Equipment/Software/Literature

New multigas detector has plug-in sensors

As many as six gas hazards can be measured and monitored simultaneously via this new G750 Polytector II gas detector.

Exchanging and adding smart sensors help adapt the compact instrument easily to changing conditions. It's simple and reliable in handling and features an impactproof enclosure. All measured gas concentrations are shown simultaneously on the graphic display, which is illuminated and provides a zoom function for individual readings.

The warning system gives a visual and audible (90 db) alarm when a gas builds up a dangerous concentration.

Only a few keys are sufficient for operation. The gas supply is effected either via diffusion or by means of a built-in, strong sampling pump from distances of as far as 30 m. This helps make sure that there is no gas hazard in confined areas. The sampling mode does not require an additional pump adapter; just press the key.

The battery pack also may be replaced in hazardous areas.

An optional data logger stores peak, average, or instantaneous values together with date, time, and location.

Fully equipped with six sensors, battery pack, and pump, the Polytector weighs only 770 g.

These gases can be monitored: combustible gases and vapors (e.g., CH4, H2, C3H8), CO2, O2, CO, NH3, H2S, NO, NO2, SO2, Cl2, PH3, SiH4, HCN, C2H4O.

For carbon dioxide the firm uses the proved infrared detection principle.

Source: GfG Gesellschaft für GMBH, Klönnestrasse 99, D-44143 Dortmund, Germany.

New software tool aids pipeline operations

PipeView Integrity is a new software tool to help transmission pipeline operators and local distribution companies assess and manage the integrity of their pipelines.

The program seamlessly manages multiple types of pipeline integrity and facility data in a single environment. It integrates information from databases and GIS platforms. The information includes data from pipeline assets as well as in-line inspection tools and above ground surveys.

The new software helps pipeline operators maximize safety and asset life by assessing their lines for potential risks. The tool supports informed decisions by helping operators develop appropriate maintenance and repair plans.

Its new PipeView application platform includes a data-access component, a feature that allows the various PipeView Integrity tools—including risk assessment, integrity planning, integrity data manager, and feature assessment—seamlessly to merge various information sources into a single environment.

The program replaces two of the company's existing tools. The first one, PipeView Risk, was produced by Kansas City, Mo.-based M.J. Harden Associates Inc., a geospatial data management company acquired in 2003. The second tool, PRIMA, was designed by GE Energy's pipeline integrity operation headquartered in Northumberland, England.

Source: GE Energy, 4200 Wildwood Parkway, Atlanta, GA 30339.

New oil spill remedy

Bilge-Medic is a new product that breaks down oil and other fuels that have been spilled into boat bilges or waterways.

The company says its product renders these flammable substances harmless, preventing explosions in contained areas and significantly reducing the damage done by fuel that has been released into the environment.

It is approved by the US Environmental Protection Agency for use on hydrocarbon-based substances. In addition, it has been certified by the International Maritime Organization and the American Bureau of Shipping along with being approved by the US Department of Agriculture, US Federal Aviation Administration, and Underwriters' Laboratories of Canada as a Class A and B fire fighting agent.

Bilge-Medic works through a chemical process and contains no bacteria or enzymes.

When the product is agitated with water, it coats and disperses oil and fuel at a molecular level, eliminating vapors and accelerating the natural breakdown of these materials.

Source: Crew Cleaner Inc., 6874 NW 20th Ave., Fort Lauderdale, FL 33309.

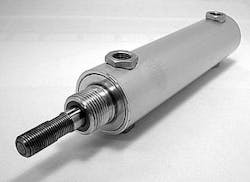

Lube-free cylinders have Teflon seals

In this lubrication-free round body Centaur cylinder, Teflon seals provide low breakaway force.

These cylinders, designed to match tie-rod performance, serve a range of mobile equipment applications.

Because the cylinders are not permanently crimped, they can be disassembled for maintenance.

The maker says these cost effective units typically cost 45% less than standard models over the full range of sizes—including 11/8-3 in. bore sizes.

Bumpers are built into each cylinder head to eliminate the metallic clank that occurs at stroke completion and reduce wear.

The flush bottom cylinder mounts directly to a base plate and needs no mounting brackets or other hardware.

Source: Mead Fluid Dynamics Inc., 4114 N. Knox Ave., Chicago, IL 60641.