Program advances oil recovery technology in Brazil

Petroleo Brasileiro SA (Petrobras) has successfully tested different technologies for improving oil recovery from its oil fields in Brazil.

Its program, known by its Portuguese acronym "PRAVAP" (Programa de Recuperação Avançada de Petróleo), entailed seven projects that spanned 5 years, involved 371,000 internal man-hours, and included service contracts with 31 organizations and individuals.

The program produced 374 technical publications on a diversity of scientific and technical subjects, and it played a decisive role in the economic feasibility of several exploration and production projects.

Technologies investigated involved:

- Improving waterflood efficiency.

- Applying advanced reservoir characterization techniques.

- Controlling water production.

- Recovering heavy oil.

- Preventing reservoir paraffin precipitation.

- Preventing reservoir asphaltene precipitation.

- Recovering oil from low-permeability carbonate reservoirs.

The success with these projects has convinced Petrobras to add new projects to the program's portfolio.

PRAVAP

To pursue its goal of increasing domestic oil and gas reserves and production set by its 1992-2001 strategic plan, Petrobras launched PRAVAP, an improved oil recovery research and development program to address major technological challenges facing oil recovery in Brazil.

About $26 million were spent between 1993 and 1998 on the seven projects previously listed. The projects were selected based on their significance in terms of the target oil recovery and their priority in the exploration and production portfolio. Project plans were focused on a particular field or fields, and the results from this work were shared with other similar fields within Petrobras.

To work on these projects, Petrobras gathered a multidisciplinary team of professionals from its research and development, headquarters, and operational units. This group interacted with universities, research institutes, service companies, and consultants (Table 1-see end of article).

Waterflood efficiency

Waterflooding is the dominant recovery method in Brazil. The fields being flooded initially held about 1,850 million cu m (11,600 million bbl) of original oil in place (OOIP).

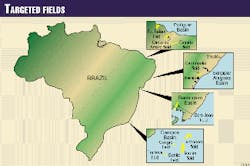

The Carmópolis field in Sergipe-Alagoas basin (Fig. 1) is the country's largest onshore oil accumulation, with about 266 million cu m OOIP. Discovered in 1963, it was quickly put on primary production.

In 1971, waterflooding started in the central portion of the field. Over the following 7 years, oil production increased to 800 cu m/d (5,000 b/d) because of infill drilling and increased water injection. But the combination of adverse fluid mobility ratio, reservoir heterogeneity, and lack of proper selective injection, led to a quick production decline.

A major program of stimulation and selective injection-production was implemented. This program stabilized production at a 600 cu m/day level through the mid-1980s. Waterflooding was then extended to the entire main block of the field, and the well pattern was changed from a five to nine spot, with a corresponding reduction in well spacing and injection rates.

Although this expansion proved successful in maintaining production at acceptable levels, production began to decline by the end of 1993.

This history qualified Carmópolis as Project No. 1 in the PRAVAP portfolio. The project scope included a review of waterflooding operations through improved reservoir characterization and flow simulation, as well as the investigation of other improved oil recovery methods that might reverse the declining production.

Besides an extensive effort in reservoir characterization and simulation, other major achievements of the project were the development of user-friendly software for production forecasting, interference test interpretation, and polymer-flooding simulation.

Technology implemented in the field included radioactive tracers for dynamic reservoir characterization and a polymer-flood pilot project, currently being monitored and evaluated.

The direct economic impact of this project on the local operational unit is indicated by a 4% increase in the projected recovery for the waterflooded area of the field and several approved projects with a total net present value (NPV) of $34 million.

Reservoir characterization

On a worldwide basis, the failure of several of the enhanced oil recovery field trials of the late 1970s and early 1980s can be attributed to a lack of proper reservoir characterization, which resulted in injected fluids not reaching the target oil. This was due not only to the eagerness to initiate field trials as soon as possible, but also to the state of the art of reservoir characterization at that time.

Since then, reservoir characterization has grown in importance for field development and recovery operations. New and better tools are now available.

Because most of Brazil's oil is in the deep offshore environment with its corresponding high exploration and development costs, Petrobras selected reservoir characterization as Project No. 2 for its PRAVAP program.

The project targeted the Namorado reservoir in the Albacora field, a turbidite deposit under development. Turbidite fields contain a considerable share of the oil in the offshore Campos basin.

The project's scope was to develop a package of integrated characterization tools covering the entire range of the reservoir variables and at the same time to contribute to the field's development.

From this work, the field's geological interpretation significantly changed (Fig. 2). The new geological model helped optimize the field's development plan based on fewer and more-efficient horizontal wells that increased estimated oil recovery by 7%, or 4.6 million cu m.

Water production control

Abnormal water production affects Brazil's oil fields that initially contained about 600 million cu m of OOIP. Water coning, poor sweep efficiency, and reservoir management problems were the major issues.

PRAVAP's Project No. 3 emphasized water coning and its treatment with profile modification, tailored for local reservoir conditions. The initial target was strong bottom aquifer drive, low salinity, light-oil reservoirs in the Potiguar basin.

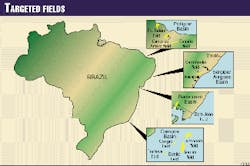

Research and development work focused on two polymer-based processes: a cationic type with wettability reversal characteristics and the anionic, polyacrylamid based with crosslinking characteristics. The highlight of the project was the development of the "Selepol" process.

The project also involved developing polymers resistant to both high temperature and salinity for other prospective reservoirs, as well as testing of mechanical means for preventing water coning. Mechanical methods included selective and simultaneous production from both the producing zone and aquifer.

The Selepol process combines the qualities of both cationic and anionic polymers to yield a highly selective affinity towards the water channels. It has outstanding control capabilities for in-depth reach around the well bore. Fig. 3 illustrates the results from one Selepol production profile modification.

The overall impact of this process, currently patent pending, can be measured by the almost 100 wells treated, and $10 million of net revenue anticipated from the additional oil production.

Heavy oil recovery

The Potiguar basin also contains about 300 million cu m of heavy oil (13-16° API gravity and viscosity greater than 1,000 cp) that is in relatively shallow reservoirs (280-350 m or 920-1,150 ft).

Discovered in the late 1970s, these accumulations were immediately put into production with cyclic steam injection. The results were acceptable; however, upon conversion to continuous steam injection, the project proved uneconomical because of poor production response. As a result, continuous injection was suspended and only cyclic steaming continued in selected areas of the field.

This was the scenario when this area was proposed for Project No. 4 of PRAVAP.

The project scope was to review the entire steam injection operation by means of reservoir characterization and determine the benefits of horizontal wells, infill drilling, optimized injection rates, and other heavy oil recovery methods besides steam.

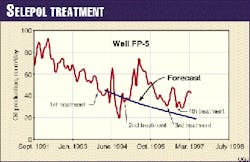

The project included a detailed characterization of the major producing formation (Açu), the drilling of shallow and short-radius horizontal wells in unconsolidated sand, and the implementation of two steamflood field pilots in the Fazenda Belém and Estreito fields.

The good performances of these pilots (Fig. 4) prompted the operational unit to launch feasibility studies for implementing heavy oil steamfloods on a commercial scale. To improve the economics, these studies are considering the construction of a gas-fired power plant to take advantage of co-generation for reducing the cost of steam.

Because of this work, a recovery of 15 million cu m of additional reserves is forecast to be produced from the Estreito and Alto do Rodrigues fields.

Reservoir paraffin precipitation

In the Reconcavo basin, some of the reservoirs, containing an initial 400 million cu m of OOIP, exhibit a surprisingly poor recovery. These reservoirs contain a commercially highly valuable waxy crude with a high API gravity and have fair reservoir characteristics.

For many years, the poor recovery was treated in a conventional way. Three major reservoir studies led to several upgrades of the ongoing waterflood operations, with limited success. Then in the late 1980s, the field's notorious paraffin deposition problems in tubing and flowlines were associated with the overlap of the crude's cloud-point range and the reservoir temperature.

This led to the hypothesis that the crude might be in a two-phase (solid-liquid) state in the reservoir, thus explaining the inefficiency of waterflooding.

The scope of PRAVAP's Project No. 5 was to test this hypothesis and propose alternatives to waterflooding.

The validation of the reservoir paraffin precipitation assumption included:

- Collecting direct evidence for the phenomenon.

- Justifying the assumption from the standpoint of the basin's geology.

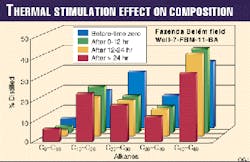

Fig. 5 shows the produced oil's composition during thermal stimulation of a well in the Fazenda Bálsamo field. The figure makes clear that thermal treatment did remove long-chain alkanes, and this evidence supports the assumption that paraffin precipitation occurred in the reservoir.

In regard to geology, two major tectonic uplifts in the basin at 1,500 and 750 m were identified by analyzing fission tracks in the apatite minerals of the producing Sergi formation. These were dated before the hydrocarbon migration or accumulation.

The estimated 30° C. (86° F.) drop in reservoir temperature associated with these uplifts cross validates the paraffin precipitation assumption. It suggests that the oil in place is at an equilibrium cloud-point temperature condition, with solid wax deposits co-existing with a liquid oil phase.

Based on this, steamflooding appeared to be one way for improving oil recovery.

The Dom Joao field was selected for a pilot test. The field initially had 113 million cu m of OOIP and had been producing for more than 50 years, but its estimated oil recovery factor was only 15%.

The pilot started in mid-1997 and is still far from complete. But estimates to date indicate that the oil recovery factor will increase by 12%, although economic feasibility is dependent on a minimum $19/bbl oil price. If steamflood operations are expanded on a commercial scale, the estimate is that about 200,000 cu m of oil will be recovered.

Asphaltene precipitation

In the early 1990s, at the start of the development of Marlim field in the Campos basin, the field was included in the PRAVAP program because:

- Some wells had productivity problems.

- The crude contained an average 0.5% asphaltene.

- This giant field was very important to meet Brazil's future oil demand.

This project, PRAVAP Project No. 6, aimed to study asphaltene phase equilibrium under reservoir conditions and determine preventive and remediation procedures, if necessary.

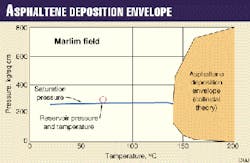

After an extensive thermodynamic investigation, both theoretical and experimental, the asphaltenes in Marlim crude were found to be very stable relative to an eventual reservoir pressure depletion (Fig. 6).

This conclusion has been confirmed through almost a decade of asphaltene trouble-free production from this field.

Low-permeability carbonates

The Enchova and Bonito fields, the first fields discovered in the Campos basin in the early 1970s, initially held about 400 million cu m OOIP in tight (0.1-25 md) carbonates of the Macaé formation.

Despite satisfactory initial flow rates, the wells typically had an accelerated productivity decline followed by a stabilized production rate. Therefore, these reservoirs were developed to a limited extent and even in the areas fully developed, recovery to date has reached only 5% of OOIP. Estimated ultimate recovery is 15% of OOIP.

These reservoirs were selected for PRAVAP Project No. 7 because of:

- Large amount of OOIP.

- Low recovery to date.

- Possibility of not attaining the projected ultimate recovery within the life of the offshore installations.

The scope of Project No. 7 was to determine a redevelopment plan for the two fields by thoroughly characterizing the low-permeability carbonate reservoirs of the Macaé formation through rock mechanics analysis and fracture mapping.

Redevelopment, most likely, would include well stimulation together with drilling horizontal and multilateral wells.

But because of the 1997 enactment of the law that opened the Brazilian oil sector to private enterprise, Petrobras decided to concentrate its investment in the giant fields of Albacora, Marlim, and Roncador. As a result, Project No. 7 was put on hold.

Consequently, few parts of the project were implemented. A successful horizontal well was drilled in the Enchova field and a well with two laterals was drilled in the Bonito field.

The major impact of this project, however, came from applying the concepts developed for the Bonito field to the development of the recently discovered Congro field, in the same basin (Fig. 1).

The scarcity of actual reservoir data for the Congro field and the press to meet the deadline for presenting a development plan to Brazil's National Petroleum Agency led Petrobras to decide to use the reservoir characterization developed for the Bonito and Enchova fields in the economic feasibility study for the Congro field, located in a similar geological environment.

References

- Luvizotto, J.M., Subprogram 03301-Efficiency of Waterflooding, Petrobras Internal Report (in Portuguese), E&P-SEAL/Geret/Gerev-1, Aracaju, SE, Brazil, December 1998.

- Barroso, A.S.(Editor), Advanced Reservoir Characterization, Petrobras special publication (in Portuguese), E&P/Gerer/Gecar, Rio de Janeiro, July 1996.

- Lima, J.C., et al., Water Production Control Project Fazenda Pocinho/Palmeira Field (in Portuguese), Final Report-Petrobras, E&P/RNCE, Aracaju, SE, April 1995.

- do Vale, J.E.F.R., Reservoir Study-Steamflooding Pilot Project-Fazenda Belém Field-Potiguar Basin (in Portuguese), Petrobras Internal Report-E&P RNCE/Geret/Gecar, Aracaju, SE, May 1996.

- Khalil, C.N., and Rocha, N., Detection of Formation Damage due to Paraffin Precipitation at Reconcavo Basin (in Portuguese), Petrobras Internal Report, Cenpes/Diplot/Setraf 26/95, December 1995.

- Leontaritis, K.J., Estrela do Mar Reservoir Oil Asphaltene Phase Bahavior Modeling with the Thermodynamic-Colloidal Model, Technical Report, April 1997.

- Oliveira, R.M., Blauth, M., and Spadini,A.R., Quality Mapping of the Quissama Reservoir in Bonito Field (in Portuguese), Petrobras Internal Report, Rio de Janeiro, RJ, June 1996.

Technical service providers (Table 1)

Organizations

- Federal University of Rio de Janeiro

- State University of Campinas

- Catholic University of Rio de Janeiro

- University of Liverpool

- Heriot-Watt University

- Institut Français du Petrole

- Brazilian Center for the Development of Nuclear Energy

- Petroleum Recovery Institute

- Intera Consultants Ltd.

- Asphwax Inc.

- Nalco/Exxon Energy Chemicals Brasil

- Geotrack International Pty. Ltd.

- Schlumberger Serviços de Petróle Ltda.

- Core Laboratories Inc.

- Reservoir Laboratories A.S.

- Consub Equipamentos e Serviços Ltda.

- Oilphase

- Beicip-Franlab

- Institutt for Energiteknikk

- Norsar

Consultants

- Gholam Ali Mansoori

- Clayton V. Deutsch

- Roger Anderson

- Dan Marchesin

- Roy M. Knnap

- Rae Mohan Srivastava

- Pavel Bedrikovetsky

- Larry W. Lake

- Syed M. Farouq Ali

- John W.F. Costerton

The Author

Roberto F. Mezzomo is currently manager of the Petrobras strategic program in improved oil recovery. He has more than 20 years' experience in research and development for exploration and production activities at the Petrobras R&D Center in Rio de Janeiro.

Mezzomo has a BS in chemical engineering from the Federal University of Rio Grande do Sul, Brazil, and an MS and PhD in chemical engineering from Clarkson University, N.Y.