Shear-sensitive fluid cures Canadian lost circulation

A single-stage, shear-sensitive plugging fluid (SSPF) treatment, which allowed Canadian operators to cure lost circulation zones in 10 wells, provided distinct operational and economic advantages over conventional reactive and temperature-activated methods.

In 1997, Statoil AS developed a lost-circulation fluid that can be pumped through the existing bottomhole assembly without losing rig time associated with tripping and mixing lost circulation material (LCM).

A high-pressure drop, experienced as the fluid passes through the drill bit, activates the fluid within 30 sec to 1 hr, which in turn initiates the gelling process. Once the fluid gels, it produces a solid barrier between the thief zone and wellbore.

Composition

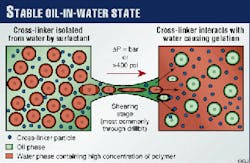

The fluid originates as a shear-sensitive, invert emulsion (water-in-oil). In its initial state, the oil phase encapsulates a cross-linker while the water phase encapsulates a polymer. This water-in-oil invert emulsion is maintained by a low concentration of lipophilic surfactant, or emulsifier (Fig. 1).

Although the water droplets are larger, the surfactant produces a well-developed curvature around the water droplets; therefore, only very small amounts of the cross-linker can cross the interfacial membrane into the water phase.

By shearing the SSPF through the drill-bit nozzle, the process produces a pressure drop that is greater than 400 psi, triggering a rupture in the interfacial membrane. This causes the emulsion to flip to a more stable oil-in-water state as shown in Fig. 1.

At this point, the cross-linker is released into the continuous phase of the water, initiating a reaction that creates a highly viscous gel structure once the fluid enters the lost-circulation zone. The gel setting time can be controlled from a few seconds to 1 hr by adjusting the emulsifier concentration, making the emulsion more or less shear sensitive (Fig. 2).

Conditions of application

Prior to commercialization, the SSPF lost-circulation technology, licensed to and further developed by Schlumberger, had treated more than 40 field applications in areas prone to heavy mud losses such as Canada, the Middle East, Far East, North Sea, and Africa.

It is well-suited to most worldwide drilling locations that require lost-circulation control, with the exception of wells where bottomhole temperatures exceed 190° F. Fortunately, tests have identified several methods, including the addition of cement, that may even increase this temperature range.

The inclusion of cement may additionally add compressive strength, increase the extrusive resistance of the set gel, and improve the durability of the treatment prior to cementing off the lost-circulation zones.

Comparing technologies

The SSPF lost-circulation treatment provides operational advantages over reactive and temperature-activated pills. First, the SSPF (Instanseal) treatment is stable enough to pump through any bottomhole assembly while operators can still easily pull downhole tools and coiled tubing once it sets up.

Additionally, the SPPF treatment, which is compatible with all mud types and weighting agents, can be prepared weeks in advance without deterioration.

Reactive pills, on the other hand, cure lost-circulation problems by simultaneously pumping one fluid down the drillstring and another through the annulus, both at high rates.

If performed correctly, the point of contact between the drillstring and annular fluids occurs near the lost-circulation zone. As the fluids mingle, a viscous and rubbery solid mass quickly forms.

Usually referred to as "gunk," the mass is then squeezed into the loss-circulation zone. This procedure, in many cases inaccurately placed, can result in poor penetration of the sealing fluid into the fractured formation or voids.

With temperature-activated pills, gel time depends on bottomhole temperature, cross-link concentration, and mixing time. The accuracy of these variables determines whether the fluid, which is mixed at the surface, successfully penetrates the formation before cross-linking into a gel.

One obvious drawback to this approach occurs in situations of total fluid loss when there is no time to record temperature measurements. Thus, bottomhole temperature must be estimated, leading to potential errors such as over-retardation, pill contamination, or premature setting.

If the operator miscalculates the temperature variable, time can be lost waiting for the gel to set. Additionally, the gel may set up in and around the bottomhole assembly, causing operational problems.

Proper execution

The SSPF treatment is originally cement and solids free, with a rheology similar to the drilling fluid. It contains about 80% water and 20% oil, with the polymer, cross-linker, and emulsifier interspersed as described above.

By adjusting the emulsifier concentration, the SSPF can be made more-or-less sensitive to shear. For example, a large diameter, openhole section in a soft formation may require a drill bit with as many as five large nozzles.

To achieve a pressure drop of 400 psi or more in this case, the flow rate must be increased by temporarily plugging select nozzles with biodegradable balls. But because these balls require hours to degrade, a simpler solution can be provided by lowering the emulsifier content and adjusting the SSPF's shear sensitivity to 300 psi (Fig. 2).

A portable shearing tester accompanies the SSPF technology, aiding in the shear adjustment. This tool provides a quick and accurate means of determining the on site setting time derived from various pressure drops. For example, high-pressure drops result in shorter setting times and low-pressure drops conversely result in longer setting times (Fig. 2).

The shearing tester is just one of the quality-control measures provided at the wellsite to ensure optimal application of the SSPF fluid. The operator plays an integral roll in its successful execution, as well, by ensuring that good drilling practices are in use.

For example, lost-circulation problems should be treated as soon as they occur. Additionally, drilling ahead without returns (blind) should be avoided as this can lead to the fracturing of multiple zones at unpredictable depths while impacting subsequent formation evaluation efforts.

Like other techniques used to cure mud losses, the SSPF fluid is most effective when placed across short intervals of 20-30 ft. After placement of the pill, the drill bit is either held static with rotary slips, or it can be raised above the lost-circulation zone. In either case, the driller shuts down all pumps to allow the gel to set.

While setting time can be as little as a few seconds, 5 min is ideal. The gel should remain fluid long enough after passing through the bit effectively to penetrate the formation and seal the loss zone. As this technology continues to be used, placement of a drill bit within, above, or below the lost-circulation zone will be continuously investigated to achieve good zonal coverage.

In a vertical well, density hierarchy is the most important criteria for effectively displacing a fluid with another fluid. To prevent any dilution of the SSPF during placement, weighting agents can be added to the emulsion to make it heavier than the displaced drilling fluid.

If the pill density matches the drilling fluid density, then the drilling fluid is lifted so the pill is not contaminated, resulting in an undiluted pill in the loss zone. The high yield point of the emulsion before or after shearing-typically 70 lbm/100 sq ft-further ensures effective displacement of the previous fluids and no contamination, resulting in a high-quality gel.

Canadian case studies

Before the SSPF fluid solution, Beau Canada Exploration Ltd. drilled five wells in the Chinchaga field in northwest Alberta.

Each well encountered lost-circulation problems in the upper portion of the Debolt formation, an interval consisting of permeable limestones and interbedded porous dolomites. Treatment required more than one attempt to fix the zone with LCM, at a loss of several hours to days of drilling time. Two of the wells even required setting cement plugs.

Beau Canada, taking advice from a toolpusher with prior experience, tried the SSPF treatment on its next well. As expected, the drilling operation encountered lost circulation at 1,182 m and the operator decided to continue drilling blind. When a second lost-circulation zone was encountered at 1,191 m, however, the drillstring became stuck at 1,205 m.

The drilling crews subsequently recovered several stuck drill collars. And because gas was known to be present in the well, there were concerns about losing circulation again once the remaining collars and bit were recovered, possibly producing a difficult situation of tripping out with no means to circulate.

Consequently, Beau Canada decided to cement the remainder of the fish at 944 m and sidetrack the well. In the new hole section, Beau Canada encountered total losses at 1,186 m. This time, the drilling crew immediately mixed and pumped a 37.5 bbl SSPF pill and, after waiting 45 min, filled the annulus with mud. After observing no fall back, the company re-established circulation.

Drilling continued onward until 1,189 m when total losses were again encountered at 1,190 m. The operator drilled blind to 1,197 m then pumped another 37.5 bbl SSPF pill. After waiting 1 hr to be absolutely certain the gel had set, Beau Canada began drilling ahead with no additional problems.

Amoco Canada

Amoco Canada Petroleum Co.'s Cranberry 10-19 well, drilled in early 1999 at Slave Point, northwest Alberta, also encountered lost-circulation problems while drilling through the Debolt formation.

When the drilling crew encountered total losses at 860 m, it pumped LCM pills and then drilled ahead to 873 m with partial returns. Another LCM pill was pumped at 873 m followed by a third pill at 918 m. The operator drilled ahead with partial returns to 949 m and then unsuccessfully pumped LCM pills in an attempt to cure the losses.

At this point, the operator pumped a 77-bbl SSPF pill, leading to surface returns shortly thereafter. The hole began losing circulation, however, and the crew pumped a second 37.5 bbl SSPF pill, reestablishing total circulation after 16 bbl. Drilling resumed without lost circulation to TD, and the hole was cased without incident.

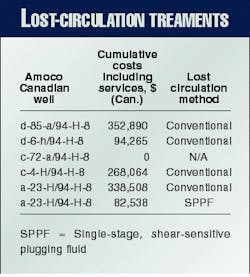

The Cranberry 10-19 became the first Slave Point well Amoco drilled in the immediate area without applying multiple cement plugs to cure Debolt losses. In total, the SSPF plugs used on the Cranberry 10-19 saved about $16,000 (Can.) in 1999 dollars compared with the Cranberry 8-24 well drilled in 1990 (Table 1).

The treatment of lost-circulation problems on the Cranberry 10-19 resulted in only 12 hr of rig downtime at an expense of $36,000 (Can.), as compared with 2 days and $52,000 (Can.) for the Cranberry 8-24.

Amoco Canada believes additional costs could have been saved if the SSPF treatment had been immediately used up hole at 949 m in the Cranberry 10-19 rather than trying to cure losses with LCM.

Acknowledgment

The authors wish to thank Beau Canada and Amoco Canada for permission to publish the case studies. Additionally, they thank Kamal Arsanious, David Bexte, and David Quinn for their contributions to this article.

The Authors

Gregg Lindstrom is a drilling superintendent for Beau Canada Exploration Ltd. in Calgary. He previously worked as a wireline engineer for Western Atlas.

Al Nord is a senior production specialist for BP Amoco in Calgary. His work focuses on drilling engineering projects, primarily in horizontal well drilling for heavy oil properties in northeast Alberta.

Les Johnson is a field services manager for Schlumberger, Grande Prairie, Alta.

Patrick Murphy is a field engineer for Schlumberger, Grande Prairie, Alta.

Philippe Revil is product champion for the InstanSeal and UniSlurry lines for Schlumberger in Houston.