TECHNOLOGY Net 'fence' protects TLP production risers

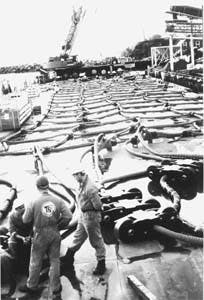

A fiber net on Conoco Inc.'s Heidrun tension leg platform will fence out boats or other floating objects that might endanger the production riser pipes and controls suspended under the TLP. The Heidrun TLP, in Block 6507/7 off mid-Norway, is said to be the largest floating concrete structure ever built. The riser protection net (Fig. 1),

with 4.7 in. diameter primary ropes, stretches between the TLP's four 31 m (102 ft) diameter columns that are 80 m (262 ft) apart (Fig. 2).

Hoechst Celanese Corp. manufactures the Trevira, high-tenacity polyester fiber used in the net. Hoechst says this is the second installation for this net design. The first net was installed on Shell Offshore Inc.'s Auger TLP set in 2,680 ft of water of the Gulf of Mexico. Auger's nets are 30 3 140 ft, compared to the Heidrun's larger 40 3 160 ft nets. The polyester ropes for the nets weigh 8.3 kg/m (5.6 lb/ft). The main horizontal net ropes use wire rope construction, whereas, the vertical ropes are braided. Hoechst says the combined strength and elongation properties of the Type 785 1100/192 polyester fiber will absorb the energy from vessel impacts without the need for any conventional, mechanical, or pneumatic energy absorption springs. The fiber has a very low creep and resists seawater's corrosive effects. The Trevira polyester braided jacketing covers the rope core to minimize external damage to the rope, and Hoechst Celanese has developed a special marine finish to protect the ropes from internal abrasion in seawater. The net was designed by a U.S. and U.K team from Tension Technology International Ltd. (Arbroath, Scotland) with all work done in Norway under contract with Norwegian Contractors who designed and built the hull structure. !-- caption A fiber net will safeguard the Heidrun TLP's production risers from ships or other floating objects (Fig. 1). -- !-- caption The nets stretch between the columns of the TLP (Fig. 2).-- Copyright 1995 Oil & Gas Journal. All Rights Reserved.