Unocal Thailand slashes well planning cycle time

Jay E. Valusek

LifeLines Consulting

Houston

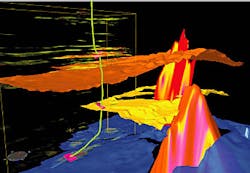

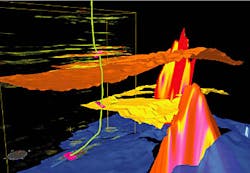

Integrated seismic and well planning (Fig. 1).

- UNOCAL'S GULF OF THAILAND GAS FIELDS [169,872 bytes]

- Prior to adopting integrated technology, Unocal geoscientists had to manually plot potential well paths on seismic sections and maps-a very time-consuming process (Fig. 3). [22,303 bytes]

- Interactive fault section with wellbores (Fig. 4). [84,527 bytes]

- Amplitude clouds (Fig. 5). [30,022 bytes]

Unocal Thailand Ltd. has successfully reduced cycle times by integrating seismic interpretation and well-path design throughout the well-planning stage and drilling operation.

Over three decades ago, Unocal was the first foreign energy company to win petroleum exploration rights in the Kingdom of Thailand. In 1973, Unocal Corp. discovered the first commercial natural gas field in the Gulf of Thailand. Production began in 1981. At that time, the Kingdom imported 95% of its commercial energy.

Today, Unocal produces about 1 bcfd of natural gas, which supports 35% of Thailand's electricity generation and 20% of its total energy supply. The company has drilled about 1,200 wells and produced more than 3 tcf of gas.

Natural gas provides a cheap domestic source of energy, reducing Thailand's dependence on foreign crude. But demand is rising. Currently, Thailand consumes about 1.5 bcfd. That rate could double by the year 2005. To help meet the nation's growing energy needs, Unocal Thailand plans to increase its daily gas production at least 30% over the next 3 years.

The company has signed four gas sales agreements with the Petroleum Authority of Thailand (PTT). To meet ambitious production targets, Unocal Thailand must drill a large number of wells as rapidly, economically, and accurately as possible.

New integrated 3D seismic visualization and well planning technology from Landmark Graphics Corp. is helping the company achieve its strategic goals (Fig. 1). This software helped Unocal Thailand to reduce gas well-planning cycle time by 50 to 75% in the Gulf of Thailand (Fig. 1).

Pailin field development

Historically, Unocal Thailand has averaged about 55 wells/year. However, in recent years the pace of drilling has accelerated dramatically. Innovative slimhole technologies have made drilling faster and more efficient than ever. In the early 1980s, for example, a typical gas well about 11,000-ft deep cost the company over $5 million and 68 days to drill. Today, Unocal spends about $800,000 to drill the same well in less than 6 days.During 1998, about 150 wells were drilled in the Gulf of Thailand. Sixty of those were primary development wells in the Pailin field on the west flank of the Pattani basin, near the geographic center of the Gulf (Fig. 2). As operator, Unocal planned to install five 12-well platforms in 1998, and five more in the year 2000.

Pailin is currently the company's largest single project in terms of infrastructure. Production is covered under a 30-year gas sales agreement signed in 1996. Eventually, about 30 wellhead platforms and at least 1 central processing platform will be installed in the field.

A 50-km subsea pipeline from Pailin to PTT's Gulf of Thailand trunk lines will be completed in 1999. The field is expected to begin production at about 165 MMcfd, rising to 330 MMcfd by 2001.

Technical challenges

Three geophysicists are working on the Pailin asset, two from Unocal Thailand and secondee (outside professional) from Pttep, the major equity holder. Lance Brunsvold, senior geophysicist, says, "The main problems we're up against here are small reservoirs and high temperatures."Gas fields in the Pattani Trough, a rifted basin, occur along north-south trending, intensely faulted structures in fluvial-deltaic sediments. Due to complex faulting and stratigraphy, individual reservoir compartments are very small. Because reservoirs deplete rapidly, many wells are necessary.

Thin gas sands tend to stack up behind normal faults throughout a 3,500-ft section extending down to about 11,000 ft subsea. To be economical, individual wells must penetrate multiple pay zones along the upthrown side of a fault. The closer to the fault surface they can get, the better. Wells are typically drilled between 200 and 500 ft from the fault, the exact location of which is determined from 3D seismic.

However, severe pressures and bottom hole temperatures near 400° F. impose strict limitations on directional well bore design. To avoid burning up expensive downhole equipment, well paths must build and turn above 6,000 ft subsea, then penetrate gas zones at a constant angle just behind the sealing fault. Fast, careful well planning, therefore, is critical to success.

Historic well planning

Years ago, Unocal geoscientists, using 3D seismic interpretation software, would map target reservoirs, pick x,y,z locations, and hand them over to the drilling department. Drilling engineers would take them to a directional drilling contractor, plan a well bore, and determine how much it would cost.These locations were often found to be uneconomical to drill, given local drilling constraints. Geoscientists then had to review their maps, change target locations, and send the targets back to drilling, again and again.

"Each iteration could take several days," says Brunsvold. "I've heard the entire well planning process could take 3 weeks to a month." Well planning ate up a considerable amount of each professional's time-time that would have been better spent refining the subsurface interpretation.

To speed up the process, geoscientists needed to know-before handing off targets to drilling-if there was at least one well bore that could penetrate all the desired targets while still meeting the basic drilling constraints.

In the early 1990s, geophysicists with Unocal Thailand wrote several custom applications. One tool created seismic sections closely paralleling a fault plane-called "fault sections"-to enable geophysicists to target amplitude anomalies at various distances from the fault.

Another enabled them to view interpolated seismic data along the plane of a potential well bore-called a "well section." A third program did basic well planning-enough to verify that an economically viable well could be drilled, before consulting with the drilling department. Once they were satisfied, geoscientists passed their targets to the drilling department to optimize the final well path.

These tools successfully reduced cycle time from weeks to days. "With this system," says Brunsvold, "the whole process of targeting and planning a single well would take three or four days."

Despite an order of magnitude improvement in planning time, there were drawbacks to Unocal's custom applications. "The system was not interactive. We had to plan all of our wells on paper," says Brunsvold.

"Custom displays were strictly black-and-white hardcopy. Fault sections and well sections could take hours to run, depending on size. So we usually generated them at the end of the interpretation process.

"To plan a well bore, we spent a lot of time essentially drafting. We'd identify two potential target points by x,y,z and let the program calculate a series of possible well courses. Then we would select one that seemed to fit our drilling criteria, plot that on paper, and manually overlay it on our fault sections and amplitude maps to see if we hit all of our anomalies (Fig. 3). It took a huge amount of time and paper. We couldn't look at many different options."

Furthermore, regardless of the true strike of a particular fault, Unocal's custom software projected seismic fault sections into a north-south plane. For faults with significant deviation from N-S (North-South), this technique would bend common depth point CDP lines across the section and crowd seismic line numbers on the hardcopy display.

"It was not uncommon," Brunsvold observes, "to plan a well and find out it was in the wrong position when you projected it on a map."

Over time, as drilling activity accelerated, Unocal Thailand began looking for a more interactive, more tightly integrated approach. "The goal was to put tools in place that would enable us to increase the number of wells we could drill each year, without increasing people," says Brunsvold. "To do that, we needed to further reduce the cycle time that an average geoscientist spent on planning wells."

Integrated well planning

In June of 1996, the company kicked off a project to develop an integrated computing system that would incorporate the functionality already used in well planning. Geophysicists, geologists, and engineers worked together to define system requirements, and they put out a "Request For Proposal" by September 1996.In early 1997, the company took a close look at Landmark's next-generation UNIX well bore planning and 3D seismic interpretation applications, which were tightly integrated via the company's common project data management system. The new 3D visualization software already came with a flexible fault-section display that enabled users to move through the 3D seismic volume parallel to any geological surface (Fig. 4).

"It was exactly what we needed," says Brunsvold. "We were no longer restricted to projecting onto a north-south plane. Now we could rotate the section to match the strike of a fault, which gave us a more accurate view of all the seismic amplitudes that our wells could penetrate." What's more, it projected the section instantaneously, onscreen, and in color.

Brunsvold and two colleagues, Kamal Sandarusi and Martin Sharps, beta tested the well bore planning software and worked with Landmark to develop additional functionality in the new 3D seismic technology.

During 1997, they systematically refined the integrated seismic interpretation and well planning work flows. "We decided to invest the time to provide feedback to the developers, so the system would work superbly before we rolled it out to other geophysicists," says Brunsvold. "It was a joint effort. Landmark responded to a lot of our requests, and came out with some excellent tools."

The UNIX well-bore planner enables geoscientists to plan and visualize 3D well paths directly in the 3D seismic volume. "They're very tightly integrated," Brunsvold notes. "You pick amplitude targets in time in the 3D earth cube, and based on your velocity function, the well-bore planner converts them to depth and assigns a well-bore geometry. If you grab a target in one application, you can watch it move interactively in the other. That's the real power of the system."

UNIX well-bore planning is also linked with Compass, a full Windows-based directional well-planning application used by many drilling engineers in the industry. "I use the PC application to generate final plans on more-complex wells with multiple dogleg severities," says Brunsvold. "Then everything I send to the engineers comes out of that application."

In addition, he uses the PC tool to monitor drilling progress on a daily basis. By bringing a projected well path into the integrated well-planning system, he can view it in any seismic application and see where it will penetrate a particular amplitude anomaly.

"Most wells naturally tend to drop angle deeper in the section," he says. "In one case, I did a projection and asked the drilling department to maintain the current inclination until we went through the target. We hit the sweet spot dead center."

Brunsvold used this new system to optimize existing well plans for the Pailin A platform and to plan wells for the Pailin D in the Gulf of Thailand. Colleagues have used it to plan two other platforms in the Pailin field, as well as a horizontal well in the Trat field, and an infill project in the Kaphong field.

Drilling at Pailin commenced in March 1998, and was to have been completed by year end. At about that time, Unocal Thailand planned to roll out the integrated 3D visualization environment to the rest of the geophysicists on staff. Unocal geologists will now begin migrating from paper-based to digital work flows as well.

Integration benefits

"Planning the actual well bore takes an insignificant portion of our time with this new technology," Brunsvold explains. "That leaves more time to focus on doing a better interpretation. I don't think anyone realized how much time we would save."According to Brunsvold, it took geoscientists an average of 6-8 months using the old system to complete a subsurface interpretation, map amplitudes, and prepare well plans for a typical 12-well platform. An estimated 25% of that time-6 to 8 weeks-was spent doing detailed well targeting. Each well plan required about 3-4 days. With the new system, well planning time has been slashed 50-75%.

"On the Pailin D platform, I cut down the overall interpretation process to about 8 weeks, and spent less than 3 weeks targeting 17 wells," says Brunsvold. "But it's hard to make a direct comparison, because that time was spent optimizing wells, not just planning them. We relied on various 3D views to provide amplitude information we used to get only from extensive horizon picking (Fig. 5). Only a few key events were picked strictly for amplitudes. That saved a lot of time."

With the new tools, Unocal geophysicists no longer have to wait until the end of their interpretation to generate vital fault and well-section displays. "We can incorporate them right up front, and use them as a quality-control and well-planning tool. You can move well bores onscreen, evaluate different options, hit all the anomalies you want, and determine the most cost-effective well placement. My gut feeling is, we've got to be drilling better wells with this system."

During drilling operations on the Pailin A platform last spring, for example, one well came in much better than expected, setting up an additional viable well location in the fault block.

"We had an empty slot available," says Brunsvold. "Within one day, I planned another well and got it to drilling without any slowdown to the program." At the same time, he was already planning wells for the Pailin D because the drilling schedule had been unexpectedly accelerated by 2 months. "With the old system, it's doubtful there would have been enough time to plan all the wells in such a short period of time."

By optimizing its interpretation and well-planning process with advanced technology, Unocal Thailand should be able to meet its aggressive gas production targets-and continue to support the growth of Thailand's economy at the turn of the new millennium.

Acknowledgments

The author wishes to thank Unocal Thailand Ltd. for permission to publish this case study.The Author

Jay E. Valusek is a geologist and writer specializing in information technology for petroleum exploration and production. Currently, he is also a contributing editor for Solutions, the global newsmagazine of Landmark Graphics Corp.For 9 years, Valusek was senior writer and corporate communications specialist for Landmark. Previously, he was employed as a reservoir development geologist with Pennzoil Co. in Houston. He graduated with honors from Wichita State University and earned an MS in geology from the Colorado School of Mines.

Copyright 1998 Oil & Gas Journal. All Rights Reserved.