New gravel-pack technique reduces sand production in Niger Delta wells

In the Niger Delta, off Nigeria, field experience based on a learning curve derived from gravel packing in conventional wells proved effective for improving gravel packs in monobore and horizontal wells. Operators also reduced the need for remedial sand-control repairs by extensively applying coiled tubing in gravel packing procedures.

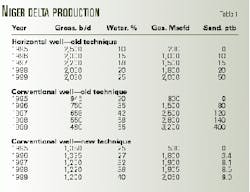

Well production histories comparing old prepacked slotted-liner methods with the new procedures show a reduction in sand cut to 9 lb/1,000 bbl (ptb) of crude oil from a previous 20 ptb.

Sand control

Gravel packing is the most accepted technology for sand control of unconsolidated reservoirs, but it is a challenge in horizontal wells, which have increase productivity, added recoverable reserves, and improved overall cost-effectiveness of many field operations.1-3 This is particularly true in the Niger Delta where the sand cut limit is 10 ptb.4

Many procedures for gravel packing design depend on physical and numerical models, which are limited by problems of scale and research costs.5 6

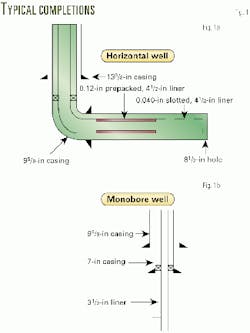

Gravel packing prevents formation sand in the fluid from the reservoir from being produced to surface. But in highly deviated and horizontal wells (Fig. 1a), the gravel pack may not be effective because of nonuniform placement of the gravel around the screen and in the perforations.7 8

Design criteria for gravel packing include pumping rate of the slurry, number of perforations, clean completion fluids, and viscous fluid-loss control pills.9

Monobore, slim hole, wells cost less to drill and complete because they require less cement and fewer tubulars. The wells are flexible in terms of maintenance and cost less to service than horizontal wells because special tools are often not required. These wells can be effectively re-entered with coiled tubing for correcting failed sand control (Fig. 1b).

Niger Delta techniques

In the Niger Delta, operators typically perforate the intervals to be gravel packed with the well in an overbalanced state and then run a wash assembly to clean out the perforations. Sometimes they cut a window in the portion of the casing across the pay zone before running an underreamer to sweep the formation sand out of the immediate vicinity of the casing before running the gravel-pack liner assembly. During the gravel-pack operation, gravel fills the cavity washed out by the underreamer.

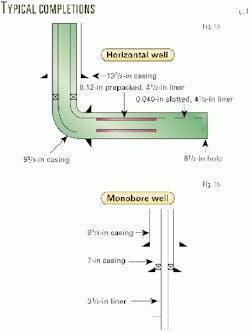

Production histories show that this method in horizontal, monobore, and conventional wells has not been satisfactory (Table 1 and Fig. 2a). Production gradually declines, while water-cut, GOR, and sand-cut increase.

This can be explained by an ineffective prepacked liner or slotted liner.

In the new gravel-pack technique, the operator first perforates the wells underbalanced and then prepacks the perforations before the actual internal gravel pack (IGP) of the gravel-pack screen or casing annulus. The technique involves the following operations:

- Perforate the casing with tubing-conveyed guns run in the well on a drillstem test assembly.

- Perforate underbalanced and produced the well for 20 min before shut-in.

- Perform an injection test by squeezing back the produced formation fluids and 3 bbl of prepad with 13.6 bbl of slurry and additive, 20/40 gravel, and 70 bbl of filtered brine.

- Prepack the perforations with 14.9 bbl of additive, sheared by circulating it through a 20/64-in. choke at a pump pressure of 2,000 psi.

- Filter the additive through a cartridge filter unit equipped with a 2-µm cartridge.

- Run a sand suspension test on the additive to ensure that there is no cross linking. The pad volume is removed from the blender, while mixing continues and 20/40 gravel is added to the blender.

- Spot and squeeze the gravel into the perforations.

- Clean out the wellbore.

- Run the gravel-pack liner assembly into the wellbore.

- Repeat the injection test and, when successful, the IGP operation includes 14.9 bbl of additive mixed in the blender and filtered through the 2-µm cartridge unit. A sand suspension test verifies no cross linking of the 20/40 gravel added to the blender before the gravel is squeezed into the gravel-pack screen and casing annulus.

- Clear the wellbore to run the final completion accessories.

New technique results

The production histories of wells gravel packed with the new method do not display the extreme trends illustrated in six wells gravel packed with previous techniques (Table 1 and Figs. 1b-1c).

In Table 1, the decrease in production rate, from 1,380 to 1,200 b/d, for the well gravel packed with the new technique might be explained by the increase in water cut to 40% from 25% caused by an active water drive. The 9 ptb sand-cut average is less than the 10 ptb limit set for the region.4

For the wells, the initial production prognosis, with the prior gravel-pack technique, was 1,100 b/d at 10% bs&w. Because the wells initially produced more than 1,350 b/d, it can be assumed that the new gravel-pack technique diminished formation damage effects.

The previous techniques caused expensive reentries for remedial workover operations as collaborated in earlier findings that determined that impairment of the internal gravel packed wells occurs during the placement of gravel.11

The casing program for horizontal wells should incorporate cementing the production string in place. The casing should be perforated along the drain length under drawdown with tubing-conveyed guns run on a drillstem test assembly. The liner and gravel-pack screen should be a repacked slotted liner set. The slot sizes should correspond with the formation grain sizes.

Good results have been obtained in monobore wells when the prepacked liners are run before the gravel-pack screens with coiled tubing. Coiled tubing retrievable prepacked gravel-pack screens should be used in the liner.

Acknowledgment

The author thanks the Humboldt Foundation for its financial support and the computing facilities provided at the Institute of Petroleum Engineering, Clausthal Technological University, Germany.

References

- Thakur, G.C., "Horizontal Wells Technology-A Key to Improving Reserves," JCPT, Vol. 38, No. 10, October 1999, pp. 55-60.

- Vozniak, J.P., Mathis, S.P., Hogg, W.C., and Ratterman, E.E., "Successful Horizontal Drilling and Gravel Packing in Deep and Ultra-Deepwater," Paper No. 67750, SPE/IADC Drilling Conference, Amsterdam, Feb. 27-Mar. 1, 2001.

- Appah, D., "An Assessment of Sanding Wells at Kirovneft," Journal of Institute of Engineers (India), Vol. 78, March 1998, pp. 39-43.

- Appah, D., and Ichara, M., "Empirical Model Determines Energy Required to Clean Sand from Wellbore," OGJ, Feb. 28, 1994, pp. 36-38.

- Shroeder, D.E., and Kelley, T.K., "Horizontal Well Gravel Packing Model," Paper No. 30529, SPE Annual Technical Conference and Exhibition, Dallas, October 1995.

- Bouhroum, A., Bai, M., Appah, D., and Ghofrani, R., "Experimental Investigations of Gravel-Pack Damage," Journal of Crude Oil, Natural Gas, and Coal (Germany), Vol. 111, No. 2, February 1995, pp. 61-66.

- Klein, H.H., Cooper, G.D., and Nelson, S.G., "Design and Evaluation of Gravel and Frac Packs with a fully Three-Dimensional Wellbore Simulator," Paper No. 35032, SPE Formation Damage Control Conference, Lafeyette, La., February 1996.

- Oyeneyin, M.B., Peden, J.M., Hosseini, A., Guowu, R., and Bigno, Y., "Optimum Gravel Sizing for Effective Sand Control," Paper No. 24801, SPE Annual Technical Conference and Exhibition, Washington DC, Oct. 4-7, 1992.

- Shyrock, S.G., "Gravel Packing Studies in a Full-Scale Deviated Model Wellbore," JPT, March 1983, pp. 603-09.

- Robinson, C.E., "Monobore Completions for Slim-Hole Wells," JPT, Vol. 46, No. 9, September 1994, pp. 794-99.

- Welling, R.W.F., Jonathan, P., Reijnen, P.H.F., and Samuel, A.J., "Quantifying the Factors Influencing Gravel Placement and Productivity of an Internally Gravel Packed Completion Based on Field Data Analysis," Paper No. 30113, European Formation Damage Control Conference, Den Hague, May 15-16, 1995, pp. 369-78.

The author

Dulu Appah is with the petroleum engineering department, University of Port Harcourt, Nigeria. Currently, he is a Humboldt guest researcher on fines migration in gravel-packed wells at the Institute of Petroleum Engineering, Clausthal University of Technology, Germany. He previously conducted research on gravel pack optimization at the University of Oklahoma, Norman. Appah holds an MS in petroleum engineering from the Azerbaijan Petroleum Academy, Baku, and a PhD in petroleum engineering from the University of Port Harcourt, Nigeria.