P. 5 ~ Continued - Mixing MDEA, TEA shows benefit for gas-sweetening operations

View Article as Single page

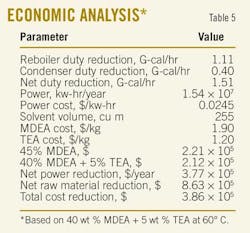

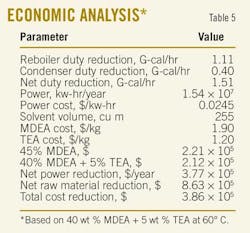

Economics

Solvent conversion or gas plant revamping is usually done in order to increase production or decrease plant operating cost. To confirm this practice, we conducted an economic feasibility analysis for OGD II gas sweetening unit to calculate the gross profit gained through the use of MDEA-TEA mixture (40 wt %. MDEA + 5 wt %. TEA) compared with the use of the pure MDEA solvent. GASCO provided the average raw material price for both MDEA and TEA. The power cost is assumed equal to the one used by GASCO's Habshan operating utilities, and amine solvent needed is equal to 30% of the fixed-roof storage tank volume used in the unit.

We derived a model (Equation 9) for the variation of the H2S concentration with trim-cooler temperature based on the results displayed in Fig. 5[4].

Adding 5 wt % TEA at 61o C. resulted in increasing H2S concentration in sweet gas from 121 to 136 ppm (vol). Simulations predict that a decrease of the temperature to 60o C. will reduce the H2S concentration to its initial value (the one obtained with pure MDEA solution 45 wt % and a trim-cooler temperature of 61o C.).

With this temperature, a reduction in the cooler duty is observed due to reduced reaction exothermicity, which lowered the absorber bottom stream temperature. Furthermore, this resulted into an inlet-cooler stream with a lower temperature and a reduction in the cooler duty of about 4.14%. Table 5 shows the approximate savings ($386,000/year) if an optimized process of adding 5 wt %. TEA and reducing the trim cooler temperature to about 60o C. is utilized.

Blending different types of amine solvents appear to benefit gas sweetening processes. This article has examined the effect of mixing two tertiary amines of MDEA and TEA on the amine sweetening unit's energy cost. Literature shows that TEA has a lower heat of reaction, lower CO2 rate of reaction, as well as lower acid-gas capacity compared to MDEA.

Comparison among different blends showed that MDEA-TEA mixture requires the lowest regeneration energy duty. Moreover, it still maintains the mixture selectivity due to the lower CO2 reaction rate and loading capacity which resulted in lower H2S content in sweet gas.

In comparison to single MDEA, TEA holds a smaller acid-gas loading capacity, which reduces the volume of acid gas it can absorb. Therefore, an investigation predicted the effect of altering the trim-cooler temperature in order to maintain the initial H2S concentration with single MDEA solvent. Results showed that about 3.0% reduction in running cost can be obtained for the OGD II unit.

An economic analysis calculated the money savings by utilizing (40 wt % MDEA + 5 wt % TEA) mixture to treat the sour feed gas. Results showed that up to $386,000/year/unit can be gained at a lean-amine loading of 0.005. Decreasing the latter has proved to lead to a further reduction in the required regeneration energy if the recommended tertiary amine mixture was used.

Acknowledgment

Financial support for this project was provided by the GASCO and Adgas operating companies of the Abu Dhabi National Oil Co.

Displaying 5/6

View Article as Single page