Pipeline installations critical in Cantarell oil field modernization

As part of a major upgrade and expansion project for the Cantarell oil field in the Gulf of Mexico, Petroleos Mexicano (Pemex) Exploración Y Producción is installing more than 400 km (about 250 miles) of new pipelines. The project is to increase crude oil production, better utilize gas, and improve reliability and operational safety in existing facilities.

This article describes construction of additional subsea pipelines to support the operating objectives of the Cantarell field. The engineering design and procurement aspects of the new pipeline network have been described previously.1

Cantarell

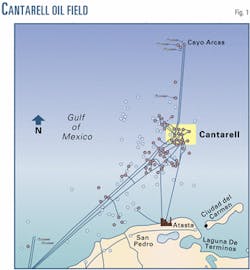

The Cantarell field, about 80 km offshore the Yucatan Peninsula in the Bay of Campeche, Mexico (Fig. 1), is the largest oil field in Mexico. Typical water depths range from 35 m in the south to 40 m in the north.

Cantarell consists of four major fields: Akal, Nohoch, Chac, and Kutz, in addition to the reserves in the newly discovered deeper Sihil Field. The largest reservoir, Akal, is the sixth largest in the world.

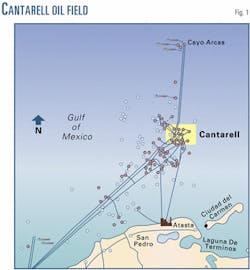

Over the past 20 years, reservoir pressure within Cantarell has declined by more than 60% (Fig. 2), leading to numerous operational difficulties in sustaining the target oil production rate, including falling well fluid levels and increased need for lift gas.

In addition to overcoming the effects of falling reservoir pressure, Pemex wanted to accomplish several key objectives:

- Increase the reserves.

- More than double oil production.

- Utilize all gas by adding sufficient compression and process capacity.

- Modernize the existing facilities to improve operational safety and efficiency.

The program has resulted in several major concurrent, integrated projects of unprecedented size and complexity, which together have created the largest offshore expansion of its type in the world. Major components of the Cantarell project include:

- Modernizing 39 existing platforms and constructing 26 new main platforms to increase oil and gas production and handling capacity.

- Developing two new complexes (Akal L and B).

- Building a floating storage and offloading facility for handling oil production.

- Building the largest nitrogen-generation plant in the world to supply 1,200 MMcfd of nitrogen gas to pressurize the oil reservoir (OGJ, Mar. 12, 2001, p. 41).

- Increasing gas handling capacity.

- Building offshore gas-treating platforms to generate lift gas.

- Modernizing Akal C to increase its gas compression and processing facilities to generate lift gas offshore.

- Modernizing the safety and control systems of all existing platforms and complexes.

- Laying more than 400 km of subsea pipelines to augment the existing 1,700-km network.

Pipelines at Cantarell

The Cantarell pipeline network transports a variety of petroleum products into, around, and out of the Cantarell field. These products include two-phase oil-gas mixture, oil, gas, lift gas, and nitrogen.

Two-phase (oil-gas) pipelines

A two-phase mixture of oil and gas is extracted from Cantarell production wells. The Cantarell field modernization and expansion has already significantly increased production, and production will increase further in coming years.

In general, the oil-gas mixture is collected from remote production platforms and transported to three centralized processing complexes: Akal C, Akal J, and Nohoch A, where first and second-stage separators separate the oil and gas.

Several new pipelines (Fig. 3) were constructed to transport the two phase oil-gas mixture from the new platforms and wells to the central complexes. More than 25 km of pipelines of various sizes were constructed to handle the new two-phase mixture.

Oil pipelines

After the two-phase mixture is separated into oil and gas, the oil is sent to tankers or to facilities ashore for processing and use within Mexico, or for export to other countries. The increase in Cantarell field production is creating significantly more oil to be handled and transported.

Before completion of the expansion and modernization of the Cantarell field, crude oil from Cantarell moved via pipelines to tanker berths offshore at Cayo de Arcas and to storage tanks ashore at Dos Bocas (Fig. 1) where part of the production is exported and the balance moves inland by pipeline.

As part of the Cantarell expansion projects, a floating storage offloading (FSO) vessel, the Ta'kuntah, was built at Cayo de Arcas. The FSO provides permanent storage capacity of 2.3 million bbl for loading onto tankers (the second largest operating tanker in the world). The FSO can offload 800 million b/d onto tankers (the world's highest cargo loading rate).

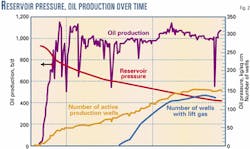

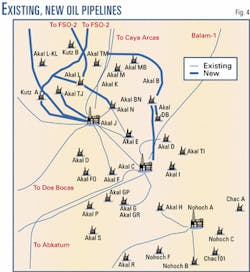

Fig. 4 shows a major pipeline constructed to transport export oil from Akal-J to the FSO. A new pipeline from Akal L connects into this line. Additionally, a new pipeline was built from Akal B and connected to one of the major lines from Akal J to Cayo de Arcas.

Gas pipelines

Before completion of the expansion and modernization projects, the gas removed from the two phase oil-gas mixture was sent ashore, processed, and returned offshore via pipelines for use as lift gas.

After completion of the new projects, most of the gas will remain offshore and be processed for use as lift gas, as discussed presently. The remaining gas will be sent ashore for processing and consumption. With the increase in Cantarell field production, additional gas is generated.

A total of 21 gas pipelines (Fig. 5) was built to transport the anticipated increase in produced quantity gas. Similar to the two-phase pipelines, these new gas pipelines transport gas to centralized processing facilities. A new pipeline was also built from Hohoch A to facilities ashore at Atasta. These new pipelines, with a combined length of 90 km, increase the total natural gas pipeline length to 310 km.

Lift-gas pipelines

Lift gas is commonly used in the oil producing industry to facilitate oil extraction from the reservoir. Pressurized lift gas is injected into the extraction wells where it mixes with the oil. The resulting mixture is lighter and therefore easier to lift.

The availability of lift gas at Cantarell is crucial for a sustained increase in oil production. There are about 205 production wells in the Cantarell field producing between 4,000 and 16,000 b/d. Each well requires, on average, approximately 2.8 MMcfd of lift gas.

The combined requirements of increasing reservoir pressure to maintain current production levels and increased production objectives made the supply of lift gas the single most critical activity for a sustained increase in oil production for the Cantarell field.

Lift gas is currently generated ashore, transported offshore via subsea pipelines, and injected into the wells via a "lift-gas ring" which circles the oil field. After the Cantarell expansion and modernization are complete, lift gas will be generated offshore and brought to the wells via pipeline.

The new pipelines will supply lift gas to the new production platforms and will supplement the lift gas supply to platforms in the north part of the field.

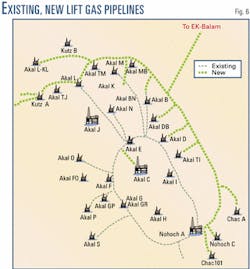

The existing lift gas pipeline system was 58 km long. The new lift gas pipelines will total 47 km consisting of the following (Fig. 6):

- A 20-in. OD lift gas pipeline ring from Nohoch A to Akal L.

- 14 new 12-in. feeder pipelines to six existing and eight new production platforms and two interconnections, one between the existing Line 156 and Akal L and the other between Line 156 and Akal C.

This new network will greatly improve operating flexibility and will allow increased production through the effective use of lift gas throughout the field.

Nitrogen pipelines

As discussed, reservoir pressure has decreased by more than 60% since exploitation of Cantarell began in 1979. In 1996, a redevelopment project was started aimed at increasing reserves through pressure maintenance by nitrogen injection.

A nitrogen plant capable of generating 1.2 bcfd was built on the Atasta peninsula. A new 85 km, 36-in. OD pipeline (Fig. 7) transports the nitrogen offshore to the Nohoch A complex where it is injected through nine nitrogen injection wells.

Pipeline construction

In general, pipelines are fabricated ashore in 20-m segments, coated with a protective corrosion-resistant material (inside and out), and then covered with a special concrete mixture to provide weight to counteract the pipeline's buoyancy.

These segments are loaded onto a pipe-laying barge and floated out to the beginning of the alignment. Segments are welded together incrementally and pushed off the barge onto a submerged pipeline guide. With the pipeline lying on the seabed, a special trenching machine moves along the sea floor, digging and backfilling the trench.

Submerged welds are conducted from a specially designed pressurized habitation structure positioned over the two pipes to be welded. Divers descend to the sea floor, enter the habitation structure through a hatch, and perform all necessary welding and testing.

Pipeline crossings typically have 1 m of clear vertical separation between the existing pipeline and the new.

Pemex has adopted an engineering-procurement-construction (EPC) execution strategy to construct the new pipelines, in which the EPC contractors are individually responsible for detailed engineering, selected procurement, and all fabrication, installation, hook-up, and commissioning of their respective projects and contracts.

The projects were competitively bid nationally and internationally under the Mexican Public Works Law on a fixed "unit rate by system" compensation methodology, with associated penalties for schedule delay. A total of 39 EPC contracts was executed for the Cantarell project overall, including 6 specifically associated with pipeline construction described here.

As of Dec. 31, 2000, a total of 45 pipelines with a combined length of approximately 328 km had been constructed (Table 1).

Increased production

Cantarell produced about 1.1 million boed in 1996. Overall production improvements and modifications since have allowed an increase in oil production of more than 25%, to around 1.4 million b/d. In 2001, the nitrogen-injection platform will increase oil recovery by approximately 20% of the original oil in place.

When the Cantarell expansion is complete, oil production will increase an additional 50%, and allow a 55% reduction in gas flaring. With an anticipated oil production capacity of approximately 2.2 million b/d in 2002, Cantarell production will be equivalent to the combined oil production from the 25 largest US fields.

Reference

- Speirs, A.P., et al, "Execution of EPC Submarine Pipeline Projects in the Cantarell Field," Offshore Technology Conference, Houston, May 1-4, 1999.