System-wide integrity program boosts maintenance efficiency

Robb Isaac

NDT Middle East FZE

Ahmadi, Kuwait

Monty Martin

NDT Systems & Services (Canada) Inc.

Calgary

Saleh Al-Sulaiman

Sandeep Sharma

Kuwait Oil Co.

Ahmadi, Kuwait

| Based on presentation to ASME's International Pipeline Conference, Calgary, Sept. 27-Oct. 1, 2010. |

Applying a Total Pipeline Integrity Management System (TPIMS) to a large system with numerous segments and participants yields efficiencies in both pipeline operations and maintenance.

Kuwait Oil Co. (KOC) began TPIMS implementation in early 2005 to carry out a major integrity assessment of its operating facilities, equipment, buried plant piping, and pipeline network and to establish a continuing integrity-management program. KOC Transit System is a complex infrastructure consisting of more than 300 pipelines, thousands of wellhead flowlines, and consumer and offshore lines for which a large amount of data was lost when the facilities were destroyed during the 1990 invasion by Iraq.

An initial pipeline system assessment identified issues and actions regarding condition of the pipelines, corridors, requirements on in-line inspection, documentation, risk assessment, status of international code compliance, and overall state of the system. Recommendations from that initial assessment led to the development of a long-term strategy requiring implementation of a comprehensive integrity-management program.

This article discusses the results after 5 years of using TPIMS at KOC, demonstrating some of the complex components involved in managing the integrity of the Transit System its implementation has made possible. The system made possible the integration and management of data from various sources, by conducting integrity assessment with ILI, direct assessment, and hydrostatic testing, as well as structuring a comprehensive risk and decision support mechanism.

The KOC implementation was one of the world's first of this magnitude, encompassing a wide range of services and variables, all being managed in a single environment and used by a several individuals in different parts of the company. The biggest problem in a project of this scope is data management. This article will provide examples of the integration structure to illustrate the benefits of using a single comprehensive and versatile platform to manage system requirements, ultimately providing system reliability and improving overall operational efficiency.

Background

KOC is a subsidiary of Kuwait Petroleum Corp. (KPC). KOC-KPC owns and operates the entire oil and gas pipeline network in Kuwait, more than 3,000 km of 4-56 in. OD pipelines. KOC has divided the pipeline network into four geographical regions—North, South, East, and West Kuwait—for operations. A KOC controlling team operates and maintains the pipeline network in each region.

Before the start of the TPIMS project, each region had only partial information about its pipeline network. Much of the pipeline information was lost during the 1990 Iraqi invasion of Kuwait. Whatever pipeline information remained was scattered across the various company offices. KOC took it upon itself to amalgamate and centralize this scattered pipeline information to facilitate its pipeline operations, leading to TPIMS.

Business situation

KOC carried out this TPIMS project on its own initiative, with no governing body in Kuwait requiring its implementation. There is, however, a State Audit Bureau in charge of auditing maintenance and operations within KOC. It checks to see whether international practices are being followed for work processes. The execution of a TPIMS project at this scale was a first in the Middle East.

Implementation began in 2005. Scattered paper records of pipeline material specifications and pipeline operation history were the only records available before 2005. Hardly any design drawings were available for any pipelines. There was no pipeline mapping done and pipeline routing was not fully known, as all the pipeline markers were damaged or lost during the Gulf War.

Repair and maintenance on each subject pipeline were recorded on paper and filed in the respective pipeline file. This being a manual process carried out by various KOC departments, the pipeline filing system was very difficult to keep accurate and current. Analyzing trends by looking at operational history of pipelines was also very difficult. It was almost impossible, for example, to know "how many leaks were reported for the crude lines in the west Kuwait area in the past 3 years." No unified pipeline naming convention existed within the company.

Implementing a centralized geo-database through TPIMS greatly aided KOC in efficiently storing all pipeline data and enabled it to carry out various analysis functions on its pipeline network. KOC developed a unified pipeline naming convention and properly catalogued all of its lines.

This basic pipeline information included pipe grade, OD, WT, length, coating type, operating pressure, year built, and whether lines were piggable or not. Additional information included flange ratings, leak and repair locations, and cathodic-protection data. In-line inspection data for piggable pipelines and direct-assessment data for unpiggable pipelines also entered the centralized geodatabase.

KOC conducted a differential global positioning survey with submeter level accuracy, mapping all pipeline routes in detail. The DGPS-surveyed pipeline routes, overlaid with satellite imagery of Kuwait, greatly enhanced KOC's efficiency of repairs and maintenance. The detailed routing information of the pipelines and the satellite imagery also helped KOC prioritize repairs. Locations near populated areas or near road crossings, for example, were given higher priority for repair.

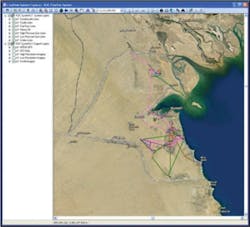

The centralized database also allowed various asset owners in different regions of Kuwait to see how their local pipeline network fit with Kuwait's overall network, aiding coordination and scheduling of maintenance (Fig. 1).

.Technical components

Many complex components affect managing the integrity of the transit system. One of the first items is who was to be the owner of the data. Privacy and confidentiality are important and having an outside company provide data services can be very delicate. All information must be protected, but at the same time accessible to all parties working on the project.

KOC established data management centers in both Canada and Kuwait. Secured sites setup at both locations hold independent, databases. Each location hosts the data on a secured network, with regular backups as well as procedures to keep the two systems synchronized. Each system uses two data-storage areas, one an industrial-strength structured query language database, and the other file-based.

The SQL server databases host the central pipeline database, as well as all aerial photography, satellite imagery, and other base map data. KOC chose to use the APDM (ArcGIS Pipeline Data Model), one of the industry standards developed to work seamlessly with ESRI-based GIS software. The TPIMS provider also shared the ESRI software development platform.

APDM implementation, however, creates difficulties in the field of data entry and data management, making it critical to have dedicated and experienced professionals in charge of data maintenance.

The folder file-based area includes individual users' project settings, raw and original data storage, report and analysis results, and an abundance of customized and standardized report templates.

Specialized software keeps the databases in sync, monitoring and track changes entered to one database and then updating the other accordingly. The folder file-based data use a document management system to keep an inventory of all data folders and files in a specific repository. The system retains a history of changes and a memory of files that have been added, modified, or deleted in case a user ever wants to step back in time and restore any of them for any reason. This vault technique allows all registered and password-protected users to access, edit, and add new files depending on their permissions. Users can also check in and check out data to notify others that certain files and data-stores are being worked on exclusively.

Project scope

The project sought to digitize and centralize any information deemed relevant to the overall integrity of the pipeline network while at the same time minimizing the effort required to mitigate hazards and threats to the assets. Such threats include, but are not limited to:

• Time-dependent (corrosion, microbiologically influenced corrosion, stress corrosion cracking, etc.).

• Time-independent (third-party damages, incorrect operations, equipment failure, etc.).

• Consequence-related (populated areas, environmental concerns, loss of product or production, potential repair and remediation costs, etc.).

Performing a rigorous risk analysis on these items can effectively prioritize maintenance efforts.

KOC decided a quantitative approach to risk would work best for them, with the results of risk analysis for any given pipeline segment producing data that can be compared and benchmarked against all other sections, regardless of their product or other conditions. KOC chose C-FER Technologies' Piramid software as the risk analysis engine, creating a need for specialized tools to:

• Extract data from the pipeline database to be load-ready for risk analysis.

• Format and import risk results back into the APDM database.

• Produce flexible and comprehensive reports and views of the data.

The following section outlines the steps taken and considerations met for achieving TPIMS objectives. The project's scope has changed over the past 5 years and will most likely continue to do so. As new information becomes available and different technical challenges arise, it is imperative to continue updating procedures and finding new and innovative means to adapt.

Implementation

• Phase 1—Initial data assessment. The first step included having existing archive documents scanned and the information put into tabular form. Collecting and organizing data in a database as opposed to spread sheets or other media ensure a level of referential integrity (text stored as text, numbers stored as numbers, dates stored as dates, etc.). Collecting and storing data in a pre-assessment database (PADB) allowed normalizing the wide variety of sources and levels of completeness so that standardized query and comparison could be done on any applicable section.

• Phase 2—Data model, GIS design. KOC chose APDM and through the duration of the project has evolved its use from Version 3 to 4, and most recently to Version 5.0.

Determining a method for organizing the data followed a preliminary examination of them, with the decision made to adopt a client-server based, dual-application suite of software modules.

The first, Pipeline System Explorer, could be used by numerous users (at present more than 70 active licenses) and used as a "viewer" application for high-level users. The companion product consisted of several modules used to catalog and compartmentalize the pipeline sections into individual or combined workspaces for more comprehensive assessments. These include a map view, database view, profile-chart view, print-layout view, and others.

Tools provided allow direct editing of the APDM database with a complete audit trail, the overlay of data in map views (aerial imagery, base map) and alignment of data from an endless variety of sources. The results of ILI and other surveys can also update the spatial location of pipelines.

Formatting and normalizing data for entry into an industrial-sized database proved to be the most difficult task of all in implementing TPIMS. Each dataset required scrubbing for consistency, as well as ensuring its placement in the correct location.

• Phase 3—Preassessment. A study performed near the beginning of the project determined the method of inspection for each pipeline segment. KOC decided that of the total 359 lines, 75 were suitable for in-line inspection, with the remaining 284 considered unpiggable. KOC then selected 261 of the nonpiggable lines on which to apply National Association of Corrosion Engineers (NACE) external corrosion direct-assessment (ECDA) techniques, which KOC decided would be the most effective way to evaluate and prioritize pipeline sections in the absence of any other available information.

• Phase 4—Indirect inspection, direct examination. KOC contracted indirect inspection (iDI) out to another company to provide for input into the TPIMS project. Indirect-inspection methods used included close-interval potential survey (CIPS) and direct current voltage gradient (DCVG) to find areas suspected of substandard cathodic protection.

Direct examination (DEx) was the next step in verifying these findings, achieved by exposing the pipeline, removing the coating, and inspecting entire sections of pipe by hand (Fig. 2).

.All iDI reports reside in the TPIMS document management system for each line. Each individual line's TPIMS projects are viewable and include links to all reports and data collected for that pipeline segment.

Achieving cooperation between database reliability and report results provided by the DEx field crews required development of yet another database standard and set of procedures to normalize and standardize the data for use by TPIMS's many components.

• Phase 5—GPS mapping. This phase started before the TPIMS initiative but became the benchmark for all data alignment and integration in the future. The start and end of all pipeline sections were somewhat known but not yet consolidated, categorized, or named by any standard system. Knowledge of the pipeline center line routes in-between was minimal, at best.

KOC over-the-line surveyed the entire length of the pipeline system (more than 3,000 km) with submeter GPS units to collect all identifiable feature locations. Collecting these points and segments used standardized data dictionaries to classify them for eventual load into TPIMS. Extracted centerline route information provided a baseline for generating a network in the database.

• Phase 6—ILI, direct examination. Running in-line mapping tools with an inertial navigation system (INS) has further mapped more than 50 pipelines. A range of standalone-INS and combination INS-MFL-caliper-deformation-ultrasonic technologies have generated an accurate, four-dimensional centerline for the available pipeline.

Inertial navigation technology, combined with odometer measurements from in-line inspection tools, produces latitude, longitude, elevation, and in-line distance measurement for a continuous trajectory as well as for all identifiable features along the pipeline route. Beyond being much more accurate, these generate an output more conducive to data alignment and integration.

Many of the features mapped in the aboveground DGPS survey proved to be correlated with features reported from the ILI surveys. Accepting input from any type of ILI data and from multiple vendors required development of another set of processes and procedures.

Further DEx surveys could now confirm results of the ILI surveys. Confirmations compared the initial centerline position, evidence of coating condition, and depth of external corrosion metal loss.

• Phase 7—Risk assessment. Reaching the risk-assessment phase is when the efforts made at centralizing the data began to pay off. A risk assessment is required to fulfill numerous industry standards for both gas and liquid pipeline systems. An initial risk assessment performed in 2007 included no ILI data. A few lines had been inspected with various ILI technologies, but data lay outside the model applied at that time. Incorporated results become part of future inspection plans.

• Phase 8—Ongoing data integration, updating. Updating the database continually became the focus on the baseline. All repair information, cutouts, sleeves, recoats, etc., required cataloging and inputting to their locations.

KOC performed more INS-based ILI surveys, remediated pipelines, and continued to upload all applicable data to the central database. More information became available as a result of the DEx surveys and more involvement from the increased number of users who now interacted with the system, providing input towards correcting information that may have originally been assumed accurate but was now proven otherwise.

• Phase 9—Reassessments. KOC performed a subsequent risk analysis of the entire system in early 2010, including a reliability-based RISK analysis from C-FER for lines inspected with an ILI survey (in addition to the historical-based model run on all other lines). The latest results show a data-quality deficiency in the past. Comparing the baseline risk study with the current risk study showed an expected improvement in results as more complete data had been acquired and included.

Comparisons can continue on a line-by-line basis from this point forward. Results will also become part of future ILI and DEx planning as part of the company's overall integrity-management plan. One weakness in the current data set has already shown the need for procurement of additional data, especially within populated areas.

• Phase 10—Ongoing document and data management. All items initially considered have now lived though one full assessment life-cycle. Data files, ILI surveys, and risk values as well as resulting reports from all of these now have a place and procedure for their inclusion in the system.

Benefits

The TPIMS project made it possible to integrate and manage data from various sources by conducting all modes of integrity assessment including ILI, direct assessment, and hydrostatic testing as well as structuring a comprehensive risk assessment and decision support mechanism. TPIMS resulted in more efficient planning and use of data not readily available in the past. Relevant information is now at the fingertips of users in all areas of KOC, and maintenance will only get easier as time goes on.

The authorsMore Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com