Front End Loading provides foundation for smarter project execution

Integrated approach paves the way for business and technical success

A recent analysis of project management literature generated alarming results; approximately 70% of projects in the last five years were not completed on time or within budget.

When placed in the oil and gas industry’s current landscape of escalating demand, increasingly complex assets and tightening profit margins, the challenge before today’s operators is clear: How can you optimize resources, account for numerous environmental, political and social constraints and still meet a project’s technical and business goals?

Meeting this challenge requires strategic know-how from the very beginning of a project. Front End Loading (FEL) is a methodology that takes a deliberate approach to capital project planning. The FEL methodology is currently being applied by many operators to optimize asset production operations and well construction design and maintenance.

Where traditional project plans seek to help an operator reach production targets and budgets, FEL methodology aligns an operator’s technical and business goals to create a more comprehensive development plan. By integrating professionals from multiple surface and subsurface disciplines and equipping them with the industry’s latest technology, the FEL approach increases project definition and lowers risk to positively impact total investment costs and return on investment.

While the FEL approach is an established project planning method in many industries, it is widely underutilized by upstream oil and gas operators. Organizations like Halliburton’s Landmark Consulting and Services group are now pairing the methodology with established implementation processes to create field development plans that serve as springboards to smarter project execution, less nonproductive time, and greater return on capital.

At the heart of Landmark’s FEL approach are three critical elements: a well-defined uncertainty and optimization framework, the industry’s best technologies for integrated asset modeling, and the creation of multidisciplinary teams that generate unique project insights.

Increased project definition

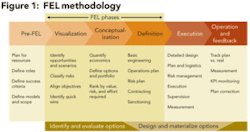

A FEL project plan is created in three distinct phases to ensure an exhaustive alternative capital analysis. During the first two phases – visualization and conception – all possible business opportunities are examined. As the benefits and risks of each opportunity are explored, the scope of the project at hand is refined and the number of possible scenarios is decreased. During definition, the third FEL phase, basic engineering is completed for the best field development scenario.

Between each FEL phase, Landmark consultants implement several key peer reviews. Conducted by a multidisciplinary team, these peer reviews provide a chance for executives and employees who are not intimately involved with the project to evaluate the plan as it is created and to offer recommendations.

Additionally, peer reviews provide an opportunity for the project team to adjust the development plan in a project’s early stages – before costly equipment has been purchased or irreversible execution steps have been taken. Because the FEL approach requires exhaustive identification, screening, and optimization of all possible development scenarios, it proactively avoids costly rework at later project stages.

Technology for complex uncertainties

The technical complexities found in today’s oil and gas assets are tied to numerous uncertainties about reservoir characteristics, well performance, and equipment failure rates. At the same time, market volatility has contributed to reduced confidence in profit margins and increased the cost of moving equipment and employees to the jobsite. Add to this social, environmental, and political questions, and the oil field may have never seemed so vague.

Conventional project planning methods account for some uncertainties but tend to ignore those that don’t fit into existing models or those that pose untraditional challenges. Traditional approaches also direct professionals to work only within their discipline, so uncertainties that are accounted for in subsurface operations are often not projected to corresponding surface operations.

The result is an inaccurate, unreliable field development plan. The FEL methodology overcomes the faults of conventional project planning by leveraging the industry’s latest visualization and analysis technology and a multidisciplinary project team to examine all uncertainties from a whole-asset perspective.

Technology is a critical component of a FEL development plan. Software offerings like numerical and stochastic simulators and risk analysis software allow Landmark consultants to evaluate hundreds of development scenarios and account for complex uncertainties. In turn, teams working under the FEL approach can gather critical insight into the project and confidently identify the best development plan for the asset at hand.

Collaborative project planning

Traditionally, project planning is done sequentially. Reservoir engineers model reservoir response to the bottomhole, production engineers model the wellbore to the wellhead, and process engineers model surface facilities from the wellhead to the tank. Under this divided planning approach, each individual draws conclusions about the inputs and outputs of his or her specific section of the process without regard to holistic project optimization.

The FEL project planning approach calls for a project team that integrates professionals from several upstream disciplines. Integrating previously divided field development functions brings new perspectives and levels of experience to project planning discussions and prevents confusion by laying out goals and expectations before a project is underway.

The result is a comprehensive plan that accurately accounts for uncertainties through all stages of development to maximize production and returns. The FEL process ensures that key stakeholders have the opportunity to contribute to the plan from insight to project execution.

Case study: FEL in rapid field development

An operator recently experienced the benefits of the FEL project planning approach firsthand in the face of an urgent deadline. In only two months, the company needed to efficiently and intelligently develop a field development plan for two offshore gas fields that not only met technical goals, but would minimize environmental impact, navigate local social development issues and, ultimately, accomplish the greater business goals of the organization.

Landmark immediately turned to FEL because it offered an organized thought process for efficiently evaluating many development scenarios.

The project team started with a single, most likely, base-case scenario from previous field analyses. However, the scenario did not provide any alternatives to capital investment or consider the effects of uncertainties. To ensure that the operator could obtain the necessary drilling and environmental permits, the company needed to demonstrate that it had a well-informed plan that worked within the field’s constraints.

Under a traditional planning process, a small number of realizations are examined to determine the best, worst and most likely development scenarios for the project at hand. Utilizing the FEL approach, the project team was able to visualize more than 100,000 scenarios to confidently choose the best field development plan – one that maximized production and profit.

Using rapid wellbore planning and a reservoir quality index, more than 200 possible well target locations were identified with multiple architectures, completion zones, and surface locations. When these targets were exhaustively analyzed based on the dynamic response of the field, including an integrated evaluation of reservoirs, surface facilities, and economics, 16 well locations were optimally chosen for the two fields. After just eight weeks of analysis and evaluation, the FEL approach yielded a fully integrated conceptual development plan that met all project objectives.

As a result of such effort, the project team provided a plan that could drain the field’s reservoirs more effectively with even fewer wells than the base case previously thought – an insight that saved the operator more than $150 million. The plan provided under the FEL methodology also showed that early production could be higher than originally thought – production could be increased by 30% for the first five to eight years and water production could be delayed for several years.

Better insight for smarter execution

FEL aligns technical goals and businesses objectives to pave the way for intelligent field development planning. The insight developed by this comprehensive project-planning process generates confidence that an operator’s capital resources are being deployed efficiently and effectively. The result is project success in terms that everyone can agree on: lower costs, greater efficiencies, and maximized profitability. OGFJ

About the Authors

Luigi Saputelli, PhD, has 18 years of experience in the oil industry working with major integrated operators and service companies. He is widely recognized in the industry with regard to reservoir and production applications. He currently serves as Halliburton’s Landmark Global Practice Manager for Field Development.

Rob Hull, MBA serves as Landmark’s Asia Pacific Practice Manager in Kuala Lumpur, Malaysia. He has 24 years in the industry working directly with various operators, technology providers, and consulting groups. He established a specialty in work process improvement, technology deployment and project management. His background as a geophysicist and reservoir engineer has provided him with a keen understanding of the entire E&P workflow from field development to facilities optimization. He received a bachelor’s degree and an MBA from Canterbury University in the United Kingdom.

Alvaro Alfonzo, PhD serves as Landmark’s Mexico Managing Consultant in Villahermosa, Mexico. He has 25 years of experience in the oil and gas business. Dr. Alfonzo has practical experience in Venezuela, Mexico, Algeria, and Trinidad. He obtained a bachelor’s degree from The University of Tulsa, a master’s degree from MIT, and a doctoral degree from URBE University, Zulia Venezuela.