GLOBAL MOBILE OIL & GAS ASSETS – ONSHORE AND OFFSHORE EFFICIENCY

Leading global enterprises that own and operate large mobile assets such as floating production storage and offloading (FPSO) operators, drilling contractors and other vessel owners in the

oil and gas industry can increase profitability by improving efficiency, taking control of project risks and optimizing global operations both onshore and offshore. This requires total real time visibility of their global business, including global finance, project and asset management, complex international on- and off-shore supply chain and offshore asset productivity.

To improve business efficiency onshore, finance departments need better support for creating new companies in their system of record, processing multi-company transactions and sophisticated reporting and analysis tools to operate across countries, companies and business units. In addition, a complex global supply chain represents an opportunity to achieve significant business improvements through better global sourcing and framework agreements offshore inventory management and follow-up. More efficient maintenance due to better job planning, materials and resources will allow companies to move staff onshore.

Emerging technologies such as big data, internet of things (IoT), augmented reality, digital twins present new opportunities to optimize offshore operations, connect with HQ and provide total visibility. The key to realizing the value they offer is the ability to identify where exactly to deploy them and how quickly and smoothly they can integrate with existing business processes.

AN ENTERPRISE SOLUTION FOR BOTH ONSHORE AND OFFSHORE

In a single, proven software solution designed for the industry in consultation with our customers, IFS supports project management, asset management and global finance and business operations. Implementation is straightforward, and the result is reliable onshore and offshore with intuitive

usability that eases training and acceptance.

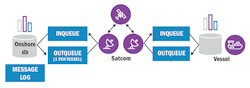

One of the major challenges global mobile asset owners face is real-time communication of transactional information between offshore units and onshore locations. IFS turns this challenge into a competitive advantage for our customers with IFS Instant Replication™, a standard offering that uses satellite technology to mirror transactions and activities in an offshore instance of IFS Applications with an instance run on the shore side. This means that for IFS customers, offshore operation always has system support even when operating in areas with no satellite communication. Yet onshore operations always have current information on the status of each offshore asset from serviceability to inventory on hand to current contributions to cost, revenue and margin.

The data replicated between onshore and offshore is highly configurable, but generally includes:

· Master data on parts, suppliers and asset structures

· Procurement information including requests for quotation, purchase requisitions, order quotations, purchase orders, supplier blanket agreements, authorization and receipts

· Financial transactions triggered by logistics processes, work orders, chart of account changes or accounting rules changes

· Documents, including equipment manuals and schematics, which can also be then attached automatically to relevant part records, work orders, purchase orders or asset structures.

Data replication gives you one system, one version of the truth and one right set of numbers for your entire geographically dispersed organization. And it is standard commercial off- the-shelf technology, which eliminates the cost and risk of systems integration.

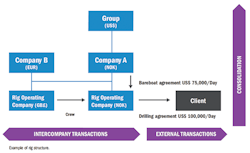

GLOBAL FINANCE AND COMPANY STRUCTURE

A company’s viability has never been so intrinsically linked to multiple external factors. Remaining connected to relevant, fast-moving external data and being able to analyze and action is mandatory in a rapidly shifting global environment. A single enterprise, for instance, often needs a multi-company structure to operate in different countries and meet various regulations. One single enterprise may have an asset-owning entity and multiple geographic operating companies.

IFS offers a comprehensive enterprise resource planning (ERP) suite that supports a global finance organization with tight integration to operational functions like world-class project management, asset management and supply chain management. This broad and deep offering has made us the enterprise solution of choice for oil and gas enterprises worldwide according to market share and analyst opinion.

Mobile offshore asset operations present unique challenges based on where the vessel is operating. They tend to for instance set up multiple operating companies to ease tax and regulatory compliance for:

· International Financial Reporting Standards (IFRS)

· US Generally Accepted Accounting Practices (GAAP)

· Sarbanes-Oxley (SOX)

· Nota Fiscal in Brazil

· China’s Basic Standard for Enterprise Internal Control

Companies also must not only comply with financial measurement requirements, but also non-financial metrics around human rights, ISO accreditation, or corporate social responsibility (CSR) expectations of governments and stakeholders including customers and investors. In natural resources-intensive industries like oil and gas, the burden of CSR compliance is increasing, and can be a determining factor in an organization’s ability to operate or to be selected for work in a given region.

There are a number of under-appreciated business processes that may differ according to region or jurisdiction including:

· Risk management, including system safety engineering, procedures and

· Visibility and control of the environmental impact and cost of operations

· Environmental regulation

· Quality assurance (QA) and health, safety and the environment (HSE) management, including safety policy management, risk assessment, incident management, and key performance indicator (KPI) reporting

· Tax methodology affecting, supply chain and spare parts availability

The final two bullet points above, tax considerations and HSE, bear close attention as they both present significant financial implications for offshore. Spares and repairs inventory on rigs or vessels are often subject to taxation as depreciable inventory or capital property. Decisions about where to house spares and repairs may depend in part on the resulting tax exposure balanced against the desire to have the inventory close to the site of deployment. HSEQ meanwhile marries traditional HSE practices with quality, because in oil and gas, a quality-Based failure of parts and equipment can result in loss of life, environmental spoilage and serious liability risk for the organization. IFS Applications not only streamlines HSE reporting by pulling from operational systems used to maintain and repair assets, but includes integrated quality management and quality assurance functionality.

In the global environment the offshore oil and gas industry operates in, these requirements change based on the location of the mobile asset. An enterprise-wide software system must enable a management team to ensure compliance in the local waters the vessel or rig is operating in at the time without leaving money or productivity on the table in a less rigorous regulatory environment. Multiple regulatory and tax environments, multiple countries and currencies, multiple units of measure–IFS Applications keeps you one step ahead as the location of your offshore assets change.

Even as IFS solutions support unique requirements of local waters, the software also allows you to think and act globally. Business processes are not just multi-company, multi-geography and multi-language but cross-company, cross-geography and cross-language. This lets you run a portfolio of projects in multiple currencies and languages, multiple asset service and supply chain modes in the same application with full visibility and sound governance. In addition, it’s possible to consolidate results and ensure tax compliance globally, while ensuring that you meet all local requirements.

PROJECT MANAGEMENT

Speed and agility are at the heart of successful oil & gas operations. Being able to quickly exploit new sources as they are discovered is essential for profitability—perhaps even survival—in the sector. In order to keep up, operators must be empowered to reposition their extraction, production and storage fleet to access new opportunities and move away from less-profitable or depleted wells. Asset owners will often build new assts, refit existing assets for a new well. From the events associated with asset refit and redeployment to months or years of offshore deployment, oil and gas is a project-intensive business that must be built not around repeatable processes

but unique projects with multiple dependencies, and a focus on real time tracking of risk, cost, cash, revenue, margin progress and delivery time. Therefore, the ability to efficiently manage projects of various sizes, durations and complexity is crucial for those managing mobile oil and gas assets.

However, most enterprise software does a poor job organizing a business around multiple projects. Traditional organizational structures and separate legacy software applications normally make it difficult to understand real-time operational situations, which delays corrections to resourcing and supply. Delays are expensive, and can make it almost impossible to determine whether an opportunity will ultimately be profitable. For this reason, organizations that attempt to manage the through-life maintenance of mobile assets with discrete software solutions for project management and asset management will be unable to hold a complete picture of the asset configuration required for an efficient maintenance program.

Instead, structuring a business around a network of integrated projects—rather than fixed departmental or geographic silos—is fundamental for success. This can be achieved with a truly integrated enterprise system that enables companies to move from being departmentally constrained to truly embracing end-to-end processes. In addition, this gives managers better progress visibility, enables efficient risk management, and allows for instant adjustments.

To track complex projects, it is necessary to establish a structured, controlled way of managing them via the ERP system. The system should let you:

· Monitor all cost, progress, and changes

· Plan for verifications, audits, or non-conformance reports of the asset and personnel working on the asset

· Visualize status of all projects using built-in reporting tools

· Be flexible; operating unit set-up as a company or project contract to improve cost forecasting and to gain better visibility of critical cost elements.

IFS Applications offers a complete project lifecycle management solution with a strong focus on financials, materials, subcontracting, human resources and asset management integrated tightly the standard functionality used to run projects.

ASSET MANAGEMENT AND GLOBAL SUPPLY CHAIN

Offshore mobile facilities must be kept operational to maximize throughput and revenue generation while maintaining best in class standards for safety and environmental management.

Delivery of equipment and spare parts is a critical activity for offshore companies, especially in complex off-shore environments. Even if operation requires a standard part or consumable, that part or consumable may be in a supply chain far removed from the unit, and simply transporting it to the required location may consume valuable days or weeks.

In many other cases, parts or subassemblies required for replacement or upgrade may be long lead time items that must be custom fabricated or made to order by a vendor. It is essential to use an ERP system with rigorous spares and repairs inventory functionality. Software must also streamline material transfer

to reduce shipping costs and planned or unplanned downtime.

It should also include management of palletized inventor, intermodal containers and other load carriers for on- or offshore deliveries. To support these offshore processes, functionality

for efficient transport order management is essential.

An often-unappreciated element of supply chain management offshore is equipment. Regardless of whether equipment required is rented or borrowed from an offshore company’s own yard, it must be accounted for in a project plan and its accrued against the revenue-generating project in question.

IFS offers the best-in-class enterprise asset management (EAM) functionality operators need to manage the complete asset lifecycle, with strong functionality in maintenance, advanced inventory management, document management, procurement & logistics and financials. Ideally, head office onshore should have complete and swift insight into operational effectiveness and costs as they are incurred.

This will enable oil and gas businesses to secure visibility, and simplifies the follow-up of parameters such as:

· Shorter idle periods during refits as part and equipment availability are coordinated centrally in a project plan

· Reduced unplanned downtime

· Increased completion percentages of planned maintenance work as delays due to part unavailability are avoided

· Lower tax exposure as spares and repairs inventory can be either reduced through better visibility of planned demand or allocated to different rigs or vessels in order to minimize assessments

· Higher return on investment on capital assets as unproductive time is reduced and proactive management reduces cost of spares and repairs inventory

· Increased safety and reduced risk profile as improved maintenance and operation practices reduce lost time injury along with the likelihood of environmental health impacts.

The EAM functionality in IFS Applications is used to manage facilities and equipment in a company on both a micro and macro level. This asset management functionality creates a single universe encompassing:

· The general ledger

· Contract management

· Purchasing of maintenance consumables and capital equipment

· Work orders used by front line maintenance technicians

· As-designed, as-built and as-maintained documentation for a complete view of the current versus original state of the asset.

Throughout the application suite, different types of asset financial transactions are created at the source based on the common defined accounting model, with updates reflected in the general ledger. An asset under construction categorized as a project can be transferred to an asset when finished, completely or partially. This data from the construction and design phases flows seamlessly into operational and maintenance systems, giving everyone touching the asset a single version of the truth that reduces cost and increases operational effectiveness and safety. The system also supports a comprehensive range of depreciation methods that can be used simultaneously—for instance for tax and local legal purposes. So from operations to finance, IFS Applications enables effective real-time decision in mobile oil and gas assets.

A DIGITAL PLATFORM FOR INNOVATION

The momentum and excitement surrounding emerging technologies such as big data, artificial intelligence (AI), digital twins, Internet of Things (IoT), robotics and augmented reality

is real, and these technologies can drive measurable value for organizations operating mobile offshore oil and gas assets.

But the excitement that accompanies novel technologies can distract us from asking the vital business questions that help us use technology to solve real problems. First, why should global businesses in oil and gas—already operating complex business processes that generate a wealth of information—be interested in these innovations? Second, which of these different technologies add value to the business? And third, where in the global landscape should they be implemented to achieve the greatest value. Like any innovation, the technology associated with

digital transformation should only be implemented when and where it adds real value. This could for example include preventing unplanned maintenance using IoT or robotics, enhancing spare parts forecasting capabilities, robotics in finance, analyze of big date, adding remote communication to upskill technical staff, etc.

With an integrated enterprise solution, it’s easy to identify the areas where the fine tuning and optimization benefits these technologies offer can deliver the greatest value. Performance management tools like IFS Lobby™ provide end users with tailored dashboards; IFS Enterprise Operational Intelligence™ provides the C-suiter with a single global picture of performance for each step in the value chain and enables greater stringency in aligning performance with strategy.

In asset management the value is clearer: sensor technologies, IoT and AI minimize expensive and risky human maintenance intervention while facilitating predictive and condition-based maintenance.

In addition, the agile modular IFS product suite enables businesses to easily integrate emerging technology trends into their established processes and enterprise IT landscape to realize the value of new technology.

CONCLUSION

IFS is one of the world’s leading providers of business software to companies within the oil and gas industry. We offer a solution that can support the enterprise breadth of a business operating onshore and offshore, across multiple regions and territories while also delivering the depth of functionality required to manage the key areas of global finance, project-management, supply chain and asset-management.

The enterprise visibility this inherent integration delivers enables leaders to easily identify the areas or processes of their businesses where innovative technology can deliver the greatest value, and the modular agile architecture of the product suite enables these tools to be adopted quickly and business processes easily adapted to incorporate them.