Design Advanced For Large-scale, Economic, Floating Lng Plant

Marie M. Naklie

Mobil Technology Co.

Dallas

Mobil's large-scale, floating LNG plant design evolved to a square barge from an FPSO vessel (Fig. 1).

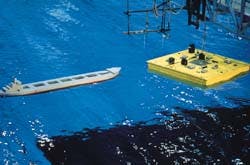

A model of the floating LNG plant undergoes wave tests (Fig. 5).A floating LNG plant design has been developed which is technically feasible, economical, safe, and reliable.

This technology will allow monetization of small marginal fields and improve the economics of large fields.

Over the past 2 decades,1-3 significant interest in floating LNG prompted examination of broad concepts, but lacking was more specific work that integrated marine and process-engineering issues.

The earlier studies did not determine if their concepts were technically or economically feasible. Additionally, they did not address large-scale applications.

Mobil Technology Co., Dallas, formed a multidiscipline team to evaluate the feasibility of floating LNG; this work has resulted in a unique floating-plant design.

Mobil's world-scale plant design has a capacity of 6 million tons/year of LNG and up to 55,000 b/d condensate produced from 1 bcfd of feed gas (Fig. 1 [24959 bytes]). The plant would be located on a large, square, concrete barge with a central moonpool.

LNG storage is provided for 250,000 cu m and condensate storage for 650,000 bbl. And both products are off loaded from the barge.

Model tests have verified the stability of the barge structure: Barge motions are low enough to permit the plant to continue operation in a 100-year storm in the Pacific Rim. Moreover, the barge is spread-moored, eliminating the need for a turret and swivel.

Because the design is generic, the plant can process a wide variety of feed gases and operate in different environments, should the plant be relocated. This capability potentially gives the plant investment a much longer project life because its use is not limited to the life of only one producing area.

Significant capital savings can be realized for grassroots developments from offshore fields. Since the floating plant will not require capital for harbor facilities, separate offshore-field processing facilities, and the field-to-shore pipelines, the project can be much more economical relative to an onshore plant.

Duplication of infrastructure is avoided by placement of all utilities, housing, warehouses, and shops on the floating plant barge.

Construction time can be 25% faster, partly because work on individual components can proceed in parallel; there is no delay for site preparation. Worldwide sourcing of modular components that can be linked together in protected waters also hastens the process. And the plant can be precommissioned in transit.

Basis

Designing a large floating LNG plant was important in order to gain economy-of-scale advantages. Since the plant can be moved when a field is depleted, small gas fields can be monetized from a large floating LNG plant by simply depleting them faster.

The potential for moving the floating plant during its life meant that the barge and topsides design had to be flexible. The barge was designed around a severe base case that would fit most of the gas fields in the Pacific Rim but not fields with high H2S or high CO2. The base case assumes a location offshore northwest Australia in 650-ft water.

The topsides are designed to handle a well stream with up to 15% CO2, 100 ppm H2S, and 55 bbl/million cu ft condensate. Flexibility was built into the design to handle a very lean or rich gas and varying levels of CO2.

Booster compression is provided should the field pressure decline below plant-inlet pressure. Field processing will be handled on the barge, and the wells will be managed from the barge. Drilling and workovers must be handled by separate rigs.

Mobil conducted initial scoping studies to establish the best design criteria for determining the floating LNG plant throughput. It was concluded that full utilization of gas turbines would provide the most efficient and cost-effective design.

The conclusion was driven by the fact that the turbines constitute a major share of the topsides costs and are the primary contributors to plant operating costs. The turbine selected was the General Electric LM6000, the largest two-shaft machine in the industry and the most efficient.

A total of 14 of these are used for the refrigerant compression, power generation, and booster compression in the 6-million ton/year case.

The result is a design which takes advantage of economy-of-scale and meets topsides, hull, and storage requirements cost effectively. The development is integrated from the wellheads, through the process, through storage, to the tankers, building on the synergy between the hull and the topsides.

And all technical challenges were met with proven technology.

The plant

Mobil developed four cases: a 3 million tons/year and a 6 million tons/year propane precooled, spiral-wound liquefaction case, and a 4 million tons/year and a 6 million tons/year single refrigerant, plate-fin liquefaction case.

Enhanced process flow diagrams, equipment lists, electrical load lists, two-dimensional layouts, and a three-dimensional computer model were developed for the cases.

The hull design requirements include the capacity to support the topsides facilities of 100,000 tons, storage capacity in excess of 2 million bbl of produced hydrocarbons, optimum motions to minimize process downtime in poor weather, relatively simple construction, and a high degree of overall safety.

Concrete was chosen for the hull material primarily for the superior low-temperature behavior of concrete, low maintenance requirements, excellent fatigue life, and improved motion characteristics due to the heavy hull weight, high mass moment of inertia, and low center of gravity.

The barge will be constructed as four small barges in a dry dock, then towed to a protected harbor for outfitting. Prefabricated LNG tanks will be brought to a dry dock and lowered into the hull prior to fabrication of the barge main deck.

The topsides will be constructed in modules and skidded onto the barge. The four barges will be post-tensioned and grouted together to form one continuous concrete structure, never to be separated. The plant is then towed to the field where it will be spread-moored with six anchor chains at each corner.

In the design, the topsides are located on four decks on the hull. The main deck is the top of the hull and is exposed to heavy seas. Therefore, no equipment is located on the main deck, except for the condensate rundown tanks which have no connections exposed to the main deck.

The spar deck is located above the main deck. The motors for all the submerged pumps in the tanks in the hull are located on the spar deck, as well as the primary topsides. The mid deck is located above the spar deck, and the top deck is located above the mid deck. The top deck is only required for a few unit operations.

Living quarters for 250 will be on the barge and, unlike most offshore developments, maintenance shops and warehouses will also be on the barge to support the operation totally. With no shops and warehouse onshore, duplication of infrastructure will be eliminated.

In addition, reliability will be increased because operations will not have to wait for parts. Equipment has been standardized to minimize warehouse and maintenance requirements. Only a small shore base will be needed for helicopters and supply staging.

Detailed manning studies and operating costs evaluations revealed that operating costs for the floating LNG development will be comparable to an onshore development.

Risers located in the moonpool move well stream production from subsea wells to the inlet manifolding area. The process contains inlet separation and stabilization to handle 1 bcfd of feed gas (Fig. 2 [30905 bytes]). Gas is treated and dehydrated in two trains before progressing through the liquefaction section.

Mobil evaluated various liquefaction processes. For floating LNG, a single mixed-refrigerant process was selected. The process uses plate-fin heat exchangers, resulting in a process less vulnerable to motion.

Because the entire refrigerant loop is designed for the settle-out pressure, no refrigerant is lost when the process trips or is shut down for extended periods. This allows a faster restart, resulting in increased stream time. In addition, the single refrigerant loop has a smaller layout and is less complex.

The associated fractionation train is much smaller because it is only required for refrigerant makeup. And with the elimination of the propane-precooling loop, the quantity and risks associated with LPG storage are significantly reduced.

Safety, reliability

Safety was a major consideration throughout the design.

With all the heat requirements in the process being supplied by waste heat from the turbines and generators, no direct-fired equipment is required. This not only increases the safety of the process, it makes the plant extremely fuel-efficient.

The liquefaction process was selected with safety as a primary criterion. The equipment is arranged on the barge so that if one were to draw a diagonal line across it, the higher risk areas are on the opposite side, away from the hotel, and the lower risk facilities are near the hotel and maintenance shops (Fig. 3 [38467 bytes]).

There is a double wall around the exterior of the hull, in which ballast water, cooling water, and potable water are stored in separate compartments. This wall acts as a barrier in the unlikely event of collision.

In addition, the facility has full-containment LNG and condensate storage (Fig. 4 [38467 bytes]). A large personnel escape tunnel runs around the perimeter of the hull.

The flare system is unique in several ways. First, there is a floating flare located 1 mile from the barge designed for an emergency rate of 1 bcfd. To keep liquids out of the flare line, Mobil developed a subsea knockout drum which uses high-pressure gas to push any liquids that might collect back up to the process.

The floating flare also acts as a vent for the CO2 that is removed from the treating process. As an alternative, a CO2-injection facility can be added if needed.

On the barge's top deck are two enclosed flares to handle low pressure and cryogenic blowdown streams. These enclosed flares block noise and radiation to the rest of the plant.

Reliability was also important in the design. Spare capacity was built into all of the utilities, using the criterion that the floating LNG plant would meet or exceed the sparing philosophy of an onshore plant.

A full 100% redundancy is provided in power generation. The LM6000, the backbone of the barge, has an availability factor of 99.5%. With warehouse and maintenance shops located on the barge, parts and personnel are immediately available to facilitate repairs. And the innovative hull design is very stable for process operations and offloading.

The faster restart of the liquefaction process improves reliability. In addition, eliminating two major components of a shore development, the pipeline to shore and the field processing unit, also eliminates two more major sources of downtime.

The result is an LNG plant probably more reliable than any existing grassroots LNG plants in operation today.

Major technical challenges included motion, offloading, and CO2 treating/disposal.

Motion

The design team started with a weathervaning shipshape FPSO and progressed through many iterations to arrive at the square barge. Mobil's marine engineers performed hydrodynamic/motion analysis using the WAMIT program (developed by MIT). A sizing program was written in MATHCAD to optimize the shape for a variety of sea conditions.

Model motion tests of the 540-ft square concrete hull conducted at Texas A&M University's Offshore Technology Research Center indicated an extremely stable platform. Motion on the barge will range from less than 1° amplitude in normal conditions, to 3° in a rough storm, to 8° in a 100-year typhoon, allowing for production to continue even during rough seas.

Although loading will not be possible during a typhoon, the barge has been designed with enough storage space to handle 8 days of production.

Table 1 [16112 bytes] describes the resulting motion parameters, both predicted and measured. Hs = significant wave height, Tp = peak period, and Hmax = maximum wave height.

Fig. 5, a photograph from the model test, illustrates an offloading condition of 3-4 m significant wave height. Further model tests will be performed this year to verify towing requirements and duration.

The hydrodynamic stability of the hull was examined for a number of scenarios. For example, collision cases were analyzed for flooding of one entire side of the barge (three ballast tanks plus two corner compartments). It was found that the barge was stable, and only a 5° tilt resulted.

The superior motion performance of the hull makes offloading possible more than 95% of the time, reduces wear and tear on the risers, and results in very stable process operations.

In order to ensure smooth process operations in rough weather, even during a typhoon, all treating towers and fractionators were designed with packing rather than trays. And to compensate for the potential effect of motion, 10-20% additional packing height was included.

The liquid distributors were specifically designed to offset any impact from motions. And the ballast system was designed to prevent any permanent tilt, even during offloading.

Offloading

Loading of LNG from the barge to the LNG shuttle tanker is a critical operation. The design loading rate is 10,000 cu m/hr. The system provides two independent passages: one for offloading the refrigerated product and one for the boiloff vapor return.

In order to be able to offload LNG more than 95% of the time, the designated tankers will be equipped with both tandem manifolding for loading from the plant and side-by-side LNG manifolding for offloading in port.

The floating LNG plant will have mechanical loading systems located at opposite corners of the barge (Fig. 6 [26864 bytes]). The two systems will allow the shuttle tankers to load, regardless of wind direction.

Both cryogenic floating and hanging hose/piping options are also being investigated, as alternatives to the mechanical system.

CO2 treating, disposal

A key processing goal was elimination of all fired heaters in the process. This meant that all of the reboiler requirements for the treating unit had to come from waste-heat recovery.

Finding a treating solvent with minimal heat requirements, therefore, became the major selection criterion for the high-CO2 case. A split-flow amine process was selected, in addition to maximizing cross exchanger area and minimizing regeneration pressure.

Once the CO2 was removed, disposal became a major challenge. Dispersion models revealed that venting large quantities of CO2 at the barge was not desirable.

The current design includes a booster compressor on the acid gas to transport the CO2 to the floating flare as purge gas, and the flare is designed to stay lit with this mixture. A CO2-injection system was designed as an alternative.

Acknowledgments

The author would like to thank Mobil Technology Co. for granting permission to publish this article. She would also like to acknowledge the members of her Floating LNG Plant Team for developing this innovative technology: Subir Bhattacharjee, Dave Garrett, Ed Grave, George Gu, Kailash Gulati, George Hoff, Joe Jeffery, Roy Johnson, Carl Kinney, Raul Lopez, Jin Mok, Roy Rolph, Harvey Schulz, Jon Sonka, Walt Spring, Bert Sweetman, John Weeks, and Kris Yost of Mobil Technology Co., Dallas. Also, Tony Urbanelli of Mobil Shipping & Transportation, Fairfax, Va., and Cary Iverson of Mobil New Exploration & Producing Ventures, Dallas.

References

1. Backhaus, H., and Brumshagen, W., "LPG and LNG Production Plants Installed on Offshore Platforms," presented at Offshore China '83, November 1983. 2. Buchanan, R.H., and Drew, A.V., "Techno-Economic Case for Offshore LNG," presented at the offshore Technology Conference, Houston, May 1-4, 1989. 3. Knott, T., "LNG Coming in from the Cold," Offshore Engineer, September 1989.

Marie M. Naklie is team leader of Mobil's Floating LNG Plant Team in Dallas. She has 24 years with Mobil, specializing in LNG, gas processing, debottlenecking, and troubleshooting primarily in the international sector. Naklie holds a BS in chemical engineering from Mississippi State University and is vice-chairman of the North Texas Chapter of the Gas Processors Association.

Copyright 1997 Oil & Gas Journal. All Rights Reserved.