HYDRAULIC FRACTURING—1: Natural fractures influence shear stimulation direction

Hydraulic fracturing in the presence of natural fractures causes a complex network of fractures to form because of shear and tensile failure.

During hydraulical fracturing, shear failure in a reservoir appears pervasive where natural fractures occur.

Hydraulic fracturing treatments induce a network of shear and tensile fractures in a reservoir and enhance the virgin permeability in a large volume around a well.

In the Barnett shale, for example, microseismic bursts, which are shear-induced, are numerous, and extensive. Systematic shear failure appears to occur over a large region. Other gas fields in North America display similar complex attributes.

There are four keys for understanding, modeling, and predicting shear stimulation and its benefits. Many studies have discussed each key separately; however, the studies generally have not integrated the four keys.

The role of natural fractures as related to these keys is the subject of this series of two articles. This first part will discuss the complex geometries formed and the first key, while the concluding part will cover the remaining three keys.

Complex geometry

The presence of natural fractures, or planes of weakness, causes a hydraulic fracture to have a complex geometry. Studies argued this more than 15 years ago, in the oil and gas context,1 and the subject again recently has gained emphasis.2

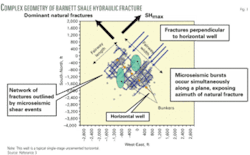

A complex fracture geometry results from both tensile and shear failure. In the Barnett shale, for example, observations show microseismic shear events are numerous, and one can connect some of the simultaneous bursts with straight lines extending for hundreds of feet.

The pattern of bursts extends out to large distances (Fig. 1).3

It is hard to discount systematic shear failure occurring over a large region.

The balance between tensile and shear failure, however, depends on many things, including natural fracture orientation with respect to the stress field (Fig. 2).4 5 In coals, the cleats inflate if aligned with the in situ stresses, but shear when the cleats are at about 45º to the in situ stresses.5 The same behavior occurs in hard rock.6

In coals, shear slippage at layer interfaces or intersection with existing cleats or natural fractures can disrupt elastic coupling and further create a complex fracture network.4

The shape of the induced fracture network also depends on injection conditions. A low-rate injection of nonviscous fluid, such as water, will tend to form a rounder fracture network. This is the situation in the Barnett shale, where the slick water jobs inject at rates of about 70 bbl/min into six or more segments of a long horizontal well (about 3,000- ft total length).

In contrast, a slug of viscous cross-linked gel pumped at high rate ahead of a foamed-water fracture can reduce the fracture complexity in coalbed methane wells.7

Studies have diagnosed a variety of network shapes by mining back coalbeds (Fig. 3)8 and after injecting paint with the hydraulic fracture fluid. The majority of such shapes, however, are elongated, and Fig. 3a is typical, as discussed previously.9

From the old-paradigm perspective, this leads to inefficient fracturing, high pressure with shorter fracture length, and more fluid damage due to greater fluid invasion. The potential advantage, however, is a widespread zone of shear-tensile fracturing where permeability increases because the rock volume dilates or expands (dilatancy). This new paradigm is the focus of this article.

GeoMechanics International Inc. (GMI) has emphasized the pervasiveness of shear failure.10 The conventional concept of critical natural fractures is that conductive fractures, aligned with the maximum horizontal stress, SHmax, are those on the verge of failing (opening) in tension. GMI’s concept, however, is that tensile fractures are less likely to control flow compared with shear fractures and faults in many reservoirs.

The GMI concept is that conductive fractures are those on the verge of failing in shear. Such critical fractures will probably not align with SHmax (Fig. 4). Geothermal data also supports this conclusion when microseismic bursts have aligned in a direction at a significant angle to SHmax.

If the pore pressure stays below the minimum horizontal stress, Shmin, as is the usual geothermal situation, it seems that initial failure is shear failure on fractures at an angle to SHmax, and these are the permeable fractures. But in the oil and gas context, where pore pressure generally exceeds Shmin, both shear and tensile failure can occur and the situation is more complex.

In the special case of the Barnett shale, shear failure should not occur (theoretically) in the production sweetspot, because natural fractures align with in situ stresses. But shear failure does occur everywhere, implying that natural fractures are misaligned with local stress or differential forces can shift or rotate large matrix blocKs, causing shear failure.

Also, natural fractures align roughly with Shmin and not SHmax.11 This condition may favor shear failure because the natural fractures may block and divert the growth of a tensile fracture; and thereby create a fracture network.

When the stress field has local variations and orientation, it is possible for the growing fracture to depart in different directions, which may include shear failure, and create a local network. This is one explanation for local variations observed in microseismic patterns (although the far-field stress will govern the overall direction).

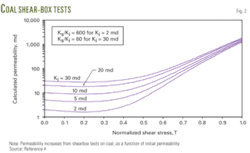

Our mental model for shear stimulation in a naturally fractured formation is a central induced fracture, aligned with SHmax, surrounded by an elliptical diffuse zone of shear-tensile failure that has enhanced virgin permeability (Fig. 5). The central fracture may be a discrete fracture or it may be reduced to being just a part of the diffuse zone.

Keys to shear stimulation

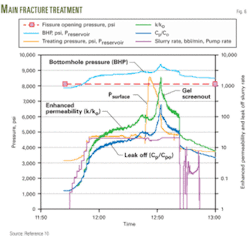

There are four keys needed to model and predict shear stimulation (Fig. 6).12 Many studies have investigated each key separately. Some modeling approaches have integrated some of these keys.13-15 The integration of the four keys, however, is difficult.

As previously mentioned, this article will discuss the first key while the concluding part of this two-part series will cover the remaining three keys.

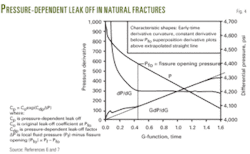

The first key involves laboratory studies that investigate permeability enhancement from shearing. Fig. 7 illustrates the concept. It shows that shear stress acting along a natural fracture or weak plane can cause slippage.16 If the surface is rough, this leads to gaps and enhanced permeability. The term for this mechanism is dilatancy.

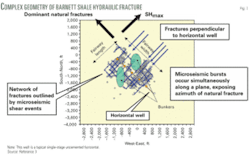

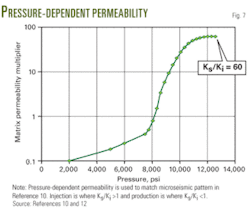

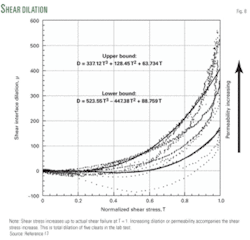

In the lab, shear-box tests (direct shear tests) can measure dilation and associated permeability increase. Fig. 8 is a good illustration for coal in which dilation mostly increases with shear stress up to shear failure.17 Note however, that for the lower curves, where normal stress is higher, the dilation can decrease before it begins its large increase.

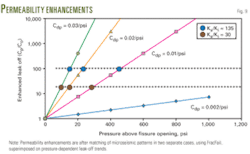

Fig. 9 shows the amount of permeability increase for different initial coal permeabilities, Ki. The increase is very large: 60 times for Ki = 30 md, and 600 times for Ki = 2 md.

The permeability enhancement is greater if the initial permeability is lower. It is also interesting that the permeabilities at failure 1,200-1,900 md are not very sensitive to their initial permeabilities.

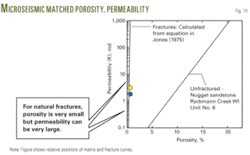

Terra Tek has generalize these lab results into an equation for permeability enhancement Ks/Ki, both in md, in terms of ds the single-fracture dilation in µm, and aKi where a is the fracture spacing in cm.17 If we assume a similar relationship applies to hard rock as well as coals, the implications for shear stimulation in the field are:

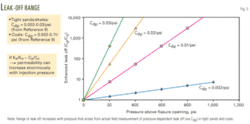

- A smaller aKi (or equivalently a smaller fracture width) gives a larger Ks/Ki (Fig. 10)

- A larger dilation ds is better. One should make sure that shear stress on a natural fracture increases past yielding and all the way to failure.

- Induce failure as far as possible out into the reservoir, for example with a pore pressure increase.

Fig. 10 shows that the permeability enhancement is greatest in granites, which is important in geothermal applications. Tight sands are intermediate. Coals and dolostones exhibit the smallest permeability enhancement, although as Fig. 9 shows, the permeability enhancement in coals can still be very large.

The measurement of permeability enhancement by shearing in the lab is a key for predicting shear stimulation in the field. We know how to predict a zone where shear failure occurs after injection into a well, but one needs lab measurements to predict the degree of permeability increase. Researchers still have not done this integration properly, to our knowledge.

An approximate approach assumes a pressure-dependent permeability function (for natural fractures) and uses this as a free parameter to match both shear failure zone (microseismic burst pattern) and well production.13

The pressure-dependent permeability during injection would include permeability enhancement due to shearing (dilatancy). It could also include presumably other mechanisms such as elastic pressure-dependent permeability (ballooning of fractures), or tensile failure. This lumped approach is the approach we have used in our modeling.

In future work, we envisage an approach in which lab measurements of shear failure and permeability enhancement are directly input into shear stimulation models.

References

- Aud, W., et al., “The effect of viscosity on near-wellbore tortuosity and premature screenouts,” Paper No. SPE 28492, SPE ATCE, New Orleans, Sept. 25-28, 1994.

- Nelson, E., et al., “Using geological information to fracture optimize stimulation practices in the Cooper Basin, Australia,” Petroleum Geoscience, Vol. 13, No. 1, February 2007.

- Mayerhofer, M., “Hydraulic fracture mapping and engineering in the Barnett shale,” SPE ATW on Unconventional Gas Reservoirs, Keystone, Colo., Apr. 21, 2006.

- Olsen, T.N., et al., “Improvement processes for coalbed natural gas completion and stimulation,” Paper No. SPE 84122, SPE ATCE, Denver, Oct. 5-8, 2003.

- Wold, M., et al., “Cavity completion for coalbed methane stimulation—an integrated investigation and trial in the Bowen basin, Queensland,” Paper No. SPE 30733, ATCE, Dallas, Oct. 22-25, 1995.

- Barree, R., and Winterfeld, P., “Effects of shear planes and interfacial slippage on fracture growth and treating pressures,” Paper No. SPE 48926, SPE ATCE, New Orleans, September 1998.

- Kilstrom, K., et al., “Minimizing multiple fractures in coalbed methane fracturing operations,” Paper No. SPE 38859, SPE ATCE, San Antonio, Oct, 5-8, 1997.

- Diamond, W.P., “Underground observations of mined-through stimulation treatments of coalbeds,” Coalbed Methane, SPE Reprint Series No. 35, 1992.

- Palmer, I., et al.: Coalbed methane well completions and stimulations, Hydrocarbons from Coal, editors B.E. Law and D.D. Rice, AAPG, Tulsa, 1993.

- Dell’Angelo, L., “The value of constraining the state of stress for improved well productivity through fracture permeability,” SPE-ATW on Unconventional Gas Reservoirs, Keystone, Colo., Apr. 21, 2006.

- Simon, Y.S., MS thesis, Texas A&M, College Station, Tex., December 2005.

- Palmer, I., “Geomechanics of shear stimulation,” Tight Gas Completions: Technology Applications and Best Practices, SPE ATW Keystone, Colo., Dec. 12-14, 2007.

- Ji, L., et al., “A new approach to hydraulic fracture modeling—fully coupled with geomechanical and reservoir simulation,” Paper No. SPE 99428, Europec/EAGE Conference, Vienna, June 12-15, 2006.

- Rahman, M.K., et al., “A shear-dilation-based model for evaluation of hydraulically stimulated naturally fractured reservoirs,” Intl. J. Num. & Anal. Methods Geomec., Vol. 26, 2002, pp. 469-97.

- Palmer, I., et al., “Modeling shear failure and stimulation of the Barnett shale after hydraulic fracturing,” Paper No. SPE 106113, SPE Hydraulic Fracture Conference, College Station, Tex., Jan. 29-31, 2007.

- Chipperfield, S., et al., “Shear dilation diagnostics: a new approach for evaluating tight gas stimulation treatments,” Paper No. SPE 106289, SPE Hydraulic Fracturing Technology Conference, College Station, Tex., Jan. 29-31, 2007.

- “Cavity completions for enhanced coalbed methane recovery,” TerraTek, GRI-95/0432, June 1996, pp. 6-1 to 7-3 and E-1 to E-11.

The authors

Ian Palmer ([email protected]) is a partner of Higgs-Palmer Technologies LLC in Tulsa and resides in Albuquerque, NM. He consults in shear fracture modeling, hydraulic fracturing, coalbed methane, sand prediction, and general geomechanics. Recently, Palmer was a geomechanics specialist with BP PLC in Houston. He is an originator and principal of a consortium of 10 companies investigating how to enhance permeability in low-permeability formations, and delivers courses in completion and stimulation of tight-gas shales or coalbed methane. Palmer has a BS and PhD from the University of Adelaide, Australia. He is an SPE member.

John Cameron is a consultant in drilling and completions for PCM Technology Inc., Tulsa. He previously worked for Amoco in hydraulic fracturing materials, drilling fluid hydraulics and cuttings transport, formation damage remediation, and completions optimization. He currently worKs as consultant for Eclipse Petroleum Technology, Houston. Cameron has a BS in mathematics and MS in chemical engineering from Ohio State University and a PhD in chemical engineering from the University of Michigan. He is a registered professional engineer.

Zissis A. Moschovidis is the managing consultant at PCM Technical Inc. in Tulsa and worKs in the areas of geomechanics, wellbore stability, cuttings injection, and hydraulic fracturing. Previously he worked at the Amoco research center and the structural analysis department of Ford Motor Co. Moschovidis has a degree in civil engineering from National Technical University of Athens, Greece, an MS in structural engineering from Imperial College of Science and Technology, London, and a PhD in engineering mechanics from Northwestern University. He is a registered engineer in Oklahoma, Michigan, and Greece and is a member of SPE.

Jorge Ponce is a completion and stimulation specialist for Pan American Energy, a BP PLC joint venture in Argentina. He previously was with the EPTG group (R&D) in BP Americas, Houston where he led a project to develop new completion and stimulation options for complex wells in unconventional reservoirs. This project evaluated shear stimulation as an option to enhance permeability and productivity in CBM reservoirs. Previous he worked for Amoco in different positions in drilling, completion, well testing and gas production engineering. Ponce has a degree in chemical engineering and a postdoctoral degree in project management. He is an SPE member.