NOx-trading recoups emission-retrofit costs for compressor engines

Based on a presentation to 83rd GPA Convention, New Orleans, Mar. 14-17, 2004.

An analysis has been conducted of several NOx emission-reduction project alternatives suitable for two-stroke lean burn (2SLB) and four-stroke lean burn (4SLB) natural gas engines used as gas-compression drivers.

Operators of such engine sources have several alternatives for reducing NOx emissions, including combustion retrofits, ignition retrofits, exhaust after-treatment, replacement with electric motor drive, replacement with low-emissions engine drive, or a combination of these options.

Specifically, the analysis described in this article examined the economics and performance of selective catalytic reduction (SCR) in conjunction with ignition/combustion retrofits even though, so far as the author knows, no engine installation uses SCR in conjunction with other NOx-reduction ignition/combustion retrofits.

Some installations, however, use exclusively either SCR or ignition/combustion retrofits to reduce NOx.

This article explores the potential synergies of these technologies, while explaining individual case studies of each.

The analyses quantify capital, installation, and operating costs; effects on fuel consumption; effects on reliability and operability of engine and control equipment; greenhouse gas and criteria pollutant reductions; and emission-reduction benefits applicable to participation in emissions-trading programs.

Stationary reciprocating natural gas engines, used extensively throughout the natural gas gathering and transmission industry, are targets of US and state air regulatory authorities for significant reductions in NOx emissions.

Emissions trading

In coming years, a convergence of federal, state, and local emission regulations will affect a growing number of reciprocating engines used in gas compression applications.

"Cap-and-Trade" programs have demonstrated success in reducing pollutants and their harmful effects, as is the case with federal acid-rain programs targeting the reduction in SOx emissions.

These cap-and-trade programs, emerging in many markets across the US, are now targeting NOx and volatile- organic-compound (VOC) pollutants with the intent of minimizing the ingredients active in the formation of ground-level ozone.

Cap-and-trade programs place a mass emissions cap on pollutant emissions within a given geographic control area, such as an ozone nonattainment area. Pollutant sources within the control area receive pollutant "allowances," or the right to emit a mass quantity of pollutant within a given time period. Such allowances are usually expressed in tons per year (tpy).

Over time, a governing authority reduces the available allowances as a means of reducing the mass emission of pollutants and achieving air-quality improvements.

As an operator's allowances decrease, the operator must either install controls to reduce pollutants to the allowed level, curtail operations to reduce pollutants, purchase additional allowances on the open market to continue operating at the same emission rate, or cease operation within the control area.

Conversely, if the operator chooses to operate below his allowance level voluntarily, the operator generates an emission credit that can be bought, sold, or banked.

The supply-demand balance of available allowances on the open market governs their market value. Thus, operators frequently evaluate control technologies on a "dollars per ton of pollutant reduced" basis.

Allowance valuations justify the timing, point source, and emission-control technology suitable for emissions-reduction projects.

Critics argue, however, that such cap-and-trade programs capture economic value rather than create it and that open-market emissions trading requires extensive oversight and governance to avoid abuse and misuse.

Fletcher and Williams present a detailed explanation of emerging emissions-trading programs and the opportunities they can provide for use as a source of funding necessary infrastructure upgrades within the gas transmission industry.1

The objective of the current discussion is to explore the feasibility of emissions trading used as a funding source to recoup capital, installation, and operating costs of emission-control retrofits when operated to reduce emissions from reciprocating engines.

Another objective is the identification of potential synergies with the combination of low-emission combustion (LEC) retrofits and selective catalytic reduction (SCR) exhaust after-treatment.

This analysis quantifies the costs and benefits of these two control retrofits in light of currently available technology and presents market conditions for open-market emissions trading in the US.1-5

Retrofit technologies

Confronted with the need to reduce emissions from natural gas reciprocating engines, operators face numerous choices, including combustion retrofits, ignition retrofits, exhaust after-treatment, replacement with electric-motor drive, replacement with low-emissions engine drive, or a combination of these.

Over the past 10 years, LEC retrofits have been a common choice of operators of 2SLB and 4SLB engines used in domestic gas compression applications.1

In recent years, SCR exhaust after-treatment has demonstrated its effectiveness for NOx reduction in 4SLB gas compressor applications in Europe.3

In the US, SCR is widely used for 4SLB natural gas engines operating in power-generation applications6 but is less common for gas compressor applications.

A typical LEC retrofit yields a significantly reduced NOx emissions rate as well as a reduced brake specific fuel consumption (BSFC).

The scope of the LEC retrofit varies by engine and can include modifications to the ignition system, fuel delivery system, air delivery system, and air-to-fuel ratio control (AFRC) system.

Specific hardware upgrades/replacements that may be needed include turbochargers, waste gates, camshafts, pre-combustion chambers, and an auxiliary cooling system for the pre-combustion chambers.2

The principle of an LEC retrofit is to operate the engine at a lean air-to-fuel ratio in order to obtain the benefits of lower NOx emissions and improved fuel economy.

The hardware and controls are designed to provide additional air necessary for operating at a lean air-to-fuel ratio, enhance the mixing of the air and fuel for complete combustion, and ensure ignition of the lean air-to-fuel mixture.

SCR retrofits use an exhaust after-treatment approach for NOx reduction in oxygen-rich exhaust streams.

The scope of the SCR retrofit includes the catalyst and reactor housing; exhaust piping modifications (flow dressers, reductant injector assembly, flow mixers); a storage, metering, and injection system for the consumable reductant; and a control panel to interpret various inputs from the engine and SCR reactor (load, speed, run signal, exhaust temperature, ppm NO), and meter the injection of the reductant.

Oxidation catalysts are used to provide carbon monoxide (CO), unburned hydrocarbon (HC), and/or formaldehyde (HCHO) oxidation.

Special formulation oxidation catalysts may also be used downstream of the SCR catalyst reactor to reduce ammonia slip while avoiding NOx creation that would be observed with a standard oxidation catalyst.

The principle of SCR exhaust after-treatment is to use a consumable reductant (typically a 40% aqueous urea solution) to reduce NOx through a catalyst.

The catalyst and controls are designed to monitor changing engine and catalyst conditions and precisely meter and inject the reductant necessary for minimizing NOx emissions and ammonia slip over the load and speed range of the engine.3 6

Working in conjunction with one another, LEC and SCR retrofits have the potential for several synergies.

Current SCR technology requires a minimum exhaust temperature of 600° F. (316° C.), and some LEC retrofits of 2SLB and 4SLB engines may preclude the use of SCR because of the cooled exhaust temperatures.

For applications in which this temperature limitation is not an issue, the LEC retrofit will significantly reduce the operating costs for the SCR system.

The cost of the urea solution reductant predominates the operating expense of SCR systems, and the urea consumed in the reactions to reduce NOx is directly proportional by mass to the quantity of NOx reduced.

By significantly lowering the NOx emissions from the engine, the LEC should significantly reduce the operating expense of the SCR.

Simultaneously, the SCR will be reducing the already-low NOx concentrations achieved by the LEC retrofit, thus generating additional mass reductions in NOx that can be claimed for use in open-market emissions-trading programs.

Combined, the control systems for the SCR and LEC potentially comprise a continuous emissions-monitoring system (CEMS) equivalent control system, providing credible and quantifiable evidence of the emissions performance achieved.

Based on the current and growing sophistication of these combined technologies, they present a solution for compliance-assurance monitoring (CAM) programs and, with minor enhancements, present a CEMS solution. Having a CEMS system is a requisite for a voluntarily opt-in to some cap-and-trade programs, such as the NOx SIP Call rule.1 (SIP = state implementation plan)

Finally, the SCR retrofit, in conjunction with the LEC retrofit, achieves significantly lower NOx levels than are currently mandated in most areas of the country, allowing older gas compressor engines to operate longer while meeting future stringent emission requirements.

Emissions trading

Fletcher and Williams categorize three programs of emissions trading in present use that provide a financial payback for quantifiable and certifiable emissions reductions:1

- Offset programs, used in nonattainment areas, provide a mechanism for compliance with offset requirements imposed by the addition of new emitting sources or the expansion of existing sources. The measure for offset programs is a rate-based currency, such as lb/hr or tpy.

- Cap-and-trade programs, described earlier, use a mass-based allowance for their currency, such as pounds or tons of pollutant.

- Open-market programs also use a mass-based currency. A lack of regulatory drivers, however, is inhibiting their adoption in many jurisdictions. Open-market programs, such as the Ozone Transport Commission (OTC) and NOx SIP Call rules, assist operators in compliance with existing regulations, such as reasonably available control technology (NOx RACT).

The primary currencies for these programs may include any or all of the following:

- Emission reduction credits (ERCs) are a rate-based currency, with units of lb/hr or tpy. An ERC represents a "saleable and seemingly perpetual stream of emissions reductions." 1

- Discrete emission reductions (DERs) are a mass-based currency, using units of pounds or tons of pollutant. Unlike ERCs, DERs are not perpetual streams of emissions reductions; once a purchased DER is "consumed," it must be replenished in subsequent time periods during which the source will be emitting DER mass units of pollutants.

- Allowances are typically issued annually by the administrator of the cap and trade program. Thus, they use a mass-based currency that gives the holder the right to emit a given mass of pollutant during the specified period.

Program rules establish guidelines for initial allowance disbursements based on historical levels of activity, step-down timelines for reductions in annual disbursements, provisions for carrying forward unused allowances, and penalties when actual emissions exceed allowance allocations.

- When offsets are required, a facility may choose either to generate or to purchase the offsets, depending on the facility's circumstances and market conditions. In either scenario, generating/buying ERCs—or an equivalent production/purchase of DERs at regular intervals—would fulfill the requirements.

Many of the currencies will have restrictions placed on the future time period(s) of their use. These restrictions are defined, in large part, by the time over which the emissions reduction is initiated and generated. Several examples of restrictions are listed below.

- Individual vintage-year allowances.

- Vintage-seasonal allowances (for ozone season months, typically May through September).

- Vintage-streams of allowances (for a sequence of years).

Finally, each program is designed for a specific pollutant, such as NOx.

Based on the pollutant-emission rates from gas compressor engines and current market pricing, NOx and VOC programs are relevant to this analysis.

With future emission regulations and higher ERC and DER valuations, engine emissions of carbon monoxide (CO), formaldehyde (HCHO), and greenhouse gases (GHG) present equally viable opportunities but are not significant at the present time.

It is important for the evaluator to bear in mind that the favorable possibilities and flexibility of emissions-trading programs are reinforced with a complicated matrix of guidelines to be studied, interpreted, understood, and leveraged.

Case study

An Ingersoll-Rand model 412-KVS family engine is a 4SLB turbocharged integral engine-compressor with 12 engine power cylinders and 4 compressor cylinders.

This engine choice is prevalent in the gas-transmission-engine population and is a suitable candidate for retrofit with both LEC and SCR.

The data presented and assumptions selected in the analysis are based on available data,2 3 7 8 current market conditions in active emissions-trading markets,4 5 and current capital and operating expenses for the LEC and SCR technologies.3 7

Table 1 is an excerpt from the analysis spreadsheet and lists the engine and retrofit parameters pertinent to the analysis.

The "As-Found Baseline" defines the parameter values in the condition of a typical uncontrolled engine. "LEC" values define the condition with a low-emission combustion retrofit installed. "SCR" values represent the condition with a selective catalytic reduction system installed on the baseline engine.

The "LEC+SCR" parameter values represent a condition in which selective catalytic reduction is installed in conjunction with a low-emission combustion retrofit. Capital and installation costs appear for each of the retrofit scenarios.

Urea consumption, maintenance, consumable parts, emissions testing, verification of performance, permitting, and execution of emissions trading all comprise the calculated operating costs in this analysis. Calculated fuel costs are determined from assumed fuel price from Table 2 and the BSFC, rated power, and net availability operating hours for each scenario.

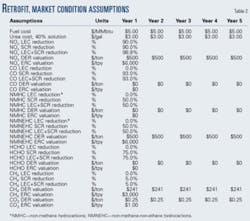

Table 2 lists the retrofit performance and market-condition assumptions for the analysis.

The spreadsheet is constructed for a 5-year calculation of costs and benefits of the scenarios.

For simplicity in this analysis, fixed assumption variables were used over the analysis period.

Costs, benefits

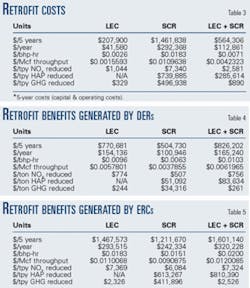

Tables 1 and 2 provide the data for constructing separate tables which itemize costs, DER-program benefits, and ERC-program benefits for the three scenarios evaluated: LEC, SCR, and LEC+SCR.

Tables 3, 4, and 5 summarize these costs and benefits.

The units selected in these summaries present the costs and benefits from a variety of perspectives.

- Dollars per year ($/yr) expresses the results for use in annual budget planning.

- Dollars per brake-horsepower-hour ($/bhp-hr) is a useful measure for maintenance budgets.

- Dollars per Mcf throughput ($/Mcf throughput) expresses the costs and benefits of these emissions-reduction retrofits in terms of the volume of gas moved by the compressor.

- Dollars per ton (per year) of NOx reduced ($/ton NOx reduced, $/tpy NOx reduced) presents the costs and benefits in a manner that is useful for comparing these retrofit alternatives among other pollution reduction choices or the applicable NOx market valuation of DERs or ERCs.

- Dollars per ton of hazardous air pollutant reduced ($/ton HAP reduced) and dollars per ton of greenhouse gas reduced ($/ton GHG reduced) provide similar comparisons for evaluation of alternatives for the pending federal MACT regulation and greenhouse gas initiatives, respectively. (MACT = maximum achievable control technology)

In Table 3, the cumulative cost dollars per 5 years ($/5 years) include the capital, installation, and operating costs incurred over a 5-year analysis period.

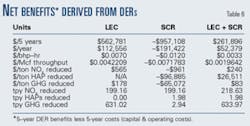

In Tables 4 and 5, the cumulative benefit dollars per 5 years ($/5 years) include an incremental fuel benefit derived from the lowered BSFC of the LEC retrofits as well as the benefit generated by the market valuations for ERCs and DERs, listed in Table 2.

In Table 4, the annual DER benefits are distributed in each of the 5 years. For Table 5, a one-time ERC benefit is distributed in Year 1.

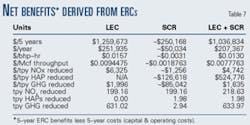

Table 6 summarizes the net DER benefits derived after the cumulative capital, installation, and operating costs are deducted from the DER benefits generated over the 5-year analysis period.

Table 7 summarizes the comparable net benefit derived from ERC-program participation.

The following variables, listed in Tables 1 and 2, greatly affect the sensitivity of the project scenario analyses:

- Available operating hours per year ("Net Availability").

- "As-Found Baseline" emission rates.

- ERC and DER valuations.

Other considerations, not included in this analysis, would carry weight in the overall decision for the scope and timing of the emission-reduction project.

Some of the emissions benefits generated by the evaluated retrofits at present do not have an applicable ERC or DER trading program to generate cash flow benefits.

Future regulations—such as MACT, offsets imposed by plant construction, or GHG initiatives—could target these pollutant species and mandate control.

The potential value derived from the deferral or avoidance of additional emissions-control expenditures necessary for compliance with future regulations is not part of this analysis but could be of favorable significance to the case studies.

The analysis spreadsheet presents a scenario of currently existing market conditions, conservative forecasts for future market conditions over the coming 5 years, current performance capabilities of LEC and SCR technologies, and current capital, installation, and operating costs of these technologies.

Because of the mentioned sensitivities in this analysis and the numerous guidelines governing emissions-trading programs and their applicability, a case-by-case project evaluation is necessary.

In round numbers, the net benefits from this study appear significant and would justify a detailed evaluation for applicability.

Ideal application

The summarized costs in Table 3 indicate the cost of compliance with present and future stringent regulations.

Considering that this analysis reflects just one compressor in the chain of compression operations from wellhead to burner tip, the costs of emissions compliance aggregate and can quickly become significant relative to the market price for the natural gas product delivered.

Urea costs weigh heavily upon the total costs of the SCR scenario, driven by the high quantity of urea required to yield significant NOx reductions from baseline conditions and the present elevated cost of urea at $3/gal. (Urea prices rose substantially throughout 2003 as a result of high demand and high natural gas feedstock prices.)

The addition of SCR to an LEC retrofit adds $71,281 to the annual costs of compliance when compared to the costs of LEC alone; the resulting emissions benefit yields a NOx emissions rate in g/bhp-hr that is well below the requirements in most areas of the country.

The summarized benefits of Table 4 are 65% funded by the NOx DERs generated for the LEC and LEC+SCR scenarios; fuel savings from a reduced BSFC yield the remaining 35% funding of the total benefit.

The SCR scenario yields no fuel savings, and the benefit is almost entirely funded by the NOx DERs generated. The addition of SCR to the LEC retrofit adds $11,104 to the annual benefit when compared to the annual benefit of LEC alone.

In Table 5, the summarized benefits are 82% funded by the NOx ERCs generated for the LEC and LEC+SCR scenarios; fuel savings from a reduced BSFC yield the remaining 18% funding of the total benefit.

The SCR scenario yields no fuel savings, and the benefit is almost entirely funded by the NOx ERCs generated.

The addition of SCR to the LEC retrofit adds $26,713 to the annual benefit when compared to the annual benefit of LEC alone.

Table 6 indicates that the LEC and LEC+SCR scenarios have a net positive benefit for this analysis: NOx emissions can be reduced significantly with a negative cost of compliance over the 5-year analysis. Emissions are reduced, and the projects produce positive cash flows.

In the scenario with SCR acting as the sole means of reducing emissions, however, DER benefits remains insufficient to offset the retrofit costs, which are dominated by the cost of the reductant solution (urea).

Like Table 6, Table 7 also indicates that the LEC and LEC+SCR scenarios have a net positive benefit for this analysis and that emissions can be reduced with the projects yielding positive cash flows.

In the scenario with SCR acting as the sole means of reducing emissions, however, even the higher-valuation ERC benefits remain insufficient to offset the retrofit costs, which are dominated by the cost of the reductant solution (urea).

Iteration revealed that a urea solution cost of $2.37/gal yields the break-even point for the SCR-ERC project cost/benefit economics.

For the LEC+SCR scenarios, revenue generated from the additional benefit derived from lower NOx emissions does not completely recoup the added costs of SCR to a simple LEC retrofit.

The added costs of SCR, however, are not sufficient to generate a negative net benefit for either the ERC or DER evaluations.

Based on the sensitivity of this analysis to certain variables, the ideal engine application for ERC or DER-funded projects will possess the following characteristics.

- High annual operating hours.

- High operating hours during ozone season.

- High NOx ERC and DER valuations in the applicable trading program.

- High established baseline uncontrolled NOx from the engine.

- Engine candidates that qualify for voluntary opt-in to emissions-trading programs.

Once a candidate engine or compressor station is identified, the recipe for a successful emission retrofit project is simple:

- Develop an understanding of the emissions-trading program.

- Identify and manage the associated risks.

- Build an analysis model driven by the variables which affect project economics.

- Monitor the market price variables which drive the model.

- Watch for the window of opportunity to open when the project economics satisfy the evaluation criteria.

Acknowledgment

The author extends thanks to the many industry colleagues who contributed the data, insights, critical feedback, and support that made this article possible: Terrie Blackburn, Bill Clary, James Mannetti, Jim McDonald, John Miguez, F. Xavier Palacios, and Steve SanMiguel.

References

1. Fletcher, C. and Williams, C., "Alternative Funding Mechanism for Gas Compression Infrastructure Upgrades," 2003 Gas Machinery Conference, Salt Lake City, Oct. 6, 2003.

2. Hopkins, E., "Transwestern Pipeline Achieves Compliance with CRB," Compressor Tech Two, July-August 2002, pp. 30-34.

3. McDonald, J., and Palacios, F.X., "SCR Catalysts for Gaz de France," Compressor Tech Two, November-December 2002, pp. 28-30.

4. Intrator, M., "NOx and Renewable Markets," Airtrends, Vol. 6, No. 6 (Oct. 8, 2003), p. 3.

5. Intrator, M., "Other US Emissions Markets," Airtrends, Vol. 6, No. 6 (Oct. 8, 2003), p. 4.

6. Newburry, D., Runnels, P., and Owings, M., "Selective Catalytic Reduction (SCR) System Installation and Commissioning at the Chow II Power Plant in Chowchilla, California," 2003 Spring Technical Conference of the ASME Internal Combustion Engine Division, Salzburg, May 11-14, 2003.

7. Miguez, J., M-Squared Products and Services, telephone interview, Dec. 16, 2003.

8. Urban, C.M., Compilation of Emissions Data for Stationary Reciprocating Gas Engines and Gas Turbines in Use by the Natural Gas Pipeline Transmission Industry, Appendix D; San Antonio: Southwest Research Institute, 1988, pp. 25-36.

The author

Don Lambert is the gas-compression division manager for Miratech Corp. and manages the company's gas compression office in Houston. He began work for Miratech in 1994 and currently oversees its North American sales to gas compression accounts. Lambert holds a bachelor's degree in mechanical engineering from the University of Tulsa, is a registered professional engineer in Oklahoma, and participates in the Gas Processors Association, Gas Compressor Association, and the American Society of Mechanical Engineers.