Mastering LNG tank-pressure duality improves operations

Maksym Kulitsa

FSRU consultant

Odessa, Ukraine

David A. Wood

DWA Energy Ltd.

Lincoln, UK

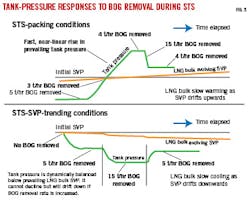

Understanding and modelling LNG tank-pressure duality, as well as general awareness of the phenomenon, is essential for both effective floating storage and regasification unit (FSRU) and shore-based terminal operations. Observations of ship-to-ship (STS) transfers of LNG to FSRU reveal a duality in the way tank pressures respond, sometimes allowing tank pressure to rise rapidly and other times holding pressure at stable levels. These behaviors are determined by the saturated vapor pressure (SVP) of the LNG bulk, surface film, and vapor space conditions, together with the prevailing tank operating processes. Accounting for pressure-duality principles helps improve FSRU and shore-based tank management and decision making, reducing boil-off gas (BOG) consumption and saving the cargo’s commercial benefit.

Empirical observations reveal a duality in FSRU tank-pressure behavior that in overpressured conditions allows tank pressure to rise rapidly. In under-pressured conditions, tank pressure stabilizes at certain levels and inhibits reduction below those levels. Understanding these principles and governance of actual tank pressure by its relation to LNG SVP plays a crucial role in effective handling of LNG to minimize cargo waste.

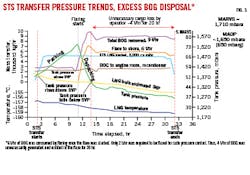

The gas combustion unit (GCU) and steam dump (SD) act as safety equipment to treat excess BOG. But inefficient and outdated operator practices lead to more gas being consumed than is justified for safety reasons. Much of the unnecessary gas losses occur during cargo transfers. They are common for LNG carriers (LNGC) as well as an inherent part of FSRU operations. A technological step forward for FSRU BOG handling equipment has occurred in recent years that can deal with BOG efficiently if good operating practices are applied.

This article explains the processes involved in determining optimal FSRU tank pressure trends and how they evolve during ship-to-ship (STS) transfers and how tank pressure trends should be interpreted and responded to, focusing on LNG pressure-duality behavior in large shore-based and FSRU tanks. The large quantity of LNG in such tanks has a key bearing on the pressure trends they display, and a simple reactive approach is not sufficient to achieve the best commercial performance.

Large containment tanks

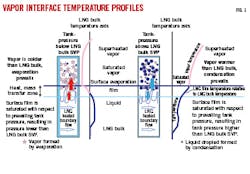

Changes to the physical properties of LNG in containment tanks are controlled by the physical laws applicable to any condensed cryogenic gas in a closed system when the liquid phase is in contact with its vapor phase. Due to the large scale of such tanks, the processes at work are complex and governed by layers formed in the LNG mass. A thin LNG surface evaporation film exists at the interface between the liquid and vapor phases (Fig. 1). It controls heat and mass exchange between the vapor and the LNG bulk. Convection currents within the LNG bulk are perpetuated by heat ingress through the walls and bottom of the tank. In simple terms, LNG is heated on the walls and floats up to the surface where it gives off a BOG flash via the LNG surface film (the Hashemi-Wesson layer) that is always in thermodynamic equilibrium with actual tank pressure. The LNG bulk is ultimately governing tank pressure but through the prism of the surface film. This causes the prevailing tank pressure most of time to be quite different from SVP of the LNG bulk.

The LNG surface film possesses key properties that affect tank pressure. The film always strives to be in dynamic equilibrium with actual tank pressure and rapidly responds to pressure changes. It manages to achieve dynamic equilibrium rapidly compared with responses in the LNG bulk, which occur relatively slowly. The film’s SVP adjusts rapidly to changing tank conditions, reaching equilibrium after any pressure change, typically within about 30 min. Conditions of the LNG film, actual tank pressure, and LNG bulk are all interrelated. Change in one ultimately leads to changes in the other two. If the LNG bulk changes its heat content then tank pressure adapts to the change of temperature through the conduit of the LNG film.

When tank pressure equals SVP of the LNG bulk the film has the same SVP and temperature and is in broad equilibrium with the prevailing tank pressure. That is the ultimate state towards which the whole system tends when no external processes are ongoing. But an operating tank is almost always subject to external influences (e.g., BOG removal, reloading LNG, removal of LNG to supply send-out gas, etc.). Operating tanks, therefore, exist in a dynamic state of equilibrium, only occasionally achieving broad equilibrium briefly in a transitory manner. Broad equilibrium is used here to refer to the special dynamic state between LNG bulk, LNG film, and actual tank pressure at a specific moment in time.

LNG film acts as a buffer zone between LNG bulk and the vapor space when film SVP, bulk LNG SVP, and tank pressure are equal. It regulates mass exchange through evaporation and condensation of vapor. It operates as a constraint or porous medium in both directions, enabling mass exchange with different effects.

- Overpressure. When tank pressure, for whatever reason, becomes higher than the SVP of the LNG bulk, condensation prevails over evaporation at the surface film. Excess pressure encourages vapor molecules back into the liquid state through the film’s surface. The resulting latent heat of condensation then warms the film, causing the film’s SVP to rise following an increase of vapor space pressure.

The mass of the film is small, allowing it to warm up rapidly (above the temperature of the LNG bulk) and slowing effective mass exchange between LNG bulk and film. This leads to a compression of tank vapor space and a linear pressure increase. The warmed film acts broadly as a blanket that prevents a large mass of vapor absorption back into the LNG. In such conditions the heat that enters the LNG bulk is not released, as no excess evaporation can occur through the film. Thus, the LNG bulk absorbs all heat ingress (from tank walls) and its bulk temperature slowly rises. This state is associated with two activities: high-rate STS transfers of new LNG into a tank while BOG removal is unable to compensate for vapor space volume decrease or low-duty compressor recycles of hot vapors back into the tank at low regasification rates.

- Underpressure. When tank pressure falls below SVP of the LNG bulk, for whatever reason, the film acts as a mesh that delays, but does not halt, evaporation velocity. In such conditions, evaporation prevails over condensation. The LNG film is rapidly cooled by the latent heat of vaporization as heat is taken away by evaporated vapor molecules.

This process lowers the LNG film’s SVP, and tank pressure drops to be in equilibrium with the film. But mass and heat exchange between LNG bulk and film is enhanced as soon as tank pressure falls below SVP of the LNG bulk. This is because the film is colder than the warmer LNG bulk and situated above it. Evaporation rate increases the more tank pressure is forced to fall below the LNG bulk’s SVP.

LNG bulk resists and inhibits tank pressure falling much below the bulk’s SVP. It becomes dynamically steady at a certain pressure level below the SVP of the LNG bulk. This dynamically floating pressure below the SVP of the LNG bulk is defined by the amount of BOG removed from tank. Increasing BOG removal enhances evaporation from the film by orders of magnitude. But further attempts to lower tank pressure by increasing BOG removal tend to be ineffective.

Empirical observations on FSRU indicate that actual tank pressure may be dynamically held floating below the SVP of LNG bulk by 10-50 mbar at boil-off evacuation rates of 2-12 tons/hr, respectively. This state is typical of FSRU tanks during regasification, while they are not being impacted by high-rate STS transfers.

Sloshing or LNG rollover events can destroy or severely disrupt the surface film mechanically. The film re-establishes itself within a short time once the disrupting forces cease. A destroyed or disrupted surface film has a great impact on tank pressure, as the LNG bulk mass exists with no constraining layer (surface film) between it and the vapor space. This results in the following related effects as tank pressure approximates SVP of the LNG bulk:

- Film broken when tank pressure is higher than LNG bulk SVP. Liquid at the surface tends to reach an equilibrium state with tank pressure. This drastically enhances condensation due to the subcooled state of the LNG on surface. Consequently, tank pressure declines as some vapor mass is absorbed into the LNG via condensation. Enhanced condensation rates continue until a film is self-restored and reaches equilibrium with reduced tank pressure. If the film is disrupted for long enough, tank pressure equilibrates with the LNG bulk’s SVP.

- Film broken when tank pressure is lower than LNG bulk SVP. Liquid at the surface tends to reach an equilibrium state with tank pressure. This drastically enhances evaporation, causing tank pressure to rise rapidly towards SVP of the LNG bulk due to the vapor mass emission caused by the LNG’s superheated surface state. Tank pressure rises rapidly to match SVP of LNG bulk. Enhanced evaporation rates continue until a film is self-restored, reestablishing its mesh effect. This is the case with rollover events. Evaporation rate and tank pressure increase very rapidly. Again, if the film is disrupted for long enough, tank pressure equilibrates with the LNG bulk’s SVP.

The LNG surface film is easily disrupted, e.g., by agitation during tank top filling. Sloshing in tanks when LNGC are sailing in moderate seas will also destroy the surface film leading to a rise in tank pressure towards the LNG bulk SVP. Once the sea calms, tank pressure typically returns rapidly to its original value as the surface film reforms.

Without the LNG surface film’s properties, tank pressure would continuously track LNG bulk SVP, regardless of which operations were conducted. But this is not what is observed in practice, due to the LNG bulk’s large mass, and what occurs instead needs to be accounted for.

The LNG film’s effects on tank pressure, and vice versa, are dynamic and of practical significance during operations. They remain effective as long as external processes persist but, once these processes cease the system rapidly returns to a broad equilibrium state, tank pressure equilibrating with the LNG bulk’s SVP. Equilibrium conditions exist just near the LNG surface. Vapor some distance above the LNG surface gradually warms due to heat ingress and volumetrically expands.

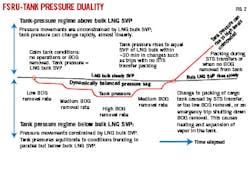

Due to the large size of LNG mass in typical LNG tanks, the process occurs in practice in a more complex way than described as a basic physical concept. This is because LNG exists dynamically and has multiple transition states and stable points. The three components (LNG bulk, surface film, and vapor space) constantly interact with one another. The film and vapor space rapidly influence one another and settle into equilibrium after a short transition state whenever changes occur to tank processes (e.g., increase in BOG offtake, reduced STS transfer rates, etc.). The LNG bulk also influences the film-vapor phase relationship, making it so that the actual tank pressure generally does not match the LNG bulk’s SVP at any given moment. SVP of the LNG bulk acts as a demarcation line defining two distinct operational states of vapor-liquid system behavior that typically persist in the LNG storage space.

A third common state occurs occasionally, i.e., when actual tank pressure equals the SVP of the LNG bulk. This broad equilibrium state between the LNG bulk, film, and vapor states is a brief transient condition, occurring between the other two persistent and dynamic states.

The phenomena described are referred to as tank-pressure duality (Fig. 2) and have significant implications for managing operations of both FSRU and shore-based tanks.

Tank pressure duality

There are practical applications of duality in the behavior of tank pressure for tanks containing LNG. Typically, operators tend to lower tank pressure by increasing BOG removal rates (in GCU or SD) during STS transfers. Such actions, however, do not account for tank pressure being inhibited from descending much below LNG bulk’s SVP, irrespective of the magnitude of BOG removal. At specific moments it appears that whatever BOG quantities are evacuated from the tank, tank pressure remains broadly stable and does not broadly reduce further. This appearance leads to large cargo loss with negligible benefits in terms of lowering tank pressure (Fig. 3).

Burning gas in the GCU or SD before an STS transfer to preempt tank pressure increase in such conditions is futile, unnecessary, and wasteful since just controlling pressure during the transfer is more effective. Understanding tank pressure duality helps operators make appropriate and meaningful commercial decisions regarding effective tank pressure control. It also helps forecast likely tank pressure trends during STS transfers, leading to more rational decisions regarding when to burn BOG in the GCU or SD and avoiding waste of cargo.

STS tank pressure trends

Pressure change tendencies and outcomes differentiate common STS transfer patterns. Three key events determine tank-pressure behavior:

- STS transferred cargoes mix with the existing LNG bulk (the heel).

- STS transferred cargoes do not mix but form a distinct stratified layer separate from the heel.

- Physical changes in the vapor-space state that emerge during STS transfers depending on the volume of BOG removed from tank, determining whether significant compression of the vapor space occurs, or not.

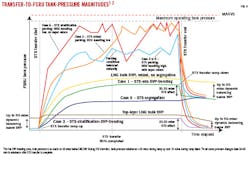

If the BOG volume removed from the tank compensates for the piston effect of LNG entering the tank, then SVP-trending conditions prevail. Tank pressure persists dynamically just below the evolving SVP of the LNG bulk. On the other hand, if physical compression (or packing) of the vapor space takes place tank pressure tends to rise rapidly, like being compressed in a cylinder. Also, the LNG bulk’s SVP is likely to gradually change during such operations.

The LNG bulk’s SVP is critical as it represents a demarcation line between SVP trending and packing. Depending on the operational conditions and operator’s responses to those conditions, the SVP demarcation line may be crossed, at which point packing conditions would change to SVP trending conditions, or vice versa. LNG heel densities determine whether the STS transfer outcome is a single homogeneous LNG layer or if stratification emerges and persists until a rollover occurs.

Fig. 4 shows several possible tank pressure behaviors:

- Case 1: STS mix with SVP-trending conditions.

- Case 2: STS mix with packing conditions.

- Case 3: STS stratification with SVP trending conditions.

- Case 4: STS stratification with packing conditions.

- Case 5: STS segregation conditions (various combinations of those in different tanks of an FSRU at the same time).

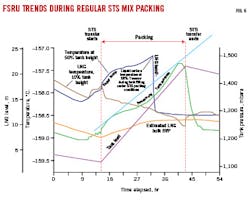

These distinct tank pressure conditions can exist during all FSRU operations, not only during STS transfers. It is important for tank operators to be aware of whether packing or SVP trending conditions prevail, and these are relatively easy to distinguish (Fig. 5).

Surface condensation

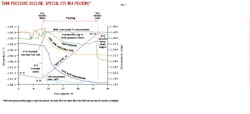

Increased condensation at the LNG surface film always occurs when tank packing conditions prevail. But when the surface LNG film is disrupted or destroyed tank pressure trends vary anywhere from non-linear rising to falling. Such conditions can occur during STS transfer under mixing conditions when a new light bottom-filled cargo is introduced into a heavy LNG heel. The tank pressure trend that emerges (Fig. 6) show a characteristic sag compared with the linear tank pressure rising trends associated with STS stratification and packing. Note that the term “tank pressure sag” as used here can mean either a non-linear upward pressure trend with a convex-downwards shape or a pressure trend held above and near the SVP of the LNG bulk in tank overpressure conditions.

In conditions under which the LNG surface film is continuously destroyed, tank pressure may be dominated by enhanced condensation at the LNG surface for an extended period (Fig. 7), leading to special case of sag in which pressure does not rise but stabilizes dynamically at a certain value despite existing overpressure conditions.

Practical operation

Operating FSRU and large land-based regasification plants requires deeper knowledge and understanding of LNG tank pressure processes compared with conditions typically prevailing in LNGC used for marine LNG transportation. Knowledge and understanding of pressure-duality assists in making effective tank-pressure control decisions and avoiding unnecessary cargo waste in GCU-SD or flaring ashore. Reducing such waste over an operating year can yield significant long-term commercial benefits.

Exploiting pressure-duality benefits is particularly effective for FSRU converted from LNGC, because their tank pressure rating is not 700 mbarg (that of most new-build FSRU) but typically just 250 mbarg. Tanks of such FSRU conversions cannot be operated efficiently using strategies applicable to 700-mbarg tanks. They require operational attention to detail and careful decision making to optimize tank pressure control, performance, and safety. STS transfer operations are conducted offshore and tank pressures need to be carefully managed and coordinated on both vessels.

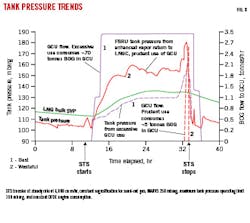

Controlling tank pressure within a strategically established range of packing conditions can minimize FSRU cargo waste (Fig. 8). The GCU or SD would then be used intermittently and sparingly, for immediate safety reasons, as tank pressure approached maximum operating limits. GCU-SD use should be focused on essential safety-related responses rather than unjustified and wasteful extended use as a precautionary measure. It is possible to operate safely and efficiently at the same time.

During STS transfers LNGC tank pressure should not be allowed to reduce from its recorded value on arrival at the FSRU. Allowing such pressure reduction would provoke increased evaporation in LNGC tanks and reduce BOG returns from the FSRU, likely leading to more BOG waste on the FSRU side of the transfer to control tank pressures. There is a desire to perform STS transfers at a faster rate than could be achieved a decade ago. Increased transfer rates, however, tend to have a detrimental impact on FSRU tank pressure and therefore require even more careful tank pressure decision making.

Sudden tank pressure rises during LNG cargo rollovers can also be explained in terms of pressure duality and managed more effectively when such considerations are considered. Warm LNG bulk emerges at the LNG surface during a rollover, destroying the existing LNG surface film. Tank pressure rises rapidly as a result towards the new, higher SVP of the warm LNG emerging at the surface. Pressure duality principles provide useful insight into understanding how and when tank pressure changes occur in relation to operations, explaining the evolution and fluctuation of tank pressure trends. Such principles should be standard knowledge for LNGC and FSRU operators and part of their formal training.

Bibliography

Kulitsa, M. and Wood, D.A., “LNG Cargo Handling (Part 1): New approach improves ship-to-ship LNG transfers,” Oil & Gas Journal, Vol. 115, No. 11, Nov. 6, 2017, pp. 56-60.

Kulitsa, M. and Wood, D.A., “LNG Cargo Handling (Conclusion): Tandem pressures between ships during STS transfers cuts gas losses,” Oil & Gas Journal, Vol. 115, No. 12, Dec. 4, 2017, pp. 65-70.

Kulitsa, M., and Wood, D.A., “Duality in LNG tank-pressure behavior and its relevance for ship-to-ship transfers to floating storage and regasification units,” Advances in Geo-Energy Research, Vol. 4, No. 1, March 2020, pp. 54-76.

The authors

Maksym Kulitsa ([email protected]) is an FSRU on-board operator with more than 8 years’ experience of different regas systems on different FSRU terminals. Since FSRU is a relatively new direction in LNG industry, Maksym took a private interest and initiative in optimizing FSRU-related operations to achieve its best efficiency as particular ship designs and operating conditions allow.

David A. Wood ([email protected]) is principal consultant of DWA Energy Ltd., UK. He has more than 40 years of international oil and gas experience spanning project operations, technical evaluations, research, contract negotiations, senior corporate management, and expert witness services.