Innovation from smaller service firms

Mid-sized and smaller oilfield service firms often lead the charge with new technologies

Michael S. Strathman and Anthony R. Strathman, Houston

"If you want something new, you have to stop doing something old." - Peter F. Drucker.

The oil and gas industry has long been known for slow adoption of new ideas. However, there are always innovators and creative entrepreneurs trying new things. These innovative people are found in most companies, but often pursue their ideas in smaller firms where they have more freedom to experiment.

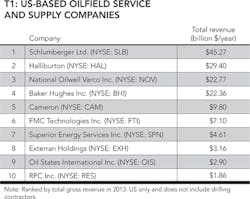

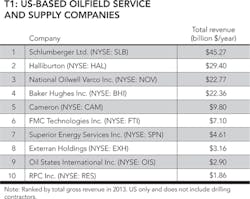

The oilfield service industry is comprised of many companies ranging from very large to very small. Table 1 lists the top US based oilfield service firms. A few large firms dominate.

"Small to mid-cap service companies" are not on this list, but, there are literally thousands serving the industry. Hoover's lists more than 150,000 public and private service firms globally. If "smaller" is more conducive to innovation and creativity, the number of possible technology contributors is enormous.

The new technologies discussed here originate from this segment of the industry. Fundamentally, these firms recognized a problem, applied creative thinking to solve it, and demonstrated the willingness to invest time and money to prove their ideas work. This report examines how these technologies help the industry efficiently supply the world's energy demand.

Helping oil move from the reservoir into the well bore is the ultimate recovery challenge for the industry. Flotek has developed a chemical technology to extract more oil and gas from reservoirs.

Flotek Industries Inc. (NYSE: FTK)

Flotek is a provider of chemicals for the upstream business. Flotek's CnF® frack fluids are unique in their patented environmentally-friendly formulation based on orange oil. Flotek's CnF® formulation consists of nanoscale droplets containing d-limonene derived from orange oil. Due to their size and composition, the droplets alter the interfacial tension between oil and water in the reservoir significantly increasing production. This is a technology advancement in the classic oil and gas sense; a product which directly contributes to production.

As with every new technology, the challenge is "proving" value and encouraging adoption. Flotek developed another technology which verifies these production increases. Rooted in "big data" and data driven analysis, this software solution, FracMax™, aggregates public data on chemicals used in wells and correlates them with reported production figures. It shows quantitatively that CnF® wells consistently produce more than analogous wells that did not employ the CnF® technology.

FracMax™ is more than a case study; it is statistically significant evidence from thousands of wells that using the CnF® formulation correlates with higher production. It is a unique approach addressing the challenge of proving to potential buyers a "new technology" will provide results.

Flotek recognizes the importance of continuing technological advancement and recently announced construction of a Research & Innovation Leadership Center.

Flotek CEO John Chisholm proudly states, "No other oilfield chemistry company, and very few oilfield service companies, has made the financial and human resource commitment to research like Flotek."

Separating hydrocarbons from the rock is a key challenge to increase recovery factors from the 30% to 40% range to 60% to 70%. The future for chemistry in the reservoir is bright, and biology offers another approach.

Photo courtesy of Christie Digital Systems

Glori Energy Inc. (NASDAQ: GLRI)

Glori Energy is an early stage service company with an innovative approach to improve production in fields under water flooding. By definition, these reservoirs need external stimulus to move hydrocarbons to producing well bores. Developed jointly by Glori Energy and Statoil, the Activated Environment for Recovery of Oil (AERO™) platform is a patented biological process for freeing additional oil from conventional water-injection fields.

AERO™ has demonstrated the ability to nearly double daily output of previously uneconomical wells at minimal additional cost. The system works by stimulating in situ growth of microorganisms through the careful injection of a low-concentration nutrient mix. As the bacterial populations grow, they alter the interfacial tension between the fluids in the reservoir, freeing oil from previously inaccessible pores in the rock. It is then carried along with the injected water to be produced.

Nutrient selection and dosage are the critical services provided by Glori Energy. An assay of the microbiology profile of the reservoir is made through examination of produced oil, and is used to design a nutrient mix and dosage to encourage the right amount of growth. Glori's main technological asset is intellectual property and knowledge. The raw materials are common, and additional equipment requirements are both minimal and compatible with most water flood systems. AERO™ requires more biology expertise than the geology or petroleum engineering expertise typically required for most oil and gas technologies.

As always, validating results is critical for adoption, and this innovative company tried an interesting approach. Glori Energy is confident in their technology and invested in operating wells to prove its effectiveness. In the process, they take advantage of low price acquisition candidate properties to prove the production/recovery results, and have significantly improved performance of the technology. Glori Energy has proved results of AERO™ by example.

Flotek's chemical and Glori Energy's biological approach both serve to increase mobility of oil in the reservoir; another approach is more physical. Fracturing reservoirs mechanically increases the surface area of the drainage volume allowing more oil and gas to flow. Holding these fractures open is the role of proppants, often sand. Fairmount Santrol takes traditional sand and gives it a technology facelift, enabling more oil to be produced.

Fairmount Santrol (NYSE: FMSA)

Fairmount Santrol is one of the largest suppliers of proppants, which maximize fracture surface area in wells. Fairmount Santrol recently introduced a new category, proppant transport technology and a new product, Propel SSP™. This transport technology increases hydrocarbon production by improving the distribution of proppants in the fracture network.

Propel SSP™ technology is a hydrophilic gel coating applied to each sand grain. It is delivered dry to the wellsite. Once hydrated in the frack fluid, the coating swells, reducing the proppant's effective specific gravity for massively improved suspension. This enables the coated proppant to travel significantly farther into the fractures. Once in place, a standard breaker will remove the coating, leaving little to no residue. This better transport expands the drainage radius and increases the stimulated reservoir volume.

Fairmount Santrol, which markets technology to operators through OFS companies, is validating Propel SSP™ technology in field trials throughout the US. Operators compare results between similar wells with and without Propel SSP™. For example, in a mid-continent well completed with Propel SSP™ technology, the BOE increased more than 45% compared with the best of seven offset wells completed with a slickwater fluid system. This percentage change in cumulative production continues to increase after 18 months.

In addition to improving recovery from the reservoir, hardware technology contributions improve safety, the environment, or simply reduce cost. Artificial lift is a technology which continues to grow in importance. AccessESP is giving artificial lift equipment a technological update.

AccessESP (Privately held)

Artificial lift is growing in importance as more fields pass peak production years. Electrical submersible pumps are one option, but usually require a drilling rig for maintenance to handle removal of both the production tubing and pump. The limited availability and high cost of rigs in certain locations, combined with service companies looking for lower cost solutions, has created a need for a way to install and retrieve ESP's without a rig. AccessESP has a unique and innovative solution for rig-less ESP deployment.

AccessESP's business is deploying electrical submersible pumps. Its system consists of a landing section installed as part of the original tubing string which allows the ESP to be deployed using slickline. In order to achieve this, the ESP must fit within the tubing inside diameter and be light enough for slickline. The pump's motor must be compact, lightweight and powerful. AccessESP is currently on its fourth generation permanent magnet motor which is more than 80% shorter and lighter than its conventional equivalent. The permanent magnet motor, combined with standard ESP equipment and Access ESP's wet connect system to provide power, allows for rapid deployment and retrieval of the pump assembly using only a crane and slickline.

President and CEO for AccessESP, David Malone, observed, "When I returned to the ESP industry, there were evolutionary improvements in pump design and materials, but ESP technology hasn't fundamentally changed in 80 years." ESPs are a mature technology, particularly when compared to the massive technological and procedural changes in drilling, seismic, LWD, MWD and subsea. AccessESP's deployment system is a fresh approach to a long-proven technology.

Similarly, another company has made significant improvements in a mature technology, cementing.

Blackhawk Specialty Tools LLC (Privately held)

In 2008, Blackhawk was founded to provide highly engineered cementing solutions to improve the quality of wellbore construction. Key to Blackhawk's technology is a patented automated rotating cement head which can be controlled remotely. Benefits include better cementing results, improved rig safety, increased productivity, and reduced rig time for operators. The technology's success can be seen in both project success and industry adoption. Blackhawk has quickly achieved strong market share in the Gulf of Mexico for its engineered cementing solutions.

Blackhawk continues improving its technology through R&D investments including an industry-leading application engineering team which works closely with operators and other service providers. Their analytical and strategic expertise is essential to identify problems in need of resolution and to feed ideas into Blackhawk's R&D process for future innovation. Technology and innovation must address new problems associated with deeper wells (more weight), higher temperatures, pressures, and other logistical challenges. Blackhawk is geared to meet industry needs and changing environments.

The technologies discussed so far are new additions to the oil and gas tool kit. The next technology deals with the operational efficiency of workover rigs, an oilfield mainstay. Key Energy has been a pioneer in technology to improve rig efficiency.

Key Energy Services (NYSE: KEG)

Key Energy Services is a provider of workover rigs. Safety and efficiency are critical to its success. In order to help ensure these, Key has patented a monitoring, control, and data collection system called KeyView®. The KeyView system acquires data from a suite of sensors on the rig that detect a wide variety of parameters, from job times to engine RPM, and tong torque. This collection of data from the workover jobs can then be analyzed to identify opportunities for improvement, validate workover activities, and create a better overall process. Key has employed KeyView for more than a decade, and it is installed on more than 80% of the company's rigs.

Key Energy Services continues to enhance this patented sensor and information technology platform to drive efficiency and safety in the workover rig market.

In addition to workover rigs, sensors are also used extensively downhole. WellDog is an innovative provider of such equipment.

WellDog (Privately held)

WellDog began as a provider of downhole gas testing services for coalbed methane operators using a downhole Raman spectrometer developed in-house. WellDog has introduced a new application of its downhole Raman spectrometer to identify gas and liquids-rich pockets in unconventional shale reservoirs. Due to the different environment, it was modified to run on a standard wireline by miniaturizing the spectroscopy equipment as well as ruggedizing the apparatus and calibrating the spectrometer for the downhole environment. The device provides rapid, in situ, analysis of reservoir fluid (oil, gas, water, CO2, H2S, etc.) composition. By shifting the sampling from the lab into the wellbore, both quality and quantity of composition data are greatly improved.

Driven by varying customer needs, Well Dog continues to expand technology into additional areas including downhole production optimization and reservoir monitoring sensors. They identify industry problems, attempt to apply existing technology or develop new if necessary, assess the likelihood of success, and the ability to scale production. They seek an "early adopter" partner to help design and prove the technology. Shell is such a partner for the Raman spectrometer application to shale.

The previous companies have developed or deployed new technologies and methods to be used by others. In the next example, Hunting's business is manufacturing technologies developed by others.

Hunting PLC (London Stock Exchange)

Hunting's business is building and supplying technologies used in the well bore. It holds over 400 patents, and services the oil and gas industry with proprietary technology. Hunting leverages its manufacturing and logistics capability to make and distribute tools and equipment for NOCs, IOCs, and oilfield service companies. They manufacture to their customer's specification and schedule, providing products globally through 42 manufacturing facilities and 34 distribution centers strategically located in the heart of the major oil plays.

Hunting has grown through organic and strategic acquisitions extending its product portfolio into energetics, perforating systems, electronics, logging equipment, and high precision manufacturing platforms. Hunting's market offering establishes it as a leading manufacturer of technology.

Hunting provides manufacturing and logistical expertise for the industry. The final example is an organization which provides research expertise for the industry. Most would not classify Battelle as an oilfield service company. Nonetheless, the firm brings technology and capability to solve some of the industry's more challenging problems.

Battelle Memorial Institute (privately held - 501(c) (3) charitable trust)

Battelle Memorial Institute applies science and technology to solving "what matters most." It is the world's largest nonprofit research and development organization with broad scientific and engineering knowledge, which it can readily apply to oil industry challenges.

At any given time, Battelle is involved in a wide variety of research projects. One of Battelle's "what matters most" problems was water purification, and they were looking at ion exchange chemistry to remove contaminants. Through a serendipitous discussion on a plane, a Battelle executive and a Pennsylvania entrepreneur discussed a local problem, acid mine drainage (AMD). This resulted in Battelle's HydroFlex technology, which is designed to treat AMD to remove contaminants such as sulfate, selenium, and barium from water.

A decade later, Marcellus producers developed a need for water for hydraulic fracturing. A Pennsylvania state committee issued a white paper encouraging the use of AMD by the oil and gas industry. The entrepreneur recognized an opportunity, and HydroFlex is now being commercialized through Winner Water Services, a Battelle subsidiary, to provide treated AMD as source water for hydraulic fracturing. It is a locally available and environmentally-conscious source. There are challenges for the use of AMD regarding quantity and attached liability. But environmentally, it moves in the right direction, repurposing a waste product.

Battelle's HydroFlex technology is a reminder that solutions created for other purposes may help solve oil and gas industry problems. Companies like Battelle can provide access to a large pool of intellectual property, laboratory and test facilities, skilled experts and, perhaps just as importantly, a fresh perspective along with them.

Aerospace companies, IBM, NASA, and others also have large technology portfolios and research capability. As an industry, we should continue to explore for technology solutions wherever they exist.

Observations

As noted in the opening quote from Peter Drucker, it is hard to stop doing something when it works and is making money. However, many small and mid-cap companies survive on innovation. Some differentiate themselves through geographic advantages and local knowledge. Others invent new tools and chemicals, apply concepts from other industries, and find new uses for older technologies.

Determination and creativity can make up for what they may lack in financial resources. Smaller size brings C-level executives into the discussion which solidifies the status of the innovation in the business plan. Executive involvement also helps to secure support of other interested partners.

Successful technology companies demonstrate creativity in winning early adopters. The oil patch can be a tough place to win acceptance of a new idea, but these smaller companies have shown ingenuity in the struggle. Strategies vary. Some find willing partners; some acquire assets to demonstrate their new technology. Others apply sophisticated big data analytics to quantify their products' performance.

It is critically important to deliver value from new technology to early adopters and when successful, be able to scale the solution. Many of the people interviewed for this article recognized that success can demand hard work to find or even create the supply chain to manufacture and deliver their solution.

The industry is a high-tech business using the latest software, materials, biology, and nanotechnology to reduce environmental impact, make assets safer, and recover more hydrocarbons. It continually needs new technologies. Thank you small- to mid-cap oil field service companies for your valuable contributions. Carry on.

About the authors

Michael S. Strathman, MBA has more than 40 years of experience in the energy business as an executive and a consultant working in all phases of oil and gas; exploration and production, refining and marketing, technology, and finance.

Anthony R. Strathman, PhD has obtained a doctorate in physics, and has extensive experience in complex network research, innovative technologies, data driven analytics and exploration of large data sets.