Who moved my rig?

Reducing drilling costs through more efficient rig mobilization

Alex Buehler and John Charwinsky,The Marshall-Teichert Group, Houston

Drilling activity across the industry has recently surged as the price of oil has recovered. The demand for available rigs has increased and hourly cost of rigs is rising once again. According to an industry source, utilization of onshore drilling rigs has increased to above 50% since bottoming in 2009. The effective rig utilization is actually higher than 65%, because the new demand for horizontal drilling in shale formations has narrowed true demand to very specialized multi-purpose rigs, which can be deployed among a growing range of complex drilling environments and variety of new regulatory compliance requirements.

In the days prior to the oil market crash, onshore rigs were available for nothing less than thousands of dollars per hour, and many companies in the industry were signing long-term contracts with rig contractors to lock-in rates. Some of these contracts contained hefty exit clauses, and every minute of rig utilization was critical to the cost-effectiveness of each new well drilled. Downtime became a four-letter word.

We're headed back to this territory and the lessons learned from the last boom ought to be given appropriate attention to avoid some of the hidden, but costly mistakes made by most every company in the industry. More technology and more engineering time are now being focused on the drilling rig. But one area stands out as an area in need of continued improvement – Rig Mobilization (Rig-down, Relocation & Rig-up). This process, benefiting more from improved communication and leadership techniques than technology, can be a huge cost driver.

Consider the following scenario: A major independent oil company, drilling in the Washakie Basin of southwest Wyoming, contracted its rig mobilization to an outside service provider. As with its relationship with other oilfield service contractors, the emphasis in the working relationship was on getting to the next drilling location as quickly as possible, with little attention to cost or process. A room full of engineers and managers typically gathered daily to review the minute details of drilling progress, but this group would then take a hiatus between locations while full control was handed to the moving company.

While the target for relocating the rigs was two to four days, typical moves took twice as long and lasted up to 10 days in inclement winter weather conditions. During an observation in mid-March, while the move crew was loading equipment modules onto its flatbed trucks, they attempted moving a compressor module (known as the "grasshopper" due to its asymmetrical center of gravity). Not having spreader bars available onsite, required for the crane to lift the module onto the flatbed, the crew attempted to pull the module onto the rear of the bed with a power winch. Half-way up the back of the truck the module fell to one side, completely crushing the wire harness, requiring seven additional days of repairs to rebuild the module.

Neither the moving nor rig crews followed their own procedural requirements for loading equipment. An investigation revealed they did not have a good plan in place, including having the right equipment available, nor was everyone on the move crew aware of the plan or procedures to do so.

A lean management approach

Lean management experts who have studied the drilling process have concluded that approximately 25% of average rig activity time is classified as mobilization (Fig. 1). According to a 2009 study entitled, “Surviving the Downturn, Building for the Future” by Alvarez & Marsal, "standardized rig mobilization processes are typically optimized through a series of kaizen events that analyze existing work processes and focus on driving out non-productive time. Rig move activity cycle times are measured and tracked against targets using visual controls to minimize activity variation. In turn, effective communication and planning significantly eliminate non-productive time, such as waiting on third party moving crews, or equipment, at the new location. Rig move cycle times are typically reduced by 35% to 50%, resulting in savings of up to $120,000 per move depending on daily rig rates and move distance."

Figure 1: Summary of typical drilling rig time distribution (adoptedfrom 2009 Alvarez & Marsal study)

Published studies such as these underscore the tremendous costs associated with inefficient drilling process management, as well as the urgency for tighter controls on planning and execution. Success in this arena typically requires an organizational change management initiative to enable sustainable improvement of the process. Here are some tips and tricks for recognizing if your drilling program needs improvement in rig mobilization controls, and some techniques for implementing simple improvements to get near-term results.

Outsourced or directly controlled?

Who is responsible for moving your rigs from one location to the next? Both in-house and outsourced resources are used to move drilling rigs across the industry. Each scenario has its own selling points. Outsourced hauling companies typically have more specialized equipment and capability than internal resources for relocating a drilling rig and getting it done quickly.

The challenge is that an outsourced hauler adds another level of communication complexity to the process, and needs to be managed more closely than internal resources to ensure the contractor is adjusting its plans to manage external influences, such as dispatch, availability of equipment, coordination with the drilling rig foreman; and overcoming unexpected obstacles in the move plan, such as weather and route exceptions that could jeopardize the release to spud schedule. Maintaining these hauling resources in-house, however, carries additional cost, maintenance and availability challenges.

A rig move coordinator (Truck Pusher) has the responsibility for managing the hauling resources and closing the gap in communications between the hauling company, the drilling foreman and the drilling engineers. The move coordinator may be employed by the drilling company, or work for a contractor that has expertise in mobilization practices. An effective rig move coordinator participates in the planning of the move, scouting the next drilling location and identifying any possible hazards or delays, thereby keeping every aspect of the move safe, efficient and productive. Whether in-house or outsourced, it is important to involve the rig move coordinator in the same level of management attention as the drilling superintendent or company man – they all have specific roles that contribute to the success of the rig move process.

When working with an outsourced rig mobilization contractor, it's important to involve them in schedule updates, performance reviews, root cause analysis discussions and problem-solving to address opportunities. Such items should be included in contract terms, so that an incentive exists for contractors to participate in and benefit from successful cost reduction initiatives.

Standard operating procedures

Whether you're employing H&P Flex rigs, Nabors M & F series, or Cactus Rocket Rigs, there should be a standard operating procedure (SOP) in place covering the steps required for preparation and execution of a rig move. The SOP should extend to specialized equipment that is used to load, transport and unload rig components. A physical check should be made to ensure that these SOP's exist and that they are accessible to the hauling crew, the rig crew and the rig move coordinator. These procedures should outline the proper steps to complete all tasks safely. SOP's should always be accompanied by Joint Safety Analyses (JSA's) to effectively emphasize the existence of safety hazards and communicate them to all involved personnel. Replication of success, especially regarding safety, is critical in gaining efficiencies in the move process.

The results of not following procedures include equipment damage, schedule delays, and even injuries, because the crew applies "best guess" to a loading or unloading step rather than following procedures. Sometimes special tools, such as cranes and spreader bars are needed for loading rig equipment. If they are required in the standard operating procedures, they should be included in standard rig-move inventory. All departures from procedure only add to the cost of moving your rigs.

Route planning and site reconnaissance

This isn't just verifying roads on a map and laying eyes on the next drilling site. A detailed checklist needs to be developed to include road permits, mobility obstacles and site conditions in both good and inclement weather. This checklist should be completed and reviewed with management and the move crew before the first crane, tandem, or hauling truck shows up on location. Plans and expectations must be supplemented with alternatives for poor weather conditions and visibility.

Staging of resources is typically a problem because of narrow, unmarked lease roads and limited entrance and exit lanes to the drilling rig location. These limitations leave open the opportunities for communication to break down, or vehicle drivers to become lost, or off schedule, especially if the staging areas are out of sight from the actual loading or unloading locations. The best approach is to drive the route to the next drilling location, look for potential staging area locations, note the landmarks to be communicated and develop alternative plans to overcome obstacles, or hazards such as mud, ice or snow that could cause potential delays.

A rig move planning and execution process

Every good football coach works from a playbook that tells him which plays to call during the game, as well as alternative plays that may hinge on field conditions, the spot of the ball and the tactics used by the opposing team. A rig move schedule harnesses the similar, multiple levels of complexity to plan each step of the rig move that can be adjusted with "what-if" scenarios, such as whether a step can occur after dark, in inclement weather, or in poor visibility. An effective rig move schedule encompasses all the variables that can have an impact on the safety, quality and timeliness of the outcome. It should be reviewed and communicated with all parties involved in the rig move process and be used as a management tool.

The levels of complexity and coordination of multiple resources working on a move can appear overwhelming when you look at the move as a whole – a rig move schedule/planning tool (Fig. 2) allows for the move to be broken down into more easily managed pieces. To build an effective rig move schedule, gather the following information into a decision matrix:

• Identify the individual steps required to rig-down, load, transport, unload, and rig-up the equipment

• Determine the average time to complete each step, both in good and inclement weather conditions

• Indicate whether daylight restrictions prevent any step from being accomplished in the dark

• Highlight special inventory items or permits, which must be on-hand prior to starting the rig move

Communicate this plan to all parties involved and check for understanding and agreement before proceeding with the next steps in the process. Ensure that all changes to the plan, as well as the responsibilities for executing the changes, get communicated as well. Planning is the most critical element of success in minimizing move costs. Remember – the cost of the rig doesn't go away just because it's moving to the next site – so it's important to get back to drilling in the safest and fastest timeframe possible. The goal is to reduce costs by minimizing delays through improved planning and effective and timely management of the move.

Measuring success

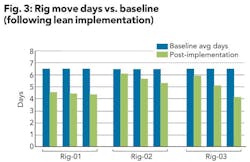

Establishing and tracking key performance indicators will help drive efficiencies in your rig mobilization program. Start by establishing a baseline of the historical days between rig release and spud. Pay particular attention to differences in seasonality, as this will help you develop realistic goals based on conditions. Targets need to be based upon what is controllable in terms of process and behavior.

Exploring variances can result in discovery of breakdowns in communication and failures to follow established procedures. One particular exploration company found ways to reduce their rig-release to spud days by nearly 40% in a winter environment, simply through tracking and applying root-cause analysis to variances between actual and target rig move days. This focused their optimization efforts on putting more controls onto a few variables instead of on the entire process.

To track results, ensure that the rolling average of each successive rig move step's duration is published against the established historical baseline and target (Fig 3). Following each rig move, conduct a quick review of steps that went well, and those that did not. Involve the transportation contractor/crews and note the weather conditions as well as details about when delays occurred for later analysis. These discussion notes will add tremendous value in identifying trends and patterns. Schedule a root-cause analysis session approximately every quarter to review these trends and adjust your management focus on addressing the pinpointed issues.

When you begin to see reductions in the average rig move-days, document the best practices that contribute to the reduced cycle times, celebrate success with the entire team, acknowledging their value. Successful rig mobilization is not only measured in days, but also in potential million dollar, bottom line cost savings annually.

About the authors

More Oil & Gas Financial Journal Current Issue Articles

More Oil & Gas Financial Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com