Syntroleum unveils hydrate recovery process

Collecting and recovering methane hydrates-the ice-like solids formed by the entrapment of natural gas molecules in ice at very low temperatures-and doing so economically has long been a major challenge for the oil and gas industry.

Syntroleum Corp., Tulsa, was recently awarded a patent for its method of freeing, recovering, and converting to liquids gas from hydrates trapped on the sea floor. The comprehensive system, says Syntroleum, would "substantially eliminate or reduce" certain problems related to other hydrate recovery methods.

Vast quantities of methane hydrates are believed to exist. The US Geological Survey pegs worldwide natural gas resources from methane hydrates at 400 million tcf, vs. 5,100 tcf of natural gas reserves. The same survey estimates the total US gas hydrate resources at about 200,000 tcf vs. 1,400 tcf for conventional gas.

Methodology

Although Syntroleum's process is yet to be proven, the inventor maintains it would solve many of the problems associated with hydrate recovery, such as recovery and transport of the finished product.

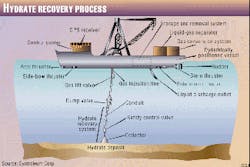

The process is exothermic; it creates heat in the form of steam that gasifies the trapped hydrates. The system is coupled with a vessel that would transport the liquefied gas to market. The vessel's subsystems include:

- A positioning system for holding the vessel in location over a hydrate formation.

- A hydrate-recovery system, linked to the vessel, that delivers hydrates from the sea floor to the vessel and gasifies and recovers the trapped gas.

- A gas liquefaction system.

- A storage and removal system.

The hydrate-recovery system, says Syntroleum, would include a device for recovering hydrates from the sea floor and a main conduit for transporting them to the surface vessel. It might also include a conduit through which gas would flow from the hydrates and another through which liquids would be delivered onto the hydrates.

The hydrate collection device would contain one or more of the following: a system for creating an electric current across the hydrates, numerous heating elements, and an agitator for stirring the hydrates. And the gas-conversion system would include: a unit for producing a synthesis gas; another, joined to the syngas unit, for converting the gas to liquid hydrocarbons; and a turbine for compressing air, which would be transported to the synthesis gas unit. The compressed air also would provide energy to power the gas-conversion system and at least a portion of a hydrate-recovery subsystem, says Syntroleum.

Among the claimed technical advantages of the invention are the use of excess power from the conversion process to recover the hydrates from the sea floor efficiently and the rapid removal of the hydrates via power-enhanced recovery techniques.

"This patent is a unique addition to our intellectual property portfolio and has great potential to further expand Syntroleum's presence in the emerging synthetic fuels industry," said Mark A. Agee, Syntroleum president and CEO (see Watching the World, p. 33). "At the same time, we want to be the first to say that this technology, while extremely promising, remains un- proven. We will be working diligently to identify partners for bringing it to commercialization."

Syntroleum's patent approval comes at a time when numerous countries' governments-including the US, Japan, India, and Canada-are looking into enhanced methane hydrate recovery methods. The US House of Representatives science committee recently passed a bill that would provide $42 million over 5 years for the US Department of Energy to research the process (OGJ, May 3, 1999, Newsletter).

In November, an international consortium of 10 firms, led by Japan National Oil Corp., will attempt commercial exploitation of methane hydrates. Funding for the project has come from Japan's Ministry of International Trade and Industry.