Coalbed methane growing rapidly as Australia gas supply diversifies

With the recent entry of both coalbed methane from the Bowen, Surat, and Sydney basins and conventional natural gas from new offshore fields in the Gippsland, Bass, and Otway basins, the eastern Australian gas market has undergone significant change.

These new projects are competing with traditional gas supplies from the Cooper and offshore Gippsland basins and will face increased competition from the proposed Papua New Guinea-Queensland gas pipeline.

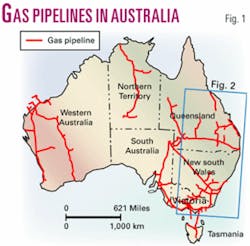

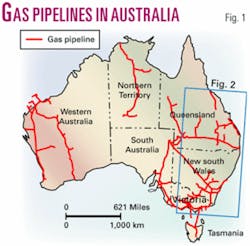

Conventional natural gas reserves in fields close to eastern Australian markets are declining while gas demand continues to grow substantially. CBM resources are located close to large potential markets in eastern Australia where the gas pipeline network is rapidly expanding (Figs. 1 & 2).

CBM exploration and production were of little significance in Australia until the late 1990s but are becoming an integral part of the Australian gas industry. The successful development of CBM fields has contributed to the diversification of gas supply sources, particularly in Queensland. CBM is poised to continue as an important energy source in Australia.

CBM and coalmine methane

CBM is the naturally occurring, methane-rich gas in coal seams and commonly known in Australia as coal seam gas or coal seam methane.

The CBM that is associated with coal mining is traditionally called coalmine methane. A total of 300,000 m of directional in-seam drilling is carried out every year for degasification purposes to enhance minesite safety at underground and highwall open-cut collieries in the Bowen basin in Queensland and the Sydney basin in New South Wales. In comparison, about 184,000 m were drilled for stand-alone CBM exploration or production in 2004 in Australia.

About 51 PJ of coalmine methane were emitted to the atmosphere in Australia in 2004. This is 111% of the commercial production of CBM in Australia or about 5% of Australia’s total primary domestic gas consumption in the same year. Drained coalmine methane is used at several collieries as either pipeline gas or fuel for on site electric power generation.

The coalmine methane that is emitted through mine ventilation systems is called ventilation air methane, which is the largest source (about 58% in Australia) of coalmine methane emissions. Ventilation air methane is also an untapped potential energy resource.

The potential use of mine ventilation air is largely restricted to on site power generation, because its methane content is very low (generally less than 1%). Specialized combustion reactors that can burn ventilation air methane are being installed at the Westcliff colliery in the Sydney basin.

Coalmine methane drainage and CBM resources are separately administered in both Queensland and New South Wales: the former by mineral resources legislation and the latter by petroleum resources legislation. In Victoria, however, CBM resources are administered under the legislation for mineral resources development.

As CBM is contained within the coal, conflicts between a developer of coal and coalmine methane and a developer of CBM can occur in an area where the CBM resource is located within a potentially economically minable coal deposit.

A new gas scheme was introduced in Queensland in January 2005. Designed to encourage the development of new gas supply sources such as CBM, the scheme requires electricity retailers to source at least 13% of their electricity from gas-fired generation or renewable resources. The 13% gas scheme has already acted as a catalyst for active exploration and development programs for CBM in Queensland.

Exploration and production

CBM exploration is based on hydrocarbon play concepts. However, traditional petroleum exploration theories and drilling practices are not necessarily applicable to CBM exploration and drilling. Permeability and gas content are the most important properties for CBM exploration and development.

CBM accumulations are not necessarily related to the presence of anticlines. However, many CBM project areas are located on anticlinal trends, although not all of these anticlines may form valid structural closures. In addition, CBM project areas are often located near conventional gas fields.

Anticlinal trends are attractive targets for CBM exploration because the depth to a coal seam is often less on an anticline than on its flanks and also because fracture development is often more intensive along the anticlinal axis.

The capital cost of drilling a CBM well has decreased greatly in the last decade, with fit-for-purpose drilling technologies tried and developed on site in Australia. Some new production wells comprise pairs of a horizontal drainage well and a directly connecting vertical production well or trios of two horizontal wells and a vertical well.

CBM drilling activity has been increasing substantially in terms of both the number of wells and metres drilled. A total of 277 CBM exploration or development wells were drilled in 2004 (Fig. 3). In comparison, 201 conventional petroleum exploration or development wells were drilled onshore or offshore in Australia in the same period.

The Permian Bowen basin remains the most actively explored and developed basin in Australia for CBM. The basin’s share of CBM drilling activity exceeded 80% of Australia’s total in 2004 in terms of number of wells and metres drilled. Wells are typically about 700 m deep in this basin.

A recent trend in CBM exploration is for resources at shallow depths in low-rank (low thermal maturity) coal seams of Jurassic age in the Surat basin in Queensland and in the Clarence-Moreton basin in Queensland and New South Wales. Wells are typically about 500 m deep in the Surat basin.

Lignite (brown coal) of Tertiary age has also become a target for CBM exploration. This new trend is based on the observation that, in spite of a smaller amount of CBM initially in place per unit volume of coal, low-rank coal at shallow depths (100 to 500 m) is more permeable than high-rank coal of Permian age at intermediate depths. Thus, CBM could be more easily desorbed from low-rank coal than from high-rank coal, resulting in a higher recovery factor.

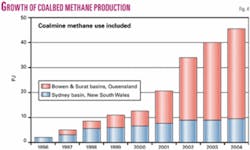

The commercial production of CBM (including coalmine methane use) has increased substantially since 1996, when coalmine methane use began in the Moura colliery in Queensland. Production is estimated to have reached 46 PJ/year in 2004 in Australia (Fig. 4).

Cumulative CBM production is about 179 PJ from 1996 to 2004. CBM production in Queensland was about 36 PJ/year in 2004, satisfying about 31% of Queensland’s total primary gas demand. CBM production in New South Wales was about 10 PJ/year in 2004, and much of this came from coalmine methane use at the Appin and Westcliff collieries.

Gas content

Subsurface coal contains a significant amount of CBM.

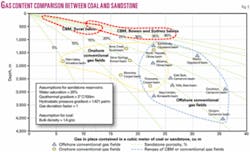

Fig. 5 shows a relationship between depth and gas initially in place contained in a unit volume of coal or sandstone.

For example, 1 cu m of coal in the Bowen and Sydney basins contains 11 to 27 cu m of CBM initially in place (at standard conditions of pressure and temperature) at depths of between 300 and 900 m. In comparison, 1 cu m of sandstone with a porosity of 20% in Goodwyn field in the offshore Carnarvon basin contains 37 cu m of conventional gas initially in place at a depth of 2,900 m.

A cubic metre of fractured sandstone with a porosity of 5% in Palm Valley field in the onshore Amadeus basin contains only 6 cu m of conventional natural gas initially in place at a depth of 1,800 m.

Fig. 5 indicates that gas initially in place per unit volume of coal in CBM fields is of a similar range (5 to 27 cu m/cu m of coal) to that of sandstone at typical depths in onshore conventional gas fields. A cubic metre of a hypothetical sandstone reservoir with a gas saturation of 80% at a depth of 700 m would require a porosity of 35% to match the gas content of 1 cu m of coal containing 20 cu m of CBM initially in place at the same depth in the Bowen or Sydney basins.

Gas reserves

The percentage of the discovered CBM initially in place that can be considered as recoverable to surface above a certain cutoff flow rate per well for a certain minimum period with the use of existing or emerging technology is not well understood.

It is not uncommon for CBM operators in Australia to assume recovery factors of 15% to 70%.

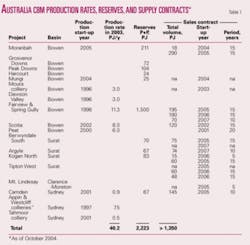

Table 1 lists information on CBM reserves, production rates, and supply contractual volumes for individual projects as of October 2004.

A total of 2,223 PJ (2,020 bcf or 57.2 bcm) of proved plus probable CBM reserves has been reported in CBM fields and pilot production areas in Australia. Of these reserves, 1,936 and 220 PJ occur in the Bowen and Surat basins, respectively.

These figures compare with the total cumulative production (764 PJ) and proved plus probable reserves (294 PJ) of conventional gas in the two basins combined. This shows that CBM reserves are nearly twice as large as the ultimate recovery of conventional natural gas in these two basins.

The adjoining Fairview and Spring Gully fields in the Bowen basin contain 1,500 PJ of proved plus probable CBM reserves. This volume is greater than the ultimate recovery of conventional natural gas from the entire Bowen and Surat basins, where a total of about 850 conventional gas or oil exploration wells have been drilled. This CBM field complex is also larger in ultimate recovery than the largest onshore conventional gas field discovered in Australia (Moomba field in the Cooper basin in South Australia).

Due to the decline in conventional gas reserves in the Cooper, Bowen, and Surat basins, new gas supply contracts in Queensland have shifted to CBM. In recent years, a number of supply contracts have been exchanged to sell more than 1,350 PJ of CBM to the operators of pipelines, electric power generators, a refinery, and manufacturing plants in Queensland and New South Wales (Table 1). This means that 61% of the total proved plus probable reserves (2,223 PJ) have already been allocated for supply contracts.

Energy projections

The total primary consumption of natural gas (conventional natural gas plus CBM) in Australia was about 1,053 PJ in 2004, according to Australian Bureau of Agricultural and Resource Economics (ABARE) energy supply and disposal projections.

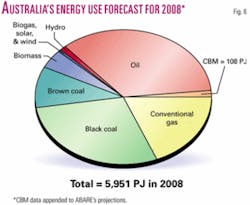

This compares with Australia’s total primary energy consumption of 5,333 PJ in the same year. Thus, annual CBM production of 46 PJ accounted for 4.4% of Australia’s total primary consumption of natural gas and 0.9% of Australia’s total primary consumption of energy in 2004. Energy from CBM is likely to exceed that from hydroelectricity generation by the end of 2005.

Existing supply contracts indicate that a total of 108 PJ of CBM will be supplied annually by the end of 2007, and that this amount will represent 8.4% and 1.8% of Australia’s total primary consumption of gas and energy, respectively, in 2008 (Fig. 6). In Queensland, the ratio of primary CBM consumption to total primary gas consumption will increase from 31% in 2004 to 62% in 2008, suggesting CBM will be supplying most of the baseload sales gas by 2008.

It is not unusual in the CBM industry for contractual supply volume to be larger than the publicly announced proved plus probable reserves at the date of contract exchange. Reserves certification is often carried out after the exchange of the contract. This practice may potentially lead to a less objective certification of reserves.

Technical challenges

As production of CBM in Australia increases, requirements for accurate estimates of CBM reserves and production forecasts become increasingly important.

Analogs of conventional gas fields are often applied when estimating a recovery factor for a CBM project. A volumetric estimation method is commonly used for calculating CBM initially in place, although the mechanism for CBM production is fundamentally different from that found in conventional gas production.

CBM is stored in the coal by adsorption, but the desorptive nature has not always been taken into consideration when calculating CBM reserves. The production decline characteristics of CBM may not necessarily be analogous to those of conventional gas.

The volumetric method appears not always to take account of the minimum economic production rate of CBM, although production decline characteristics are site-specific and largely unknown. For these reasons, a CBM reserves estimate derived from a volumetric method may not always be as reliable as a conventional natural gas reserves estimate derived by the same method.

Operation of a production well for CBM is inflexible in that the gas flow rate is not as easily controlled as in a conventional gas well. As CBM is produced at low wellhead pressures, gas compression to pipeline specifications adds significantly to operating costs.

A CBM well requires continuous dewatering to release gas. Production is as much a water management exercise as it is a CBM production exercise. Continuous water production and the treatment and disposal of the produced water are major cost issues. Further, the effect of water production on the regional aquifer system may not be well understood. As many project areas are located on agricultural lands, a conflict may occur between a CBM producer and other land users.

The inflexibility of CBM production rates may result in a price discount compared to conventional gas. Low start-up cost is a major attraction for the CBM industry. Gas produced during the production decline phase, however, is usually expensive relative to conventional gas resulting from the labor-intensive nature of CBM development.

In addition, because of low production rates per well, CBM is unlikely to become a major source of natural gas in a national context, regardless of the very significant volumes of CBM initially in place. However, it is becoming very important in some regional areas.

It is difficult to predict the change in methane content of produced gas during the production life of a CBM field. Air may break through into the well from the atmosphere at a late stage of production as a result of continuous dewatering, and the presence of numerous cleats (microfractures) in the coal could provide the air with a conduit. Air breakthrough could terminate prematurely the production life of a well.

Uncertainties associated with predicting the magnitude and duration of peak production period of a CBM well are the main sources of potential inconsistency in reserves estimation between CBM deposits and conventional natural gas reservoirs.

There is a high turnover of production wells during CBM production as the economic life of a CBM well is shorter than that of a conventional gas well. These production performance uncertainties can only be minimized through empirical experience gained from long-term CBM production.

Further expansion of the CBM industry depends largely on the medium-term production performance of the pioneering production projects currently in operation. ✦

Based on a paper presented at the 45th annual Australian Petroleum Production and Exploration Association conference, Apr. 10-13, 2005, Perth.

The author

Shige Miyazaki ([email protected]) is a senior geologist with the petroleum and marine division of Geoscience Australia, evaluating the development geology of offshore oil or gas accumulations. He started his career as an international exploration geologist with Japan National Oil Corp. in Tokyo. After immigrating to Australia, he worked for the Bureau of Mineral Resources and Bureau of Resource Sciences. He has a master’s degree in earth sciences from Nagoya University.