Record exchanger installed in Saudi Arabian olefins project

One of the largest heat exchangers of its type has been installed for Arabian Petrochemical Co., Petrokemya, by Altec International LP (now Chart Heat Exchangers), La Crosse, Wis.

The contract was for brazed aluminum heat exchangers and related assemblies for Arabian Petrochemical's new Olefins-III plant in Al-Jubail, Saudi Arabia.

null

Altec provided 14 brazed aluminum heat exchanger assemblies in various sizes. The exchangers have brazed aluminum, plate-fin heat exchanger in place of usual tube bundles. Altec says the fins of a brazed aluminum exchanger provide greater heat-transfer surface area density and facilitate tighter temperature approaches than regular shell-and-tube exchangers.

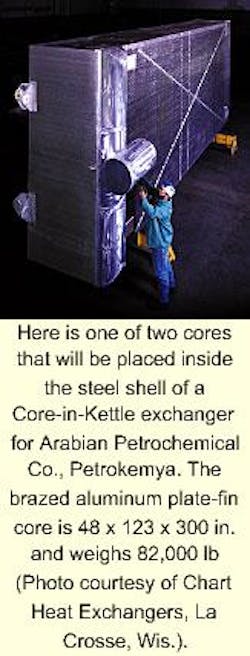

Each basic brazed aluminum heat exchanger is also called a core. A Core-in-Kettle exchanger is one or more cores packaged inside a steel shell.

"Core-in-Kettle"

The assemblies included several Core-in-Kettle exchangers, a cold box, and several brazed aluminum heat exchangers.

One of these Core-in-Kettle exchangers was the largest that Altec had ever built. It has two cores installed inside a single shell. Both the core and the vessel sizes were the largest that Altec had ever used for this type of heat exchanger.

The steel vessel that held the two largest cores was 58 ft, 10 in. long with a 140 in. OD. Total operating weight of this Core-in-Kettle was 432,000 lb.

All Altec items were shipped in summer 1999. The new plant, expected to start up in 2000, will be capable of producing 800,000 tonnes/year of ethylene.