Intelligent completion provides savings for Snorre TLP

Because of restricted intervention capabilities while new wells are being drilled, Norsk Hydro AS installed an intelligent well system in the Snorre field, 210 km northwest of Bergen, Norway.

The Baker Oil Tools intelligent well system (InForce system), installed in August 2000, can remotely control hydraulically actuated sliding sleeves. The system also includes a Wood Group's (Aberdeen) downhole permanent pressure and temperature monitor. With the system, Norsk Hydro can detect downhole problems sooner and control flow quickly in response to changing downhole conditions.

Installation details

Since April 2000 alongside the main platform rig on the Snorre tension leg platform (TLP), Norsk Hydro has had a second rig in operation, Procon Drilling Services AS's (Bergen) Rubicon ram rig (Fig. 1). The second rig accelerates drilling of new wells, but having two rigs on the platform has severely restricted space for workover operations.

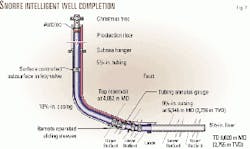

The producing well with the intelligent completion system was completed with selective sliding sleeves for each reservoir zone and a main completion string of 51/2-in., 20-lb/ft tubing (Fig. 2).

Each hydraulically operated sliding sleeve can be activated from surface by two hydraulic control lines. A multifeed-through packer, accommodating control-line passages, allowed multiple sliding sleeves to be placed within the precise zones of interest. By pressurizing either the open or close line, one can open or close a sleeve within about 5 min.

During the pressurization of one line, the other line serves as a balanced line to allow a predetermined amount of displaced hydraulic oil to be collected at the surface. The downhole permanent gauges, in conjunction with this simple concept, provide a clear and positive indication of whether the sliding sleeve has successfully closed or opened.

A dual-gauge mandrel was designed to accommodate bypass of two control-line flat-packs. This adds flexibility for placing the gauges above the sliding sleeves, if needed.

The hydraulically operated sliding sleeves control reservoir flow from two zones in the Upper and Lower Statfjord. Both zones are completed within 95/8-in. casing. The remaining flow is from a perforated 51/2-in. liner that is not actively controlled.

A Baker multicycle fluid-loss control valve, which is below the sliding sleeves and gauges, prevents fluid entering into the lower zones in the 51/2-in. liner and allows independent pressurization of the zones in the 95/8-in. casing.

Reservoir area

The well is completed in an area south of the central reservoir block. This new area has had only one exploration well drilled and is not in direct communication with the main field. The original development prognosis for this area, which is contained within two faults, said that three wells would be needed for reservoir characterization.

Only limited reservoir pressure support was expected to be available for the producing well. This knowledge led Norsk Hydro to include remote flow control of zones within the well. Norsk Hydro had the further objective to gather data while producing the well to enable it to determine the requirement for placement and design of other wells for this area.

The producing well was drilled through the northern and southern reservoir segments with its heel in the northern area. The southern reservoir segment is separated by a fault and the toe of the well was targeted for this area.

Norsk Hydro did not include remote control for the toe but included a flapper valve in the production tubing to prevent injection into the toe. The well design including remote sleeves, pressure and temperature gauges, and the fluid-loss control valve.

The initial objective of reservoir characterizing for the new southern block was to produce from the toe while leaving the upper zones shut in by the closed remotely operated sliding sleeves. This allowed the reservoir section south of the fault to be produced, while at the same time, pressure and temperature available from the annulus gauge could be recorded from the upper zone north of the fault. This information provided knowledge on the connectivity across the fault.

Injection need

A supporting injector well for the producer could not be scheduled until the first quarter of 2002 because of the busy drilling schedule. As a result, production was predicted to last only a few months before critical reservoir pressure was reached.

Loosely consolidated sands are a threat to Snorre wells, and it is not recommended to produce the well below this critical pressure. Damage to some wells has already been experienced because of sand production.

The remotely operated sleeves and the fluid-loss control valve permit gas injection within the well to maintain pressure without the immediate need for a dedicated injection well. In this process, pressure is first built up by injecting into the heel of the well. Then the sleeves are closed remotely.

This injection provides sufficient pressure to produce from the toe of the well without lowering the reservoir pressure below critical. Without this capability, production may have had to be deferred until the injector support for the producer was completed in the first quarter of 2002.

Remotely operated sleeves provide the further advantage of being able to inject gas into the upper zones and then close off the upper zones. This prevents backflow and possible formation in the near wellbore of asphaltene blockage that would have to be removed by well intervention.

Cost savings

The excellent production rates from this well make the downtime resulting from intervention work or shut-in highly undesirable.

Intervention costs in the North Sea typically are substantial. A minimum of 9 days of work is usually needed, with costs for rig, coiled tubing unit, associated services, and deferred production. In any case, on Snorre well intervention work could not be scheduled for several months.

Norsk Hydro quickly determined the productivity index (PI) of the lower Statfjord reservoir by shutting in the zone remotely and monitoring pressure and temperature data during a build up. Without remote sleeves and monitoring, the PI determination would have required well intervention for accurate results.

The greatest benefit of this completion method is its ability to provide data for optimizing the planning of the support injector for the producer. Norsk Hydro used the data gathered from the well during the first 6 months of production and the "huff and puff" pressure support to determine the optimum position for the planned injector.

Without such a detailed understanding of the well's production, the support injector may have been imprecisely positioned and it could have taken several years to receive the desired production results.

The intelligent well system possibly not only saved the cost of a potential sidetrack but also the cost of an entire injector well if the initial injector had been located incorrectly.

Other benefits

On Snorre, the first 6 months of production are the most important because during this time the data collected helps determine the location of future development wells. Therefore, a simple, reliable system was critical for acquiring the required data.

An on-off control system has been sufficient for Norsk Hydro to gather data and control the well. With this data, it has learned that production from the Lower Statfjord is most efficient when the Upper Statfjord is closed, although choking the Upper Statfjord may also provide satisfactory results.

The solution implemented for this Snorre well represents a step change in cost-effective completions, reservoir management, and planning. The completion can be manipulated to provide the optimal mechanical configuration for maximum sustainable production. Permanent downhole monitoring provides real time, continuous information for these remotely operated downhole tools. The major benefits realized are:

- Reduced operating costs through zero well intervention.

- Accelerated field production.

- Tuning of well configuration to optimize production throughout the life of the reservoir.

- Ability to shut off watered-out zones.

- Production control through variable permeability zones, whether producer or injector.

- Improved accuracy of reservoir reserves calculations.

- Identification of reservoir boundaries.

- Determination of optimum future well placement.

- Improved personnel safety through reduced intervention operations on live wells.

- Minimized risk to the well, inherent in any intervention.

Acknowledgments

The author thanks Line Torset Skarsholt and Steinar Samuelsen of Norsk Hydro AS for their help with this article.

The author-

Craig Coull is a region engineer with Baker Oil Tools in Stavanger. He is responsible for the development and implementation of intelligent well solutions within the Scandinavian area. Coull has a BEng honors degree in mechanical and offshore engineering. He is an associate member of the Institution of Mechanical Engineers.