Equipment/Software/Literature

New low flow Coriolis meter, controller

This new low flow QUANTIM Coriolis meter and controller is especially suited for laboratory, research, and pilot plant applications.

A modular hardware platform using improved sensing tube geometries and optical sensing techniques now enables the unit to handle liquids and gases. This new platform allows it to measure and control flows as low as 1 g/hr and as high as 28,000 g/hr.

The firm says users will also experience better overall accuracy at the low end of the flow range because of improved zero stability.

The new Coriolis mass flow controller features a new valve that is more forgiving of variations in line pressures and reduces the chance of clogging due to a larger orifice.

The new valve also uses an all-metal valve seat, thus eliminating potential control issues associated with elastomer valve seat compatibility and swelling.

QUANTIM has no moving parts in the area where process liquids and gases flow, which helps minimize maintenance requirements. Minimal physical space is required because of its small, integrated design.

Piping and wiring during installation are simplified since the unit has fully integrated sensor, transmitter, valve, and control electronics.

Source: Emerson Process Management, Brooks Instrument Div., 407 W. Vine St., Hatfield, PA 19440-0903.

Remote monitor uses satellite for communication

A new addition to the Bullhorn family of wireless remote monitoring products uses the Inmarsat D+ satellite system for communication and is a good way to supplement installations where 100% cellular coverage is not available.

The new APM4AM-SAT satellite wireless remote monitoring device is suited for international use and enables equipment monitoring in remote locations.

It monitors cathodic protection equipment (rectifiers, test points, and critical bonds), city gates, compressors, storage tanks, pumping stations, pressure, flow, and temperature.

In addition to monitoring inputs from equipment, the unit provides automatic notifications of alarm events via voice notification, fax, page, and-or email. With secure access, data can be viewed on the internet from anywhere in the world, day or night.

The APM4AM-SAT has a total of six inputs. Channels 1-4 can be analog or digital, Channel 5 can be digital or an accumulator, and Channel 6 can be digital or an accumulator reset.

It is powered by a lead acid battery charged by a solar panel or AC charger. For corrosion applications, it can be used with rectifier interfaces, test point filters, and surge protection.UL/CUL approval is pending for installation in hazardous locations.

Source: American Innovations, 12112 Technology, Suite 100, Austin, TX 78727.

Touch screen monitor available for plant systems

The I/A Series automation system now comes with new flat-screen liquid crystal display monitor options.

This includes a new touch screen option for the high-performance 20 in. LCD monitor that combines features of LCD technology with the intuitiveness of touch screen operator interaction.

The firm says LCD displays have been shown to improve visual work performance, eliminate distortion and flicker, and reduce glare and associated eye strain to help increase operator productivity and well-being.

LCD displays also take up a smaller footprint in control rooms and use as much as 60% less power, the firm notes. LCD monitors do not emit electromagnetic interference.

The company is moving toward an all-LCD monitor offering for the I/A Series system.

Source: Foxboro Automation Systems, c/o Invensys Process Systems, 33 Commercial St., Foxboro, MA 02035.

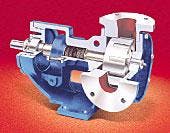

New oil field service pump

Here's the LV3900, a new oil field service pump with design enhancements intended to eliminate common causes of catastrophic failure.

The heavy-duty internal gear pump allows shaft packing to be replaced easily in the field without removing the pump from service.

The new pump offers greater strength, heavy load capacity, and more built-in protection than previous service pumps from this firm.

The LV3900 eliminates catastrophic failures via a disk that holds lubrication longer in a critical wear area of the pump.

Thrust control and adjustable rotor clearances compensate for wear and viscosity. Improvements include a larger shaft, thrust bearing, and bushing.

Source: Viking Pump Inc., 406 State St., Cedar Falls, IA 50613-0008.