New mud pump increases capacity, minimizes vibration

As oil and gas fields mature, operators must drill wells with large offsets, long laterals, and extended reach applications using rotary steerable systems, mud motors, and bottomhole assemblies that require higher mud pump pressures and flow rates.

To meet this demand, drilling contractors are building and renovating rigs with increased mud pumping capacity, giving drilling engineers greater flexibility with bottomhole assemblies, without having to carefully budget around hydraulic system limitations.

LeTourneau Ellis Williams Co. Inc. (LEWCO) has developed its new W-3000 mud pump model for oil field drilling service. Described by LEWCO as the world's largest mud pump, the W-3000 can handle power input of up to 3,000 hp (Fig. 1).

The pump provides a maximum working pressure of 7,500 psi and, with its 16-in. stroke at 100 strokes/min, a maximum pump rate of 1,044 gpm.

Rowan Cos. Inc. plans to install three pumps each on the Gorilla VIII and the Tarzan class Scooter Yeargain jack up drilling rigs, giving each rig 9,000-hp total mud system capability. The two rigs are scheduled for completion and deployment in the third quarter 2003 and 2004, respectively.

Don Vogelsang, executive vice president of sales for LEWCO, said the company will begin actively marketing the new mud pump after it has been installed and operated in a commercial drilling application.

Atwood Oceanics Inc., Houston, has placed an order for three smaller, but similar design, 2,200-hp triplex piston mud pumps and drives, for their recently announced rig, a Keppel FELS Ltd. MOD V enhanced B-class jack up drilling unit being built in Singapore.

The rig, built to work in up to 350-ft water depth, will mobilize upon completion in 2003.

Power end

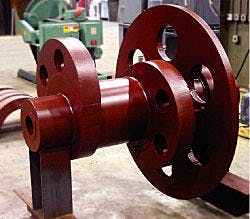

The manufacturing plant builds the pumps with inherently balanced eccentric crankshafts made of heat-treated, forged-alloy steel for maximum toughness (Fig. 2). The inherent balancing provides for smooth operation, reduced noise and vibration, and extended bearing and crankshaft life, says the company.

A nickel coin remains on its edge atop the fluid end of the 3,000-hp mud pump, operating at 2,200 hp while pumping water, at the Houston test facility (Fig. 3).

Additional benefits of the balanced crankshaft design include reduced maintenance and decreased or eliminated vibrational inputs to structures or equipment making contact with the pump, says LEWCO.

A welded power frame, made from high-strength, stress-relieved steel, is ribbed and gusseted to reduce weight without sacrificing durability.

Forged and heat-treated alloy steel pinions and gears feature double helix or herringbone tooth design for better load transmission and quiet operation.

To ensure fail-safe lubrication protection, even at very low operating speeds, the pumps have an internal splash-gravity feed, internal gear-driven pump, and external electric motor driven equipment for triple redundant lubrication.

Precise alignment between the crankshaft and crosshead under maximum load minimizes wear and extends pump life.

Close-grain cast iron crossheads and guides provide fatigue-cracking resistance.

The new pumps have heat-treated steel connecting rods with double-row cylindrical roller bearings in the crosshead end and single-row cylindrical bearings in the crankshaft end to minimize wear and friction under severe operating conditions.

Fluid end

The factory will adapt most third party fluid-end modules to the mud pumps, eliminating the need for drilling contractors to stock fluid end parts from several manufacturers.

The factory can supply heat-treated, internally hardened forged alloy steel modules, if the drilling contractor doesn't specify third party fluid ends.

Contractors can specify wear-resistant, API-standard liners, pistons, valves and seats, with a wide choice of options available for standard-equipment slush-type pistons, hardened or stainless steel valves, and elastomer-insert valve seats.

One may also specify job-matched plungers, available in colmonoy, ceramic, tungsten carbide, and a range of other materials, to meet specific requirements.

Test facility

The company has built and commissioned a full load pump-testing facility at its manufacturing site in Houston, which it says is the only one owned and operated by a pump manufacturer.

The company requires that each pump undergo full-load testing prior to shipment, which LEWCO says is the final quality-control step to ensure the customer is taking delivery of the pump they selected based on the manufacturer's published pump ratings.

Tests are conducted up to 3,000 hp or 7,500 psi on pumps driven by AC or DC electric motors.

A purpose built computerized instrumentation system monitors the pump tests.

The system displays information on the various parameters being monitored in real time, as follows:

- Bearing temperature, two readings at the pinion and two readings at the mains on the crank.

- Liner water temperature.

- Oil temperature.

- Discharge pressure.

- Sound level, db.

- Strokes/min.

- Pinion rpm.

- Driver rpm.

- Driver hp.

- Hydraulic hp.

- Vibration X and Y axis.