Whitewash UV coatings preserved stockpiled Keystone XL pipes

Keith E. W. Coulson

James Ferguson

David Milmine

TC Energy

Calgary

Even after nearly a decade, the use of whitewash ultraviolet (UV) protective coatings proved to be extremely successful in preserving and retaining the original dry film thickness (DFT) of fusion bond epoxy (FBE) coating. Apart from its elasticity, UV protective coatings conserved many of the physical characteristics of the underlaying FBE coating. A more frequent retention and application of non-faded whitewash coating to UV-exposed coatings could have also maintained the FBE coating’s elastic characteristics.

TC Energy initiated an assessment program on stockpiled coating and pipe as part of the Keystone XL (KXL) project refurbishment program for FBE coated pipe that has been stored for up to 9 years. Pipe originally fabricated and coated for the KXL project was stored at a variety of sites throughout the US and Canada. As part of the assessment program, pipe being held at Little Rock, Ark., was studied to determine the influence of UV exposure on the FBE coating’s integrity. Previous studies of exposed weathering of FBE coating identified that UV exposure could have a serious deleterious effect on the inherent physical properties of the coating (OGJ, Apr. 16, 2001, p. 58).1 This was especially true regarding loss of coating thickness, loss of gloss, and reduced flexibility.

Most of the pipe stored in the external layers of the stockpiles was coated with a whitewash acrylic resin coating to reduce or eliminate UV degradation. The inside piping at the stockpiles was not protected with the acrylic coating, as it was determined that the overlaying whitewashed coated pipe would eliminate UV degradation’s influence. The only exception was the overhanging pipe ends.

The non-protected FBE coatings exposed to UV for as long as 9 years completely failed to retain their original properties and attributes. Conversely, coatings that were completely protected from any UV exposure possessed all their original thickness and physical traits.

This article describes the short- and medium-term testing program developed to assess the integrity of the coating at Little Rock and determine its fitness for purpose as a pipeline coating.

Project background

TC Energy has nearly 5,000 km of liquid pipeline system shipping more than 2 billion b/d. It was as part of this liquids system that the KXL project was designed. The project comprised 530 km in Canada and slightly more than 1,400 km of pipeline to connect US refining hubs in Illinois, Oklahoma, and the Gulf Coast of Texas. KXL pipe was procured, manufactured, and coated in the years 2009, 2010, and 2011. The pipe was stockpiled in large quantities at sites close to the pipeline right-of-way. Once stockpiled, most of the pipe remained stationary until an inspection and remediation program in August 2018. At intermittent periods, a layer of UV-resistant white acrylic water-based paint was applied to protect the FBE coating from incessant exposure to the environment.

This article details the engineering assessment program carried out to ascertain the exact level of coating integrity of pipes with the applied UV-resistant paint and also evaluates any injurious effects of environmental exposure on pipe with little or no UV exposure.

UV exposure vs. FBE

When exposed to ultraviolet rays, FBE coatings undergo polymer degradation, commonly referred to as chalking. This phenomenon is common to all FBE coatings, which are primarily designed only for below ground service. If undisrupted, this layer of chalked FBE will protect the underlaying FBE and enable the coating to retain most of its original properties.2 If this protective layer of chalked coating is removed by rain, wind, or intense periods of UV exposure, however, the new surface starts to suffer from the repeated process of chalking. As breakdown and delamination of the outside layers continue, a noticeable reduction in coating thickness occurs.

Coating thickness reduction could average 0.40-1.57 mils (10-40 µm)/year. The degree and effects of chalking depend on the following factors:

- Susceptibility of the FBE’s formulation to UV breakdown.

- Amount of exposure to UV. For example, the 12 o’clock position on a pipe generally suffers more coating breakdown than the less-exposed 3 or 6 o’clock positions.

- Intensity and duration of direct exposure to the elements. For instance, UV intensity in the southern US would be far greater than that in Canada, leading to quicker breakdown and chalking.3

- Availability of water through rain and morning dew.

Previous studies also demonstrated that when exhibiting chalking and reduced coating thickness, some FBE coatings would show reduced resistance to cathodic disbondment (OGJ, Mar. 10, 1986, p. 47). All FBE coatings struggle to retain their original flexibility when examined in accordance with the Canadian Standards Association (CSA) Z245.20 cold temperature flexibility test method.4 An aesthetic change of gloss and chalking is accompanied by embrittlement of the coating as exhibited by loss of adhesion through dry adhesion testing (DAT) and reduction of flexibility performance. Any reduction in the interaction of UV and the coating via tarping, whitewashing, or any other means would therefore be beneficial in reducing or eliminating UV damage to the polymeric structure of the FBE.

Pipe data

Evaluation used specific pipe sections representative of the pipe stocks at Little Rock. Pipe sampled was representative as follows:

- 36-in. OD × 0.465-in. WT., API Spec 5L (44th Edition), PSL 2 PSL Grade X70 SAWH pipe, coated externally with FBE to the requirements of CSA Z245.20 System 1A4 but noted as without any evidence of the application of an acrylic UV deterioration mitigation system (herein referred to as whitewash).

- 36-in. OD × 0.465-in. WT., API Spec 5L (44th Edition), PSL 2 PSL Grade X70 SAWH pipe coated externally with FBE to the requirements of CSA Z245.20 System 1A4 and exhibiting the presence of a post coating applied whitewashed UV deterioration mitigation acrylic paint on all exposed areas exclusive of the pipe ends.

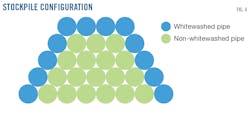

Piping was generally stored four or five high with 19 mm ropes used as separators (Fig. 1).

Whitewashed pipe in storage was estimated to constitute at least 20% of the roughly 24,000 joints of 80-ft (24 m) pipe stored at Little Rock. This pipe had been stored for 18-24 months before application of the acrylic whitewash. Whitewash UV protective coating was reapplied once after a period of 4-5 years. In all cases, the last few feet at both ends were left bare, so as not to overcoat the stencil and pipe identification markings on each pipe end. Even after replenishing, however, the whitewash acrylic resin coating appeared to have faded (Fig. 2). This fading potentially denoted that the effectiveness of the whitewash to resist UV degradation had been reduced during UV exposure of 4-5 years.

Protocol

Refurbishment assessment sought, firstly, to determine the effects that weathering had on the pipe underneath the faded whitewash and ascertain the quality of the FBE coating. It also sought to establish a benchmark performance criterion for the coating on pipe stored internally in the stockpile and not exposed to UV.

An inspection and test plan (ITP) assessed pipe-coating integrity. The examination included:

- FBE coated with whitewash acrylic UV protective coatings.

- FBE coating from pipes stored in the internal segments of the stockpile not exposed to UV (Fig. 3).

- FBE coating on the pipe ends or overhanging pipe that was not whitewashed coating but was exposed to some UV.

The ITP stipulated the following testing activities:

- Documentation of pipe numbers and correlation to location in the stockpile for selected pipe piles.

- Performance of dry film thickness (DFT) on selected pipe. Frequency and location on pipe to be determined and documented, for example 12 and 6 o’clock positions.

- Performance of DAT in accordance with ISO 21809-3: Annex Q: Adhesion Test.5

- Performance of holiday detection inspection on selected pipes.

- Submission of selected pipe for laboratory testing at the Welspun Coating Plant laboratories in Little Rock, Ark., and Partech Laboratories in Pearland, Tex.

Objective

The program sought to:

- Enumerate the correlation between DFT and dry adhesion testing (DAT) techniques with the integrity assessment evaluations stipulated by the Canadian Standards Association in CSA Z245.20-14.6.

- Conduct a series of laboratory tests, establishing to regulators that dry adhesion and dry thickness testing does quantify the quality of FBE coatings being held at the stockpiles.

- Confirm the conclusion that non-UV-exposed FBE coating was still fit for purpose as a below ground anti-corrosion mechanism.

Field assessment

Initially, 12 joints of pipe that had been whitewashed and stored on the outside layers of the stock piles were removed. These 12 pipe joints, along with three joints from the interior of the stockpiles, were assessed as specified in the ITP defined in the protocol for assessment.

Fig. 4 illustrates configuration of the whitewashed and non-whitewashed pipe in the stockpiles. All pipes were identified via stenciling or barcodes.

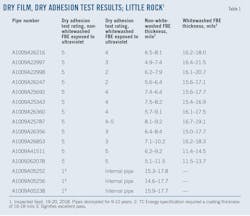

Table 1 shows the results of DAT and DFT testing. With few exceptions, FBE coating on the piping that was whitewashed still had acceptable coating thickness measurements. TC Energy‘s coating specification required 16-18 mils (406-457 µm) of FBE coating during manufacture. A range of 15.93-18.45 mils (404-468 µm) was recorded on the whitewashed coating, generally inside the range originally stipulated.

The DAT’s performed on the white washed pipes, however, no longer consistently met the minimum requirements expected of this coating. Table 1 shows that eight of the 10 test joints failed to attain acceptable DAT ratings of 1 or 2. But the pipe that was not whitewashed and was exposed to UV continuously during storage, exhibited complete failure under DAT evaluation.

Fig. 5 offers an example of the poor DAT results on whitewashed pipe. The UV-exposed non-whitewashed FBE coating also had a remaining coating thickness of only 6.4-8.5 mils (162-215 µm). Coating loss of about 1 mil (25.4 µm)/year of UV exposure had occurred. This deterioration was within the accepted industry range of 0.40.-1.57 mils (10-40 µm)/year of FBE coating loss when exposed continuously to UV.2

Initial testing on non-whitewashed coated pipe stored in the interior of the stock piles indicated the joints were clearly fit for purpose (Table 1).

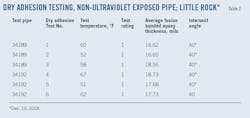

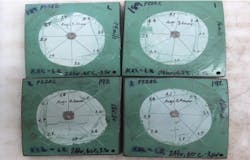

Two additional non-whitewashed joints from the interior of the stockpiles were more comprehensively examined at the stockpile site. Table 2 provides results of that assessment. Each joint was quarantined and tested at three separate locations along each pipe. At each location DAT and DFT testing was completed at the 12, 3, 6 and 9 o’clock positions. All coating on these pipes provided excellent results. DAT test results were of the highest standard, each test producing a prefect rating of 1 (Fig. 6). Average coating thickness also was within range at 17.7 mils (450 µm), comparable with original factory recorded average thickness of 17 mils (430 µm).

Further testing focused on two test rings from each of the two pipes. Each test ring was big enough to allow for specimen preparation and to perform the range of applicable tests according to Table 4 of CSA Z 245.20-14 and Clause 7.3.3.3 of TC Energy specification TES-CO-FBE-GL Revision 09. One test ring from each pipe was shipped to Partech Labs in Pearland, Tex., and the other test ring from each pipe remained for testing at the Welspun coating laboratory in Little Rock.

Laboratory assessment

An assessment according to CSA Z245.20-14 Table 3 criteria was conducted for the following properties:

- 2.5° flexibility testing at −30° C.

- 24-hr cathodic disbondment test at 3.5 V and 65° C.

- 24-hr water soak adhesion test at 75° C.

- Additional 1.5° flexibility at −30° C. (from three specimens, in accordance to Clause 7.3.3.3 of TES-CO-FBE-GL Revision 09) was included to check for any stress, strain, or pigment migration markings.

The use of differential scanning calorimetry was not considered for this program due to the deleterious moisture absorption effects on the interpretation of these thermal tests (OGJ, Feb. 24, 1986, p. 63).

Non-whitewashed pipe ends were deemed total failures (Fig. 7). The whitewash protected coatings fared much better, with cathodic disbondment testing (CDT) results of about 5 mm and water soak adhesion ratings of 2. The whitewash FBE coating, however, demonstrated serious deterioration in its flexibility performance (Fig. 8).

Flexibility tests were all deemed failures on both the UV-exposed pipe ends and whitewashed piping. The testing degree/pipe diameter length of pipe was reduced from 2.5° to 2° and then 1.0°, all of which demonstrated similar cracking within the coating (Fig. 8).

Laboratory test results of non-ultraviolet exposed pipe were excellent (Tables 3-4), demonstrating that coating not exposed to UV or weathering was still totally fit for purpose and retained most of the properties exhibited at production. Figs. 9-10 show the excellent CDT performance of this coating.

All non-whitewashed pipe exposed to continuous UV at Little Rock, such as pipe ends and stenciled areas, were no longer fit for purpose. Coating loss was about 1 mil (25.4 µm)/year.

Coated pipe tested from the internal portions of the stockpile and not exposed to weathering was deemed totally fit for purpose, passing all required CSA tests. The only exceptions were pipe ends that may have been exposed to UV due to overhang in the stockpile.

All whitewashed coating exhibited good retention of coating thickness and cathodic disbondment and hot water soak adhesion characteristics. But the flexibility of the underlaying FBE was affected to the point that the coating was no long acceptable. This depression of coating flexibility levels could have been caused by the combination of moisture absorption and elevated temperatures. When the faded whitewash coating no longer acted as a reflective mechanism, the surface temperature of the coating increased during prolonged periods of exposure to intense sunlight. Future study is required to understand if pigment migration, plasticizer effects, or mechanical alternating due to moisture absorption were the actual root causes of the phenomenon, whereby only the flexibility properties of the coating were so badly affected.

The whitewashed protective coating was originally applied 18-24 months after the pipe was coated. In the intervening years, there was only one other application of the whitewash coating. If the whitewash coatings had been applied on a more regular basis—for example, every 2 years—deterioration of the coatings’ flexibility may have been prevented.

References

- Coulson, K.E.W. and Temple, D.G., “An Independent Laboratory Evaluation of External Pipeline Coatings,” 5th International Conference on Internal and External Protection of Pipes, Innsbruck, Austria, Oct. 25-27, 1983.

- Kehr, J.A., “Fusion Bonded Epoxy, A Foundation for Pipeline Corrosion,” NACE International, Houston, Tex., 2003.

- Liley, J.B. and McKenzie, R.L., “Where on Earth has the highest UV?” National Institute of Water and Atmospheric Research, Lauder, Central Otago, New Zealand, 2006.

- Canadian Standards Association, “Plant-Applied External Fusion Bond Epoxy Coating for Steel Pipe,” CSA Z245.20-14, Toronto, Canada.

- International Standards Organization ISO 21809-3, “Petroleum and natural Gas Industries – external Coatings for Buried or submerged Pipelines Used in Pipeline Transportation Systems- Part 3: Field Joint Coatings: Annex Q: Adhesion Test – Resistance to Removal,” ISO Switzerland, Mar. 1, 2016.

Acknowledgements

The authors would like to acknowledge the contribution of Snehal M. Patel, Vice President, Welspun Tubular LLC and P.N. Mahida, Associate VP Quality and Technical Services, at Welspun Tubular LLC Little Rock, to the success of this program.

Thanks also to Casey Bajnok of TC Energy for supplying background details of the project and to Heather Traub of TC Energy for graphic and editorial support.

The authors

Keith E. W. Coulson ([email protected]) is a technical consultant with TC Energy, Calgary. He was previously the technical vice-president of Jotun, Norway, after spending 22 years at TC Energy as pipeline corrosion specialist. Keith was educated at the University of Swansea, Wales, and the University of Aston, England, where he attained his master’s degree. He has more than 40 years of experience in the oil and gas industry and has authored in excess of 30 published technical papers on pipeline integrity, stress corrosion cracking, quality management, and pipeline materials. He is a Registered Professional Engineer in Alberta, a Fellow of the Institute of Corrosion (UK) and a registered NACE Corrosion Specialist. He is also licensed as a European Engineer (Eur Ing). Keith is the former head of the Canadian delegation to the International Standards Organization (ISO) on pipeline materials and past chair of the Canadian Standards Association (CSA) on pipeline coatings.

James Ferguson is a director with TC Energy, Calgary. He has been with TC Energy 14 years, during which he has performed several different roles—including pipeline integrity, construction, and technical support—and provided expertise within TC Energy for materials and welding. James holds a BS in materials engineering from the University of Alberta and is a Registered Professional Engineer with Association of Professional Engineers and Geoscientists of Alberta (APEGA).

David Milmine is a technical consultant with TC Energy, Calgary. He has spent more than 40 years in a similar capacity as a consultant to TC Energy and other corporate entities, in the areas of technical material specification preparation, supply facility evaluation, and management of quality assurance services. He holds a BS in mechanical engineering from the University of Alberta and is a Registered Professional Engineer (APEGA). He is a long-standing past member of the CSA Technical Committee on petroleum and natural gas industry pipeline systems and materials and affiliated subcommittees and holds certifications under CAN/CGSB 48-9712 as a radiographic and ultrasonic operator.