New slimhole, rotary-steerable system drills first field test

Shell UK Exploration & Production (Shell Expro) and Schlumberger Oilfield Services announced in April that they had successfully field tested a 43/4-in. slimhole rotary steerable drilling system in the North Sea Brent Delta field, a test they believe to be a first.

The rotary-steerable system, which Schlumberger calls the PowerDrive Xtra 475, drilled 2,377 ft of 61/8-in. wellbore in 43.5 hr and achieved an average penetration rate of 67 fph (OGJ, May 13, 2002, p. 8).

Given the complex well profile, requiring 3D steering to intersect multiple targets, the drilling method saved 8.42 days compared to drilling a typical 61/8-in. wellbore section, according to the companies in a press statement.

They also report that the tool yielded excellent steering response and hole quality, and they were able to complete the job in a single run.

Rotary steerables

The petroleum industry performs most directional drilling for oil and gas wells by sliding the drillstring, using mud motors and bent or adjustable subs, to change the wellbore's path or direction.

Limitations in this conventional process can cause irregularly shaped well paths, restrict distances that operators can drill, and limit the success of accurately reaching reservoir targets.

These limitations stem from hole cleaning difficulties, with cuttings buildup around the stationary drillstring that can result in stuck drill pipe. Excess friction between the wellbore and the drillstring restrict sliding distances.

Developed in recent years, rotary-steerable systems allow operators continuously to rotate the drillstring while steering, which produces a faster, more controllable drilling system that results in a smoother, cleaner, and longer wellbore.

System design, function

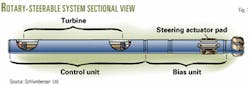

The rotary-steerable system used for the Brent Delta field test consisted of a short, 12.5-ft near-bit assembly made of two principal components, the bias unit and the control unit (Fig. 1).

Connected directly to the drillbit and constantly rotating at bit speed, the bias unit applies lateral force to the drillbit.

The control unit, a roll-stabilized platform located within a nonmagnetic collar, links mechanically with the bias unit. It contains turbine-powered electronics and sensors that set the direction and magnitude of the force vector applied to the bit by the bias unit.

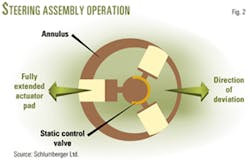

Fig. 2 illustrates operation of the rotary-steerable system. The bias unit's three exterior pads maintain constant contact with the formation with force from internal, mud-powered actuators. A three-way disc valve controls mud flow to the actuators.

When deviation is required, each actuator extends in sequence against the side of the hole opposite the intended bias direction as the bias unit rotates at bit speed. The bias unit pads extend and retract once each revolution of the bit, in a smooth and continuous action (Fig. 2).

This rotary-steerable design contrasts sharply with other systems that employ nonrotating sleeves as reference for toolface orientation.

When no deviation is required, technicians put the rotary-steerable system in neutral mode by rotating the disc valve stator relative to the high side, which causes the pads to push in every direction and effectively cancel each other.

Crews change the system's directional programming from the surface while drilling using mud-pulse sequences. A surface computer system monitors the pulses and displays the new setting for confirmation.

With wellbore inclination and azimuth measured 7.9 ft behind the drillbit, an electromagnetic noncontacting link from the rotary-steerable system's control unit to the measurement-while-drilling (MWD) unit provides telemetry for transmitting the data to surface.

The real-time link enhances operator's ability to drill demanding well profiles, according to the published reports.