Girassol, first Angola Block 17 deepwater field to produce

Girassol field, discovered in 1996, came on stream on Dec. 4, 2001; TotalFinaElf SA says production in February 2002 reached 200,000 bo/d from eight wells.

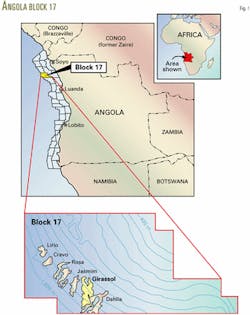

Angola Block 17 has 10 discoveries that TotalFinaElf expects to develop over the next decade. Girassol, Portuguese for "sunflower," is the first field to begin producing in this deepwater block. It lies in 4,600 ft of water, about 210 km northwest of Luanda, Angola.

Sonangol, the Angola state oil company, holds the concession for the field, which is operated by TotalFinaElf E&P Angola (40%) for partners Esso Exploration Angola (Block 17) Ltd. (20%), BP PLC (16.67%), Statoil (13.33%), and Norsk Hydro AS (10%).

TotalFinaElf estimates that the project will cost $2.8 billion after completion of the drilling and connection of the remainder of the planned 36 wells in the project

Block 17

The 10 discoveries in Block 17 are: Girassol in March 1996; Dalia in August 1997; Rosa and Lirio in 1998; Tulipa, Orquidea, Cravo in 1999; and Jasmim and Perpetua in 2000. All fields are named after flowers. Fig. 1 locates six of these discoveries.

TotalFinaElf estimates that these discoveries contain 3.5 billion bbl of recoverable oil in unconsolidated Miocene and Oligocene sands that are about 1,000-2,000 m below the mud line. It says the Oligocene sands contain a lighter 32° gravity, sweet crude, while the Miocene sands have heavier, 22-23° gravity crude with some sulfur.

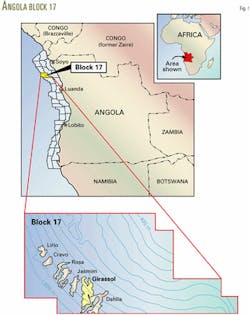

The next field in the block after Girassol that the company expects will be on stream is Jasmim, formerly known as the Girassol C reservoir. Development plans include connecting subsea completed wells to the Girassol FPSO and starting production in second half 2003. It plans to drill five producing and five injection wells to develop Jasmim.

Rosa, Lirio, and Cravo are the other Oligocene discoveries on which TotalFinaElf has conceptual studies for connecting these fields to the Girassol FPSO (Fig. 2). The furthest tie-in from Lirio will be about 30-40 km in length.

The Dalia discovery, southeast of Girassol and larger than Girassol, is one of the fields containing heavier Miocene oil. TotalFinaElf indicates the project is awaiting approval from the Angolan authorities and needs to be sanctioned internally within TotalFinaElf before the contract tendering stage can be fully launched.

Its plans call for the Dalia FPSO to be larger and capable of handling up to 240,000 bo/d, with a planned production plateau of 225,000 bo/d. Other specifications for the FPSO include a 400,000 b/d total liquid processing rate, a 410,000 bw/d injection rate, a 8 million cu m/day gas handling rate, and a 2 million bbl oil storage capacity.

The topsides composition and weight will be different than for the Girassol FPSO because Dalia's heavier oil requires more complicated process equipment.

Dalia's base-case development scheme includes 67 subsea wells, consisting of 34 producers, 30 water injectors, and 3 gas injectors, but TotalFinaElf says additional studies may alter the final number of wells drilled.

The base case also calls for six well templates for production, with wells completed with horizontal trees. Production will flow through 40 km of 12 in. flowline loops into two riser towers. The proposed injection system includes 40 km of 10-in. water injection lines and 8 km of 12-in. gas injection lines.

The company expects Dalia to begin producing by yearend 2005 and, later, may connect the Dalia FPSO to the other Miocene discoveries-Tulipa, Orquidea, and Perpetua.

Girassol FPSO

The Girassol FPSO (Fig. 3) is world's largest, according to TotalFinaElf. The FPSO weight is as follows:

- Hull-45,000 tons.

- Living quarters-2,200 tons.

- Piping and equipment-4,080 tons.

- Hull appurtenances-3.300 tons.

The FPSO supports a 23,500-ton dry weight processing topsides that can handle 200,000 bo/d and a total liquid rate of 300,000 b/d.

Mar Profondo Girassol, a joint venture between Bouygues Offshore and Stolt Offshore SA, provided the FPSO.

Hyundai Heavy Industries in Korea completed the FPSO hull in March 2001 and also built the topsides. J. Ray McDermott Inc.'s Jebel Ali yard in Dubai interfaced the hull and topsides. TotalFinaElf says the FPSO arrived fully commissioned off Angola in mid-July 2001.

The FPSO is 300-m long by 60-m wide by 31-m high and can store 2-million bbl of oil. It is moored between the Girassol and Jasmim fields.

Because of the benign environment off West Africa, the FPSO is spread moored in contrast to the heavier turret-type mooring systems common in such harsher weather environments as the North Sea and off Brazil. The spread mooring includes 16 lines, 4 on each corner.

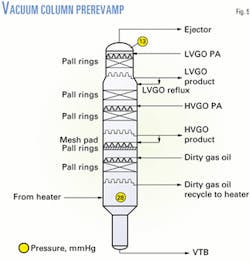

The processing equipment on the FPSO includes the largest membrane desulfurization unit in the world (Fig. 4), according to TotalFinaElf. The unit can treat 390,000 b/d of seawater that will be injected into the producing reservoir for pressure maintenance.

With the reservoir at the bubblepoint pressure, TotalFinaElf will use both water and gas injection to maintain reservoir pressure.

The desulfurization membranes remove sulfate from the seawater to prevent BaSO4 formation in the reservoir and wells. The sulfate unit has 480 tubes with 2,880 membrane filters to 5 mm size. To provide cold water, the seawater is drawn from casing run to about -90 m subsea.

TotalFinaElf expects water injection into two wells to start at the end of this month.

Also for pressure maintenance and to avoid flaring of gas, the facilities include two trains of five-stage compression that can handle 8 million cu m/day (280 MMcfd). Of this 8 million cu m/day, the plans include using 1 million cu m/day for fuel with the rest being injected at 285 bar (4,130 psi).

The initial producing GOR of the field is 560 scf/bbl.

TotalFinaElf says after gas injection started in February 2001 into one well, no produced gas will be flared.

All gas belongs to Sonangol under the contract terms. It indicates a project has been proposed for the field's later stages that will install a gas pipeline to shore to a proposed LNG plant in Angola. If this is the case, it expects to covert the two gas injectors to water injectors.

The process train on the FPSO includes three-stage separation and desalting vessels.

For supplying power, the FPSO has three 25-Mw generators for a total power generating capacity of 69 Mw. The equipment on the processing deck also includes waste-heat recovery units, burners for generating flue gas for use as an inert gas blanket for the storage tanks, and a methanol system for use during well start up and flow interruptions.

Fig. 5 shows the equipment arrangement of the process deck.

The FPSO has a distributed control system (DCS) for monitoring and controlling the wells and processing equipment.

TotalFinaElf says the normal manning level of the will be a crew of 120-140.

Girassol completions

The development scheme includes 23 producing wells, 14 water injection wells, 2 gas injection wells, five 8-in. production loops with a pigging system, and five 10-in. injection lines.

TotalFinaElf expects to produce up to 35,000 bo/d/well with conventional or highly deviated wells completed with 51/2-in. tubing and sand-control measures. It may recover as much as 725 million bbl of oil from the field.

Drilling commenced in May 2000 and plans call for drilling to continue continuously to 2003, with two drillships, Pride of Africa and Pride of Angola.

Pride International Inc. owns 51% of these drillships in a joint venture partnership with Sonangol.

These two dynamically positioned drillships have been outfitted for both drilling and completing the Girassol wells. The drillships can run subsea wellheads, and well to manifold jumpers and umbilicals. They also have space to house gravel pack and frac-pack pumps and bins.

Drilling times have been reduced significantly since development drilling started, decreasing to below the target of 50 days for Well GIR112 (Fig. 6).

Drilling includes a mineral oil-base mud, and because the reservoir sands are unconsolidated, the wells have been completed with screens in horizontal wells and with frac packs in the less deviated wells.

By February, 14 wells had been drilled and completed with subsea trees. Also seven manifolds had been installed. FMC Energy Systems provided the guidelineless, electro-hydraulically controlled subsea trees and manifolds.

The development scheme includes two subsea trees connected to most of the manifolds and two manifolds connected to each of the five flowline loops. The manifolds sit on suction anchors.

Rigid jumpers connect the subsea trees to the manifolds. TotalFinaElf says these are less costly than flexible connectors.

Bundled flowlines connect the subsea manifolds to three, 1,350-m high, self-supporting, insulated riser towers that connect the flowlines to the FPSO. Each 75-cm (30 in.) diameter bundle includes two flowlines inside syntactic foam along with a 2-in. service line. TotalFinaElf expects the bundle to maintain the crude at 40° C. Without the insulation, it says that seawater temperature of 4° C. would cause the paraffinic Girassol oil to become too viscous to flow.

TotalFinaElf had the bundles assembled north of Luanda in Soyo. It used a bottom tow method to transport the bundles to the field.

The riser towers house four production, two injection lines, four gas lift lines, and two service umbilical lines. The gas-lift lines deliver gas to the foot to the risers to prevent slugging.

The towers, anchored to the sea floor with a suction pile, have a 40-m high, steel buoyancy tank, 50 m below the sea surface to keep them vertical. The towers connect to the FPSO through flexible jumpers and to the flowlines by jumper spools.

TotalFinaElf had the riser towers fabricated and built in Lobito, south of Luanda. It then had them towed on a 600-km route to the Girassol field for upending and installation.

Crude export

Crude export includes a novel concept of using a steel pipe with buoyancy. Two 1.5 mile, 16-in. flowlines connect the Girassol FPSO to an unloading buoy. The lines are suspended in 45-550 m water depths with centrally positioned buoys in a W-shaped configuration.

Typically the FPSO will offload to 1-million bbl tankers. Through mid-February, six cargoes had been exported.

The FPSO has 24, 650 cu m/hr cargo pumps and 3, 2,000 cu m/hr booster pumps that result in a maximum offloading rate of 6,000 cu m/hr.

TotalFinaElf estimates that it takes less than 36 hr to load 1 million bbl to an export tanker

The FPSO also provides for alternative tandem offloading from the bow through 24-in. flexible hoses.