhydroprocessing sour-water stripper (NHSWS).

- A 185-tonne/hr hydroprocessing sour-water stripper (HSWS).

- Two 540-tonne/hr amine regeneration units (ARU; 1,080 tonnes/hr total).

- A 112,000-tpy sulfur recovery LPG treating unit (SRLPGTU).

- A 1,000 cu m/hr integrated effluent treatment plant (IEFP), which will replace all existing EFPs at the site.

In June 2019, however, HPCL officially notified MOEFCC that, upon originally conceiving the VRMP, India’s directive of 100% compliance with BS-VI (equivalent to Euro 6-quality) fuel implementation as of Apr. 1, 2020—announced on Jan. 6, 2016—had yet to be established. As a result, HPCL updated capacity configurations of the VRMP during the project’s detailed engineering phase.

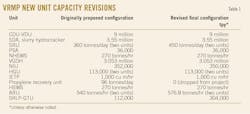

Table 1 shows the VRMP’s original and revised, final capacity configurations for newly proposed units to conform with India’s BS-VI 2020 fuel implementation.

Alongside new unit capacities, HPCL and project contractor Engineers India Ltd. also notified MOEFCC of revisions to proposed existing unit revamps to conform with India’s upcoming fuel regulations, particularly with respect to the refinery’s Motor Spirit (MS, gasoline) block.

Table 2 shows the VRMP’s original and revised capacity configurations for revamps of existing units.

As of June 20, 2019, HPCL estimated total cost of the VRMP at 209.28 billion rupees, up from its original planned investment of 208 billion rupees in 2016 (OGJ Online, Jan. 16, 2017).

VRMP contractors

Following its contract award to EIL to provide project management consultancy and engineering, procurement, and construction (EPC) services for major processing units, as well as related utilities and off sites to be added during the VRMP in early 2017, HPCL let a contract to Larsen & Toubro Ltd. subsidiary L&T Hydrocarbon Engineering Ltd. (LTHE) to provide engineering, procurement, construction, and commissioning (EPCC) services for the VRMP’s full-conversion hydrocracker (OGJ Online, Dec. 17, 2017).

In March 2017, the operator let a contract to Honeywell UOP LLC to provide licensing, basic engineering design, and other associated services for UOP’s proprietary Penex isomerization unit (for production of high-octane gasoline) as well as its branded Unicracking hydrocracking unit (for production of diesel) for the project.

Alongside helping to improve the refinery’s gross refining margins by converting low-quality feedstock into high-quality transportation fuels, the Penex and Unicracking units also will support Visakh’s ability to meet rising demand for BS VI-grade fuels in accord with the Indian government’s proposal to reduce carbon emissions by 35% by 2030.

In January 2018, HPCL let an additional contract to LTHE to provide EPCC services for the VRMP’s new CDU-VDU.

Later in first-quarter 2018, HPCL awarded a contract to Bharat Heavy Electricals Ltd. (BHEL) to set up a gas turbine-based captive power plant (CPP) to be built as part of the VRMP.

As part of the 10.34 billion-rupee, lump-sum turnkey contract, BHEL was to deliver engineering, manufacturing, supply, transportation, construction, commissioning, and civil works on one gas turbine generator, one heat-recovery steam generator, and one steam-turbine generator, as well as associated auxiliary installations for the VRMP. The addition of the CPP is intended to help meet power and steam requirements for the project.

In mid-2018, HPCL let another contract to LTHE to provide EPC services for the new IETP included in the VRMP (OGJ Online, June 11, 2018). The IETP contract covers all modern technologies related to oil removal from refinery effluent, including the sequencing batch reactors-based treatment of 1,000 cu m/hr of refinery effluent, a membrane bioreactor-based sewage treatment system, a wet air oxidation-based spent caustic treatment system, and a volatile organic compound control system.

Alongside EPC, LTHE scope of work on the project will include erection, installation, testing, and commissioning of the IETP, which will cater to the future requirements of existing projects and replace all existing ETPs at the Visakh refinery.

In July 2018, HPCL awarded a contract to TechnipFMC to deliver technology licensing and EPCC services for the new HGU to be added as part of the VRMP (OGJ Online, July 20, 2018). The contract—valued at $250-500 million—covers project management, technology licensing, preparation of basic design, and engineering package, as well as detailed EPCC, and a performance-guarantee test run for the HGU, which will include two 113,000-tpy trains and a PSA unit with a hydrogen production capacity of 36,000 tpy.

As part of the contract, TechnipFMC will equip the unit with its proprietary steam-reforming technology, including its branded TechnipFMC Parallel Reformer (TPR)—a convective, high-temperature heat exchange reformer—which will reduce overall firing demand by taking high-temperature heat from effluent of the conventional reformer to supply heat needed for the TPR. The unit design additionally will include a power-generation unit that uses excess steam, making the plant electrically self-sufficient.

Later in 2018, HPCL let a contract to Chevron USA Inc.-McDermott International Inc. joint venture Chevron Lummus Global LLC (CLG) to license technology for the VRMP’s grassroots vacuum residue upgrading unit (RUF) (OGJ Online, Sept. 27, 2018). Alongside designing the new unit based on its proprietary LC-MAX and ISOTREATING technologies, CLG also will supply catalysts, proprietary reactor internals, and provide training and technical services.

A cornerstone of HPCL’s refinery expansion strategy, the new RUF will enable HPCL to convert the heaviest oils at the Visakh refinery to produce high-quality BS-VI diesel while simultaneously eliminating fuel oil production at the site, as well as increasing feedstock and product flexibility. Late in 2019, HPCL also awarded a third contract to LTHE to provide EPCC services for the new RUF.

In November 2019, HPCL awarded a contract to KBR Inc. to license its proprietary residual oil solvent extraction (ROSE) solvent deasphalting (SDA), which will be integrated with the LC-MAX technology ebullated-bed residue upgrading process from CLG for the RUF (OGJ Online, Nov. 12, 2019). Specifically, KBR will deliver CLG the technology licensing, basic engineering design, and proprietary equipment for the ROSE SDA portion of the LC-MAX unit.

Progress to date

While HPCL has yet to detail specifics related to fully completed portions of the VRMP, the operator and its contractors involved in the project have confirmed general progress of delivery and installation of major units and equipment included in the program.

In early 2019, Larsen & Toubro said it completed and flagged off to HPCL a 1,885-tonne hydrocracker reactor—now India’s heaviest—for the VRMP (OGJ Online, Mar. 29, 2019). This first reactor will join several other hydrocracker reactors weighing more than a combined 2,000 tonnes that were still in the process of manufacturing for the RUF portion of the VRMP.

HPCL was setting up the first and second-stage reactors of the VRMP’s full-conversion hydrocracker unit (FCHCU) in June 2019, which the operator said would be India’s largest (Fig. 1).

In late 2019, heavy-lift contractor Mammoet lifted five major components for the VRMP at the refinery site, include the CDU-VDU columns, followed by three reactors and other lighter columns for the FCHCU (Fig. 2).

HPCL plans to reach mechanical completion of and begin phased commissioning of the VRMP in July 2020, the operator told investors in its most recent update on the project.