Syntactic foam improves deepwater flowline thermal insulation

The industry has started installing thermal insulating material for deepwater subsea equipment, flowlines, and pipelines to ensure hydrocarbon flow under adverse conditions.

Experience shows that syntactic foam can in many cases offer significant engineering and economic advantages compared to more-conventional insulation.

To realize the full benefit of these materials, one must carefully select the ingredients and optimize all relevant properties with a systems approach to the manufacture, assembly, and installation.

Syntactic foam

Syntactic foam has been used for more than 30 years in the offshore industry, primarily as a buoyancy material for supporting risers and in various kinds of floats and buoys.

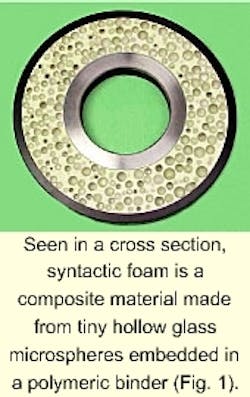

The foam is a composite material made from tiny hollow glass microspheres embedded in a polymeric binder (Fig. 1). High compressive strength and low density are the properties that make syntactic foam an efficient buoyancy material, and low thermal conductivity is a byproduct of its construction.

Given its thermal efficiency and water resistance, syntactic foam is a natural choice for insulating subsea equipment. The materials used in its construction, however, must be selected carefully with an eye toward operating conditions.

Applications

Subsea production of hydrocarbons is prone to blockage by paraffins or hydrates that can form when the fluid temperature falls below some critical level. An important aim of flow assurance technology, therefore, is to conserve the heat of the fluid and prevent excessive cooling, even during shutdown periods.

This has become an increasingly important concern as production has moved into deeper water and longer flowlines have been required, and a variety of different insulation methods have evolved.

The following components are now typically insulated:

- Wet trees and valves are routinely insulated. Key issues include high temperature, differential thermal expansion and contraction, and the necessity of some parts to move or to be serviced or replaced while in service.

- Jumpers are also frequently insulated. These pipes are often of complex curvature and usually require insulation materials with a great deal of flexibility. Speed and ease of installation are important objectives.

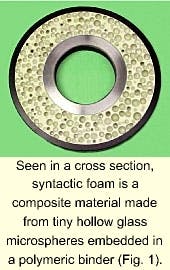

- Sleds and pipeline-end manifolds (PLEMs) often require not only thermal insulation, but also buoyancy to aid subsea installation. Syntactic foam can be designed to combine the buoyancy and insulation functions (Fig. 2).

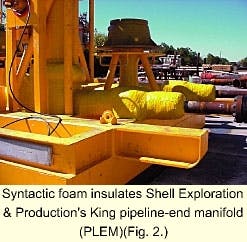

- Risers and flowlines often need a high degree of insulation as well (Fig. 3). The insulation system must be compatible with the desired lay method and fabrication technique, and buoyancy may be an issue. Long service life, of course, is always a major objective.

Materials selection

The characteristic ingredient of syntactic foam is the tiny microsphere filler that imparts much of its thermal and physical behavior. Glass micro- spheres, typically 100-200 µm in diameter, retain much of their strength at elevated temperature. Certain types of ceramic microspheres also have excellent resistance to hot water, but their densities and thermal conductivities are not acceptable for many applications.

Larger fiberglass macrospheres, 6-12 mm in diameter, are often used in buoyancy applications to lower density and improve the cost effectiveness of syntactic foam castings. Unfortunately, the fiberglass walls of conventional macrospheres are affected adversely by high temperature, which limits the so-called composite insulation materials (containing macrospheres) to temperatures of about 100° C. or less.

Research is continuing to develop new, high-temperature-tolerant macrospheres for insulation purposes.

The binder resin, a polymerized plastic material, forms the matrix that glues the various filler ingredients together. Choices include various rigid and semi-rigid types of epoxy, and elastomeric plastics such as polyurethane.

The more rigid the binder, the better it reinforces the hollow spherical fillers and retains its strength at elevated temperature. A flexible binder, on the other hand, will resist cracking and permit the pipe to be bent, or in some cases, reeled. The degree of adhesion to the pipe or substrate is often important, as is resistance to impact and abrasion.

The selection of the binder resin is strongly influenced by its ability to withstand the long-term effects of hot water. Many plastics exhibit thermal degradation that can only be revealed by testing for long periods of time.

Testing

Thorough testing of syntactic foam insulation is critical for a successful application. The challenge is that little long-term data are available, and the established standards and specifications are not always applicable.

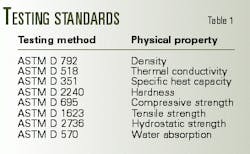

Table 1 list the standards commonly applied to insulation materials, and Fig. 4 shows a typical thermal-conductivity measuring device.

The following is a brief summary of the testing hierarchy that is now slowly emerging among users and suppliers in the industry:

Initial screening involves immersion of small samples in hot water at atmospheric pressure to detect any signs of swelling, warpage, embrittlement, or hydrolysis. Accelerated aging is possible by raising the water temperature, but slightly less than 100° C. is the practical limit for open water baths.Depth vs. density

The strength of foam is proportional to density. Achieving an optimal combination of thermal conductivity and hydrothermal resistance requires careful selection of both binder and fillers.

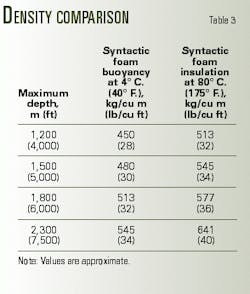

Table 2 compares typical densities of syntactic foam buoyancy materials and equivalent syntactic foam insulation and Table 3 lists expected thermal properties.

Special challenges

The following three areas pose probably the greatest technical challenges facing use of syntactic insulation as subsea applications go deeper and hotter:

1. Hydrothermal aging. All plastics exhibit some degradation when exposed to hot, high-pressure water. The degradation effect must be taken into account if the insulation is to last through the design service life.

Hydrolysis is the gradual breakdown of the plastic's polymeric chain, resulting in loss of properties. Binder materials vary widely in their resistance to hydrolysis, depending on formulation and processing, and behavior is very dependent on specific conditions.

Several industry-wide programs are currently under way to promote long-term testing and broaden our understanding of these phenomena.

2. Filler stability. Glass microspheres also suffer to some extent from hydrothermal effects. If the glass used to form the microspheres contains too much free sodium or some other water-soluble ion, it will exhibit much the same behavior as described previously, which is gradual loss of properties, breakage, and dissolution.

Special high performance microspheres, coatings, and coupling agents are available that ensure stability under extreme conditions, and suppliers of glass microspheres are working to create further improvements. The same industry groups cited previously are addressing the issue as part of their materials studies.

3. Flexibility and cracking. A certain amount of flexibility is desirable in an insulation material, so that it accepts bending and differential expansion under thermal cycling. Materials that are too rigid will crack in service, raising the possibility of convective heat losses.

The extent to which such cracks actually affect the overall insulating value of the system is a complex question requiring analysis. Flexibility becomes even more important in the cases of flexible risers, or of reel laying of rigid flowlines.

The only practical solution for highly flexible applications at this time is to employ an elastomeric resin binder in place of more rigid materials.

Advantages

Syntactic foam as an offshore buoyancy is in service in more than 3,000-m water. In deepwater insulation applications, it offers a number of advantages over more conventional materials, based largely on its unique fine-celled structure and high strength-to-weight ratio, as follows:

- Low density. In most cases, syntactic foam provides the lowest density solution to any buoyancy or insulation requirement, at any depth.

- Low thermal conductivity. Again, in most cases, syntactic foam offers the lowest thermal conductivity at any depth, as compared to alternative materials.

- Virtually zero creep. Unlike other insulation materials, especially those based on thermoplastic foam, syntactic foam is inherently stable and does not creep under pressure.

- Integral buoyancy. The low density of syntactic foam permits a large amount of buoyant lift to be designed into the insulation system, if desired.

- Ruggedness and durability. Its great compressive strength makes syntactic foam resistant to crushing and mechanical damage during storage, handling, and laying.

- Adaptability. Because syntactic foam can be manufactured by several methods and in many forms, it can be adapted to any insulation requirement.

- Cost effectiveness. In many cases, syntactic foam has proven to be the lowest cost solution to insulating flowlines and subsea equipment, often saving users hundreds of thousands of dollars per project.

Economics

Aside from its technical performance advantages, designers select syntactic foam because it is often the least-cost solution to complex subsea problems. For example, no other material can successfully provide both buoyancy and insulation in a compact, volumetrically-efficient package.

To realize its full economies, however, the syntactic foam must be engineered with a systems approach that integrates materials science, processing, and mechanical design.

The cast-on-pipe process can apply syntactic buoyancy to a riser at lower overall installed cost than the traditional method of molding half-shells and strapping them onto the pipe. Similarly, pipe supplied with integral buoyancy and insulation is much less expensive and time-consuming to deploy than the conventional way of attaching clamps and assembling annular buoys onto the pipe at sea.

Table 4 compares the economics of various approaches to insulation and buoyancy.

Track record

The following list highlights applications of syntactic foam insulation in ultradeepwater production risers or flowlines. These applications are either already installed or in process of being installed.

It should be noted that this is only a small sampling of the total number of related projects at all depths, and does not include syntactic insulation applied to and in service on flexible risers, or a large number of miscellaneous subsea devices and equipment.

Future

Syntactic foam thermal insulation is still in its infancy. Much more experience will be gained over the next 2-3 years with syntactic foam on deepwater risers and flowlines. In addition, numerous projects are in the planning stages that will take this technology into deeper water and higher temperatures.

Several industry groups are at work, compiling information and drafting testing standards for the design and construction of these new systems. Suppliers are developing and testing new products for more demanding service.

The production industry has targeted 3,000 m as its next depth benchmark, and temperatures as high as 150° C. are being suggested.

Only time will tell how well these ambitious objectives are met, but it seems certain that the growing need for offshore oil and gas will continue to demand dramatic improvements in ultra-deepwater thermal insulation.

The authors

Lou Watkins is vice-president and chief technical officer of Cuming Corp., with more than 30 years of experience in syntactic foam insulation and buoyancy products. Watkins is a graduate of North Carolina State University and is a registered professional engineer in Massachusetts.

Elmer Hershey is general manager of Cuming Insulation Corp. and vice-president of Bayou Flow Technologies, based in New Iberia, La. He has more than 30 years of engineering management experience in the offshore oil and gas industry. Hershey is a graduate of Texas Tech University and is a registered professional engineer in Texas.