Minimizing the impact of changes on oil and gas construction contracts

Barry Bramble,Trett Consulting, Houston

Executives and project managers for operators, service companies, contractors, and vendors on oil and gas projects are very concerned these days with the profitability and risks on their contracts. Whether it is for subsea activities, offshore platforms, floating production vessels, or other O&G facilities, risk concerns are getting more attention as pricing becomes more competitive.

The increased concerns may be due to fewer projects being put out for tender in certain geographic areas such as the Gulf of Mexico. Even in parts of the world where O&G development is expanding (like offshore Brazil), the players are becoming more risk–aware. For example, many US–based contractors are uncertain about the unfamiliar contracts used in Brazil, costs of local labor forces and risks involved in using mandated local vendors.

Risks are greater for projects in West Africa, where concerns include local political considerations and the uncertain aspects of labor, material handling, and other field logistics. Many of these risks on O&G projects are dealt with by provisions in the contracts between the parties.

Most contracts for engineering, fabrication, and/or installation of O&G facilities are complex commercial agreements, often as complex as the technologically advanced systems, components and structures involved. Despite the sophistication of the agreements, most have standard terms for changes and variations. According the changes provisions in many agreements, the contract price and time can be adjusted upward (or downward) due to changes in field conditions, requested technological improvements, evolving environmental regulations and a host of other conditions both favourable and unfavourable. Unfortunately, in many instances the contracts are not properly adjusted when the circumstances and conditions change.

It is the application and administration of these change provisions that is potentially problematic. The contractor may fail to recognize when a "change event" occurs, and the operator may deny that an adjustment to the contract is warranted. Contractors and vendors may not properly notify the operator or employer that changes have occurred or fail to comply with the appropriate contract clauses. Frequently they fail to keep the type of records necessary to demonstrate that changes did indeed occur or their effect on time and costs.

A common problem is the failure to designate specific cost codes to capture labor, material and equipment costs associated with the changes. While many contractors and vendors have cost systems to capture the obvious direct costs of changes, most do not capture indirect costs and these may be substantial. For example, engineering hours are rarely tied back to field change events, so enormous engineering hour overruns may be incurred.

Also, the extended costs of special equipment and overhead costs may not be tracked if the change prolongs field performance. While a one–month delay to project completion can cost the operator huge losses in production revenues, a contractor may incur significant delay–related costs that are not recovered by change orders.

Given the current economic situation and the need to maintain good relations with operators, many contractors will try to keep within the bounds of the cost, time, and quality terms of the contract. In fact, many contractors are wary in invoking their contractual rights to cost and time changes.

Due to unexpected events, however, schedule slippage, cost increases, and quality problems do surface. Failure of the parties' project managers and field staff to address change–related issues during the course of contract performance may lead to significant cost overruns and delays to completion. Such problems may jeopardize timely start–up and production for the operator and cause delay in resolving the contractor's final account.

When these problems finally come to the attention of senior managers and project executives of the operators and contractors, it may be too late to resolve the issues by a mutually satisfactory contract adjustment. Unfortunately, such disputes between the parties strain client relationships, and the contractor may even feel compelled to submit a formal contract claim.

When it gets to that stage, all too often the end result is that one of the contracting parties may file for arbitration. This may even be the case for operators and contractors who maintain long–term relationships or are otherwise averse to dealing with problems in such a manner.

Changes are best addressed when the matters first arise. The issues at that point in time are: (1) expeditiously dealing with the immediate logistics of the change; (2) addressing ways to mitigate the underlying problems; (3) documenting that there is a change event that warrants a change order; and (4) tracking the true costs involved. In the overall scheme of things, these issues are more easily resolved by taking pro–active management action and developing creative engineering solutions, and then fairly applying the contract terms.

If the problems are not resolved, serious disputes may arise over whether the contractor or vendor is even entitled to a contract adjustment, but by that time the cost and schedule impacts may be felt by both the operator and contractor. Even at this point, the disputes can be resolved by give and take, even in tough negotiations, by senior managers who are realistic in assessing their own exposure to the costs and risks involved.

However, if disputes are allowed to fester and project executives fail to come to terms in an adjustment to the contract price and time, the matter may get out of control. The parties may resort to arbitration or courts where the outcome is left to third party decision–makers who may not make business–like decisions. In such situations, business interests may or may not be served.

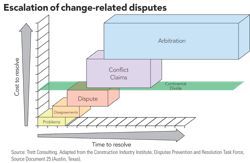

As a result of dealing with the resolution of disputes on engineering, fabrication and construction contracts for over 30 years, the author has observed first–hand that when changes and problems occur on O&G projects, proactive management can solve problems, minimize the cost and schedule impacts, and maintain client relationships. Otherwise change–related disputes result in a continued escalation of tensions that may ultimately lead to arbitration.

As illustrated in the Figure, as disputes escalate, more time, costs, and management time are required to resolve change–related disputes. However, a proactive management mindset and willingness to make tough but realistic decisions at each step along the way can make a difference in resolving matters by contract adjustments and avoiding arbitration.

About the author

More Oil & Gas Financial Journal Current Issue Articles

More Oil & Gas Financial Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com