Special Report: Refiners processing heavy crudes can experience crude distillation problems

Refiners will process increasingly heavier crude slates during the next 10 years. A majority will originate from the Orinoco oil belt bitumen upgraders in Venezuela and the Athabasca tar sands region of northern Alberta.

Even blended with lighter crudes, these lower-gravity blends will require crude-unit process flow scheme and equipment design changes to meet profitability objectives.

This article addresses crude distillation unit (CDU) problem areas and identifies specific sections requiring investment to maintain profitability throughout a 4-5 year run length for refiners processing heavy crudes.

Some heavy crudes are blends of 6-8° API bitumens combined with hydrotreated lighter products from bitumen upgraders.

The blended lighter products that help produce synthetic crudes generally distill in the atmospheric column leaving a very heavy 6-8° API feed to the vacuum unit. CDUs must operate at increased severity to maintain product cut points and qualities.

Heavy crudes are more difficult for the CDU to process. Historically, refiners processing heavier crudes have had problems maintaining:

- Crude charge rate.

- Product yield and quality.

- Unit reliability.

CDU processing difficulties

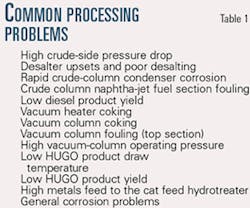

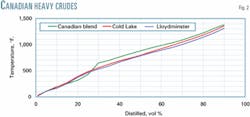

Table 1 shows some specific problems refiners face when processing heavy crude blends.

Heavy crudes have higher viscosities, some have higher salt content, several have high naphthenic acid content, and they are all more difficult to distill than lighter crude blends. Some upgrader crudes also have lower thermal stability than conventional crudes and higher fouling tendencies due to the increased likelihood of asphaltene precipitation.

Processing difficulties can result from flow schemes and equipment designs that may have worked well with light crudes, but are not compatible with the heavy crude characteristics. Revamps to process heavy crudes must carefully consider the flow scheme and equipment design in order to maintain crude charge rate, product yield and quality, and unit reliability.

Crude blends with gravities <22° API require sufficient cold exchanger train preheat to achieve efficient desalting, which typically requires a desalter temperature between 270° and 300° F.

The desalter must separate the emulsion into low-salt crude and oil-free water.

With a heavier crude feed, the desalter temperature can decrease by 30° to 40° F., if no additional surface area is added to the cold exchanger train. The desalted crude's salt content can increase dramatically if the temperature is too low. Many heavy crudes such as Zuata or Merey can have high salt contents depending on production field operations; therefore, good desalter performance is critical. Poor cold exchanger train designs often cause low desalter temperatures, poor salt removal, and periodic upsets that send large quantities of brine to the atmospheric heater and column.

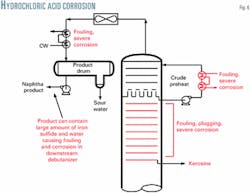

High chlorides to the atmospheric heater generate large quantities of hydrochloric acid (HCl). Severe fouling in the crude column's top, rapid fouling and corrosion in the atmospheric condenser system, and severe overhead line corrosion often reduce crude runs and unit reliability.

Most heavy crudes have higher viscosities, a condition that makes increasing or maintaining crude charge rate a challenge.

Higher viscosity reduces the crude charge-pump developed head, increases exchanger network pressure drop, and lowers heat-transfer coefficients throughout the cold preheat train. Crude charge rate, atmospheric column heat removal, and desalter temperature are all adversely affected.

Many heavy crudes contain more vacuum gas oils. Refiners, therefore, often increase the atmospheric tower bottom (ATB) product cut point to stay within the vacuum column diameter limits. As ATB cut point increases, however, vacuum unit feed gets heavier resulting in higher vacuum tower bottoms (VTB) yield.

Increasing the vacuum heater outlet temperature can sometimes offset a higher ATB cut point. But many refiners have existing heater design problems that prevent a higher outlet temperature without shortening heater run length. Refiners, therefore, must optimize ATB product cut point to maximize heavy vacuum gas oil (HVGO).

An optimized ATB cut point is about 700° F. for heavy Venezuelan Merey, BCF-17, and Zuata crudes, assuming no downstream equipment limits.

Most refiners and designers adjust ATB cut point vs. crude heater outlet temperature only.

Other parameters are, however, more effective in adjusting ATB cut point: minimized atmospheric column flash-zone pressure, minimized percent overflash, and optimized ATB stripping efficiency.

This maximizes diesel recovery and reduces vacuum ejector condensable load, which permits lower vacuum column operating pressure and helps maintain HVGO product cut point.

Maintaining HVGO cut point is a significant challenge with heavier crude blends. Most refiners lose 40° F. or more in HVGO product cut point when switching to a heavy crude diet. Maintaining cut point requires a combination of lower operating pressure, higher heater outlet temperature, reduced flash-zone pressure, lower flash-zone oil partial pressure (more heater coil steam), and improved VTB stripping. The right combination will be specific to each unit.

The combination of operating variables needed to maintain or increase HVGO cut point is more severe and can lead to rapid vacuum heater or column coking if the equipment is not carefully designed.

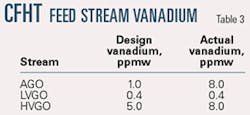

Heavy crudes have much higher microcarbon residue (MCR), asphaltenes, and metals. As mandated refinery gasoline and diesel pool sulfur specifications take effect, minimizing cat feed hydrotreater (CFHT) feed contaminants becomes more important.

In some cases, vanadium in the CFHT feed has increased from less than 1 ppm to 5-10 ppm with heavy Venezuelan crudes.1

High feed-stream contaminants can reduce run length to less than half the planned turnaround interval.

Optimizing the atmospheric column flash-zone and wash section, and the vacuum unit design can reduce CFHT feed vanadium by 30-40%.

Heavy crude properties

True boiling point (TBP) distillation curve, contaminants (MCR, asphaltenes, and metals) distribution, viscosity, salt content, and total acid number (TAN) increase CDU operating severity and make heavy crudes inherently more difficult to process.

Venezuelan heavy crudes include Merey, BCF-17, Zuata, BCF-22, and Laguna Blend 22. US refiners are also processing large volumes of Mexican Maya crude. Heavy Canadian crudes include Cold Lake blend, Lloydminster (LLB), and tar sands blends.

Only a few refiners can process these crudes neat.

Other refiners that increase their heavy crude percentage also face many of the same processing challenges.

TBP distillation

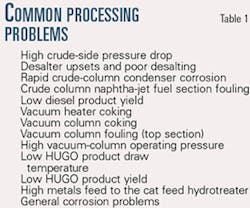

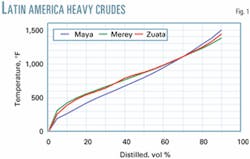

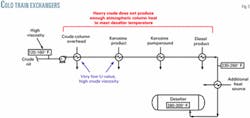

Accurate crude TBP curves are essential when CDUs are revamped to process heavy crude feeds. Figs. 1 and 2 show TBP curves for selected heavy Venezuelan and Canadian crudes.

TBP curves are typically generated from ASTM D2892 and D5236 tests. Some refiners now use high-temperature simulated distillation (HTSD) to characterize the whole crude. Significant differences between the two methods become more pronounced as crude API gravity decreases.2

We found that HTSD curves provide the best characterization of product yields in the 650+° F. portion of the distillation curve.

We reviewed several comprehensive test runs on crude units processing heavy crudes and compared synthesized whole crude TBP curves generated from product stream HTSDs, whole crude HTSDs, and crude assay TBP curves generated from ASTM D2892 and D5236 tests.

During a CDU revamp to process heavy crude, the designer must accurately characterize crude feed; otherwise, predicted product yields, operating conditions, and equipment design may be flawed.

Inaccurate feed characterization of crude's heavy end has resulted in poor revamp yields and coked vacuum column wash beds.

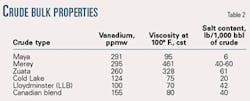

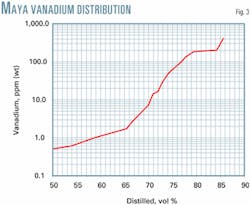

Whole crude properties

Table 2 shows vanadium, viscosity, and salt content for some heavy crudes. Fig. 3 shows the vanadium distribution curve for Maya crude.

Some vanadium compounds begin to vaporize at 925-950° F. TBP temperatures; therefore, HVGO vanadium will rise as cut point increases.3

Improved HVGO fractionation lowers vanadium for the same TBP cut point.4 A properly designed vacuum unit can reduce HVGO vanadium content by 30-50%.

Table 3 shows how CFHT feed vanadium content can increase for a poorly designed CDU heavy crude revamp. High ATB entrainment into the atmospheric gas oil (AGO) and high entrainment and poor fractionation in the vacuum unit caused the high CFHT feed vanadium content.

ATB and VTB produced from Maya crude will have nearly 550 ppm (wt) and 900 ppm (wt) vanadium, respectively. Operators must therefore eliminate all crude and vacuum column entrainment to minimize CFHT feed contaminants.

Because heavy crudes have more vacuum gas oils, vacuum column vapor velocities increase. Poorly distributed vapor entering the wash section creates high localized velocities that exceed the maximum limit for effective VTB deentrainment.

Some refiners have seen HVGO MCR and vanadium levels greater than 1 wt % and 10 ppm (wt), respectively, when processing 22° API gravity crudes.

Well designed flash-zone vapor horn and internals reduce entrainment; both are critical to minimize CFHT feed contaminants.5

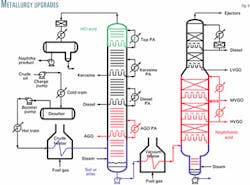

Some heavy crudes require metallurgical upgrades to higher-alloy materials due to high naphthenic acid (Table 4), high sulfur, and high crude-column overhead system chloride levels (Fig. 4). Crudes with a total acid number (TAN) of 2.4 will produce an HVGO TAN of 3.5 or greater.6 7

Metallurgy upgrades are needed for gas oil circuits that operate between 500° and 650° F. Piping and column internal components such as beams, packing supports, and tower attachments commonly use 317L. Some refiners use 904 stainless steel in the vacuum column for cladding and internals because it has a high molybdenum content, thus making it resistant to naphthenic acid attack.

Processing tar sands crudes creates some unique challenges. These crudes can have high sediment and clay contents and some blends also have high viscosity.

Desalter operations are more difficult and there is an increased likelihood of stable emulsion formation. If desalter performance deteriorates, the corrosion rate in the atmospheric column overhead system may increase and cause reliability problems.

Maintaining crude charge rate

Revamp process flow schemes must account for the inherent crude hydraulics and preheat dilemma associated with processing heavy crudes while maintaining unit reliability.

Higher-viscosity heavy crudes reduce the crude-charge-pump developed head and can also increase exchanger fouling.

Circumventing hydraulic limits to achieve a desired crude feed rate can be expensive; therefore, a revamp must consider crude hydraulics early in the process to ensure there is sufficient capital to achieve processing objectives.

Crude charge hydraulics are not generally evaluated thoroughly enough until late in detailed engineering when they can result in scope growth, additional expenditure, or scope rationalization.

Crude charge rate will often decrease if preheat train modifications are not made. With heavy crudes, cold-exchanger-train heat transfer decreases because there is less heat available from the atmospheric column pumparounds and products.

These exchangers also have lower heat-transfer coefficients due to higher crude viscosity. Additional cold-train-exchanger surface area is needed to meet desalter temperatures necessary for efficient desalting.

To lower the cold-train pressure drop at the expense of crude velocity, refiners commonly install new exchangers parallel to existing exchangers or reduce the exchanger bundle tube passes on existing exchangers.

This approach causes increased exchanger fouling, which decreases heat-transfer coefficients and increases pressure drop.

For example, cold-train exchangers processing 100% Merey or BCF-17 operate in the laminar flow regime and have service heat-transfer coefficients as low as 12 btu/hr-sq ft-°F.

An alternate approach is adding exchangers in series with existing exchangers (Fig. 5), which minimizes fouling and increases pressure drop. Heavy crude revamps typically require larger charge pump motors and impellers and sometimes pump replacement.

New exchanger bundles are typically designed for higher maximum allowable working pressure (MAWP) to meet cold-train charge hydraulics. Designers must also evaluate pipe flange and exchanger pressure ratings for the higher head pumps. Several heavy-crude revamp designs included very little pressure drop available on the desalter pressure-control valve and crude-heater-pass balancing valves for start-of-run operation.

When exchangers are clean, design crude-charge rates were possible; however, as the exchangers foul, pressure drop increased and crude rate was reduced.

In some designs, the operator had to open exchanger bypasses to meet design charge rates when the exchangers fouled. This generally allows a higher crude rate, but it also lowers the temperature at the desalter, reduces atmospheric-column heat removal, raises atmospheric-column operating pressure, and increases product-rundown temperatures.

When revamping a preheat train to process heavy crude, the designer must use accurate viscosities, allow sufficient pressure drop allowance for fouling, and correct pump head-flow and efficiency curves for viscosity effects.

Product yield, quality

Many heavy crude blends contain less total atmospheric-plus-vacuum-column distillates and more ATB and VTB; therefore, high recovery of these distillates is important.

A well-designed crude unit can recover more distillates than inadequate process and equipment designs. In one case, for the same heavy crude a poorly designed flow scheme and equipment flaws yielded 20 vol % atmospheric distillates and 80 vol % ATB, whereas a proper design yielded about 33 vol % atmospheric distillate and 67 vol % ATB.

Processing heavier crudes can lower diesel product recovery, increase diesel boiling-range material in the CFHT feed, reduce HVGO recovery, increase CFHT contaminants, and increase <1,000° F. boiling-range material in the coker feed.

Higher heater temperature, lower atmospheric and vacuum-column operating pressures, lower atmospheric column overflash,8 improved wash-section efficiency, and better ATB-VTB stripping are needed9 to maintain product yield and quality.

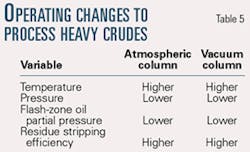

Table 5 shows operating changes needed to maintain atmospheric and vacuum column ATB and VTB cut points.

Heavy crudes are difficult to vaporize in the crude heater alone. Diesel product cut point may vary 30° to 80° F. due to low diesel-AGO internal reflux, high column pressure, low pumparound-heat removal, high overflash rates, and ineffective stripping section performance.

Low diesel recovery causes a high feed rate to the CFHT or FCC and may limit refinery crude rate when these units are operating at maximum capacity.

Because heavy crudes contain vanadium compounds that distill in the HVGO-product boiling range, increasing HVGO-product cut point will increase metals. The rate of increase is directly related to the process and equipment design.

Efficient VTB stripping lowers HVGO vanadium; yet most vacuum units are designed without VTB stripping. The few units that include a stripping section have tray efficiencies less than 10-15% due to poor tray design. These stripping sections can require higher steam rates, which increase condenser and ejector system capital and operating costs.

Reliability

Unit reliability means the unit can meet a targeted run length without significant deterioration in charge rate, product yield, or product quality. Poor reliability results in unscheduled shutdowns, significantly lower product yields and quality, or reduced unit charge rates.

Heavy crudes diminish unit reliability due to chronic heater coking,10 condenser corrosion, crude-column tray fouling, or poor desalter operations.

Correcting these deficiencies requires capital investment; otherwise, realistic run lengths may only be 1-2 years vs. 4-5 years that many refiners target. Refiners must always balance revamp capital investment against run length.

Heavy crude viscosity can cause poor desalter performance. As desalter temperature drops, oil-water separation becomes problematic and the desalted-crude salt content increases. Some refiners processing heavy crudes have had to switch from series to parallel desalter operation to eliminate oil-water separation problems.

Single-stage desalting removes 90-95% of crude salt; desalted crudes may have salt contents of 3-6 lb/1,000 bbl. This high chloride content results in fouling and corrosion in the crude-column overhead condenser and an increased likelihood of column tray fouling (Fig. 6).

Revamp process design

Crude-unit process flow schemes should focus on crude properties, processing objectives, and design fundamentals. Heavy oil is inherently more difficult to vaporize because there is less light material in the feed.

Crude-unit designs must optimize ATB cut point to balance overall unit performance because it influences crude and vacuum column operations. The relationship between ATB and VTB cut points are complex and refiners must evaluate the columns and ancillary equipment as a single system.11

With a lower ATB cut point, there is less atmospheric flash-zone vapor available to provide pumparound and product heat to the cold exchanger crude preheat train. As diesel and AGO materials shift to the vacuum tower, less high-temperature heat is available for crude preheat.

Diesel and AGO pumparound and product temperatures are about 550° F. and 625° F., respectively. LVGO draw temperature is only about 330° F.; therefore diesel and AGO product yielded in the vacuum column provides little or no preheat. A lower HVGO product draw temperature can also result due to a lighter HVGO product.

Maximizing diesel recovery is important when crude rate is limited by CFHT or FCC unit capacity. This requires optimum atmospheric column diesel-AGO fractionation, ATB stripping, and AGO product stripping.

Good diesel-AGO product fractionation requires adequate reflux rate (liquid-vapor ratio), 8-10 trays, and good tray efficiency. Most atmospheric columns wider than 16 ft in diameter will use four-pass trays. These large-diameter towers have low weir loadings (gpm/in. weir) and the tray efficiencies can be low. Low reflux and tray efficiency dramatically reduce diesel yield.

An AGO pumparound increases crude preheat; however, if the ATB cut point is only 700° F., there is not enough vapor from the atmospheric column flash zone to provide sufficient internal reflux in the diesel-AGO fractionation section to allow heat removal from an AGO pumparound.

Operating with an AGO pumparound should be based on crude TBP distillation, acceptable diesel-AGO fractionation, and ATB cut point target, not standard design practices.

The vacuum-unit design depends on the HVGO product cut point target, vacuum heater design, crude vanadium distribution, and other detailed equipment design issues. HVGO product cut points are typically less than 975° F. when crudes with gravities less than 24° API are being processed.

A dry vacuum unit design uses no steam in the heater and does not have a stripping section. Maintaining cut point is difficult even with a well-designed unit using coil steam, but a dry vacuum unit simply cannot operate reliably at cut points greater than about 950° F. when processing Merey, Zuata, or BCF-17 crudes.

A heater without coil steam must operate at only 760-770° F. to avoid rapid coking from heavy crudes. HVGO product TBP cut points >1,000° F. require a heater outlet temperature of 795-800° F., low flash-zone oil partial pressure, and good VTB stripping.

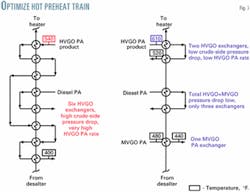

Heavy crude increases total LVGO and HVGO pumparound duty requirements because more VGOs are yielded. A two-product vacuum column will have a high HVGO pumparound duty at a relatively low temperature of about 480-540° F. Increasing vacuum unit heat input requires more surface area and more HVGO pumparound capacity to remove the added heat.

Increasing HVGO pumparound duty typically requires increasing the number of exchangers in series because the log mean temperature difference is so low.

One refiner used six exchangers in series in the hot preheat train. Exchanger network design must address the increased pressure drop caused by additional exchangers.

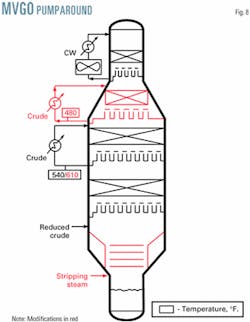

This refiner can alternatively include an extra pumparound. A portion of the HVGO pumparound heat shifts to an MVGO pumparound. This increases the HVGO pumparound temperature to >600° F. and reduces the hot train preheat exchangers from six to three (Fig. 7).

When crude hydraulics are tight, a third pumparound can help alleviate crude bottlenecks. It can also reduce the required HVGO pumparound circulation rate to stay within existing pump and piping limits. A third vacuum-unit pumparound often results in the lowest overall cost solution (Fig. 8).

Revamp equipment design

Maximizing heavy oil vaporization, minimizing product contaminants,12 and maintaining an acceptable run length requires fundamentally sound equipment design.

Vacuum heater, ATB and VTB stripping, and atmospheric and vacuum wash section designs influence unit performance.13 14

Refinery vacuum heaters need to operate at outlet temperatures between 790° and 800° F. while meeting run-length targets.15

Maximized ATB stripping efficiency requires adequate stripping steam, maximum trays, and maximum tray efficiency. VTB stripping and vacuum heater coil steam should balance with column operating pressure.

Atmospheric and vacuum column flash-zone vapor horn and wash sections should eliminate entrainment and the vacuum column needs to fractionate HVGO product to reduce the TBP curve 95%-EP tail. F

References

- Leroy, Charles F., et al., "Hydrotreating Vacuum and Coker Gas Oils from Heavy Venezuelan Crudes for FCCU Feedstocks," NPRA Annual Meeting, San Antonio, Mar. 17-19, 1991.

- Villalanti, D.C., et al., "Yield Correlations Between Crude Assay Distillation and High Temperature Simulated Distillation (HTSD)," AIChE Spring National Meeting, Houston, Mar. 9-13, 1997.

- Golden, S.W., Craft, S., and Villalanti, D.C., "Refinery analytical techniques optimize unit performance," Hydrocarbon Processing, November 1995.

- Golden, S.W., and Martin, G.R., "Controlling Vanadium from High Metals Crude Oils," NPRA Annual Meeting, San Francisco, Mar. 18-20, 1995.

- Barletta, T., and Golden, S.W., "Refiners must optimize FCC feed hydrotreating when producing low-sulfur gasoline," OGJ, Oct. 14, 2002, pp. 54-63.

- Hopkinson, B.E., and Penuela, L.E., "Naphthenic Acid Corrosion by Venezuelan Crude," NACE Paper No. 502, 1997.

- Tebbal, S., et al., "Critical Factors Affecting Crude Corrosivity," Petroleum Technology Quarterly, Spring 1997, pp. 85-91.

- Golden, S.W., and Binkley, M.J., "Crude-tower modification stabilizes operations," OGJ, July 30, 1984, pp. 197-204.

- Hanson, D.W., and Martin, M., "Low-capital revamp increases vacuum gas oil yield," OGJ, Mar. 18, 2002, pp. 70-82.

- Martin, G.R., and Barletta, T., "Vacuum Unit Fired Heater Coking- Avoid Unscheduled Shutdowns," Petroleum Technology Quarterly, Spring 2001, pp. 123-27.

- Martin, G.R., "Vacuum Unit Equipment Design Influences Key Operating Variables," Petroleum Technology Quarterly, Summer 2002, pp. 123-27.

- Hanson, D.W., Lieberman, N.P., and Lieberman, E.T., "De-entrainment and washing of flash zone vapors in heavy oil fractionators," Hydrocarbon Processing, July 1999, pp. 55-60.

- Golden, S.W., Lieberman, N., and Martin, G.R., "Correcting design errors can prevent coking in main fractionators," OGJ, Nov. 21, 1994, pp. 72-80.

- Golden, S.W., "Troubleshooting Vacuum Unit Revamps," Petroleum Technology Quarterly, Summer 1998, pp. 107-13.

- Barletta, T., "Why Vacuum Unit Fired Heaters Coke," Petroleum Technology Quarterly, Autumn 2002, pp. 123-27.

The authors

Steve White is a chemical engineer for Process Consulting Services Inc., Houston. He has more than 25 years' experience in process design of refinery revamps and grassroots units including crude and vacuum, FCC, hydrotreater, alkylation, butamer, reformers, and others. White previously worked as refinery technology manager for Jacobs Engineering Group Inc. and as technical service engineer for UOP LLC and Atlantic Richfield Co. He holds a BS in chemical engineering from Rice University and is a registered professional engineer in Texas.

Tony Barletta is a chemical engineer for Process Consulting Services Inc., Houston. His primary responsibilities are conceptual process design and process design packages for large capital revamps. Barletta previously worked as a production planner and process specialist for BP Oil Co.'s Alliance refinery and as a process engineer for Hess Oil Virgin Islands Corp. He holds a BS in chemical engineering from Lehigh University.