Pressure-varible cantrol system simplifies well testing in China

A new low-cost measuring unit simplifies well testing in Chinese oil fields. Shengli Engineering & Research Institute (SERI) developed the new unit that is easy to operate and provides a large measurement range not influenced by pressure, temperature, density, viscosity, and sand content.

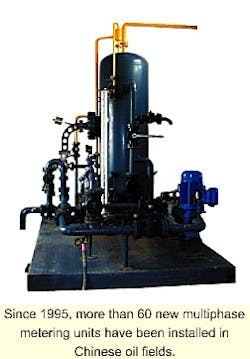

The unit consists of a two-phase separator, an oil-gas regulator, a mass flowmeter, and an intelligent spiral-vortex gas flowmeter (Fig. 1). The two-phase separator divides the well stream into liquid and gas.

The mass flowmeter measures the mass flow rate and water cut in the liquid phase, while the gas rate is obtained from the spiral-vortex flowmeter.

The metered parameters are then sent to a computer that calculates flow rates of each phase-oil, gas, and water.

More than 60 new multiphase metering units have been installed in Chinese oil fields, since completion of successful field tests in 1995.

The new units are in such locations as the:

- Chengdao offshore field of the Shengli oil complex.

- Hong-Nan, Lianmuxin, Pubei, and Shenquan blocks in the Tuha field.

- Yue-jin No. 2 and Shizigou blocks in the Qinghai field.

- Tazhong 161 block in the Tarim field.

The patented, new multiphase metering technology has passed the technical review and acceptance of the Shengli Petroleum Administrative Bureau's science and technology committee.

Well testing

These new units are replacing the traditional two-phase test separators that have a visual liquid-level monitoring glass, although two-phase separators still account for about 90% of oil well tests in China. Three-phase separators are also in use.

Two-phase separators are simple and low cost, but the production rate measured can be in error by as much as 10-20%. Also, high water cuts complicate measurement.

The three-phase test separator, on the other hand, can reduce measurement error to less than 5%; however, this technology is more complicated. It has more instrumentation and a higher maintenance cost.

Three-phase separators are more expensive to purchase and can be difficult to operate. Another problem is oil carry-over in the free-water leg that can cause additional measurement errors.

Level, pressure controls

The new unit's core technology is the oil-gas regulator that controls both separator level and pressure. The oil-gas regulator consists of a float, a connection rod, and a three-way valve.

The regulator has two, rod-connected, counter-action, directional valve cores. The regulator adjusts gas and liquid flow rates and translates the liquid level and separator pressure into an interactive relationship.

When the liquid and gas flows in and out of the separator are relatively balanced, the liquid level height and pressure stabilize. But as flow changes, the unit reacts as follows:

- Gas inflow constant, liquid rate increasing. In this case, liquid level rises and the float reduces the regulator's gas outlet and increases the oil outlet, thus reducing gas discharge and increasing the pressure and liquid discharge.

When the liquid discharge equals the liquid inflow and the gas discharge returns to its previous rate, the liquid stabilizes at a higher level and separator pressure stabilizes at a higher value.

- Gas inflow constant, liquid rate decreasing. In this case, the liquid level drops and the float increases the regulator's gas outlet and reduces the oil outlet, thus increasing gas discharge and reducing separator pressure and liquid discharge.

When the liquid discharge declines to equal the liquid inflow rate and the gas discharge returns to the original rate, the liquid stabilizes at a lower level and separator pressure stabilizes at a lower value.

- Liquid inflow constant, gas inflow increasing. In this case, rising separator pressure increases the liquid discharge and lowers the liquid level. The float increases the regulator's gas outlet and reduces the oil outlet, thus increasing gas discharge, lowering separator pressure, and reducing liquid discharge.

When the gas discharge equals the gas inflow rate and the liquid discharge returns to the original rate, the liquid stabilizes at a lower level and separator pressure returns to its original value.

- Liquid inflow constant, gas inflow decreases. In this case, declining separator pressure decreases liquid discharge, increasing the liquid level. The float reduces the regulator's gas outlet and increases the oil outlet, thus decreasing gas discharge, increasing separator pressure, and increasing liquid discharge.

When the discharged gas rate decreases to equal the incoming gas rate and the liquid discharge returns to the original rate, the liquid stabilizes at a higher level and the pressure returns to its original value.

- Large liquid volume, low gas volume inflow. In this case, the pressure immediately decreases and liquid discharge slows, so that the liquid level will quickly rise to nearly its upper-limit.

The float quickly closes the regulator's gas outlet to the minimum opening and opens the oil outlet to the maximum, so that the gas discharge slows quickly and separator pressure tends to rise.

Because the pressure cannot increase to the level required for liquid discharge in such a short time due to a very low gas rate, the liquid level immediately rises to the upper-limit position. The gas outlet is closed while the oil outlet is fully opened.

As gas discharge stops, the increased pressure accelerates the liquid discharge and its level drops. The float goes downward with the level and slightly opens the gas outlet, allowing the gas to be discharged, thus reducing separator pressure.

Because of the low gas rate, pressure continues to drop quickly until liquid discharge stops, thus causing the liquid level to rise instantaneously. This results in continuous liquid and intermittent gas discharges during the next cycle.

- Large gas volume, low liquid volume inflow. In this case, pressure immediately rises and liquid discharge quickly increases, quickly dropping the liquid level to near its lower-limit.

The float opens the regulator's gas outlet to the maximum opening and closes the oil outlet to a minimum, so that the gas discharge increases quickly and the pressure tends to drop.

Because of the low liquid rate, the liquid level cannot rise quickly and the level instantaneously decreases to its lower-limit, resulting in the oil outlet to be fully closed and the gas outlet to be fully opened.

When the liquid discharge stops, liquid level begins to rise and the float rising with the level slightly opens the oil outlet, thus causing the liquid instantaneously to discharge from the separator.

Because of the low liquid inflow, the liquid level quickly drops to its lower limit, stopping the liquid discharge from the separator. This results in a continuous gas and intermittent liquid discharge during the next cycle.

- Rising pressure at test station or flowline. In this case, liquid discharge slows, raising the liquid level. The float reduces the regulator's gas outlet and increases the oil outlet, thus reducing gas discharge, increasing separator pressure, and increasing liquid discharge.

When the liquid discharge equals the incoming liquid fluid rate and the gas discharge returns to inflow rate, the liquid stabilizes at a higher level and separator pressure stabilizes at a higher value.

- Declining pressure at the test station or flowline. In this case, liquid discharge increases, lowering the fluid level. The float increases the regulator's gas outlet and reduces the oil outlet, thus increasing gas and decreasing liquid discharge and lowering separator pressure.

When the liquid discharge equals the rate of incoming liquid and the gas discharge returns to the inflow rate, the liquid stabilizes at a lower level and the pressure stabilizes at a lower value.

The operating pressure that the regulator controls is equal to the total pressure drop required for liquid discharge and the backpressure of the flowline downstream of the regulator. The operating pressure varies with these two parameters.

Because the system is different from the conventional pressure-constant control system, it is called a "pressure-variable separator control."

Installations

In general, only one test unit is installed at a test station to measure several to more than ten producing wells in sequence. The liquid and gas streams are often fluctuant, sometimes even intermittently.

High water cut production typically experiences high liquid producing rates and low gas producing rates.

The test station backpressure is often variable and fluctuating. In this variable complicated production, the regulator automatically adjusts the liquid level and operating pressure in the separator to ensure a smooth well test operation.

Measurement instruments

In China, the tonne is the base measurement unit for oil produced. Therefore in the past, mass was derived for the parameters measured by such equipment as a positive displacement meter, water-cut analyzer, density meter, temperature gauge, etc. These parameters were then combined in a computer to obtain tonnes produced.

This process is complicated and the equipment has high manufacturing and installation costs.

The new units, on the other hand, have a liquid mass meter that measures mass flow rate, density, water cut, and temperature. The meter features a wide measurement range, no moving parts, and has no need for a filter. It, therefore, outperforms positive displacement meters and related measuring equipment.

For measuring gas, the new unit has an intelligent spiral-vortex gas flow meter. This meter has integrated temperature and pressure capabilities that output signals at both operating and standard conditions. The meter can also indicate in situ transient flow rate, accumulative gas rate, and fluid temperature and pressure.

The meter has a wide measurement range and no moving parts. It is compact and easy to operate.

Field test

For the field test, a unit (Fig. 2) was installed at the No. 21-1 metering station in the Gudong oil field, Shengli oil complex.

The metering station handles production from 13 oil wells, each having significantly different production characteristics. As an example, on June 20, 1995, the production from these wells varied as follows:

- Liquid-20-80 tonnes/day.

- Gas-98-1,854 cu m/day gas.

- Water cut-71-96%.

- GOR-1.4-32.5 cu m/tonne.

- Oil density-0.8798-0.9674 g/cc.

- Viscosity-24-4,713 mPa-s.

The unit continuously operated from Aug. 4 to Sept. 19, 1995.

During the test, the liquid level basically remained at the upper operational range. For wells with a GOR less than 0.5 cu m/tonne, the level was nearly at the upper level, while for wells with GOR less than 0.2 cu m/tonne and intermittent oil flow, the level was at the upper level while controlling the continuous liquid and intermittent gas discharges.

For wells producing high gas rates, the liquid level remained at a relatively low position.

During normal periods, the separator level fluctuated 1 to 3 cm.

The separator's operating pressure equaled the combined pressure drop required for liquid discharge out of separator and the backpressure of the flowline downstream of the regulator. At a stable export pressure, the oil wells with a large liquid volume produced at a higher working pressure.

Based on the No. 21-1 station tests, the recorded field observation showed a 0.45-0.75 MPa backpressure for flowline downstream of the regulator, a 0.02-0.1 MPa pressure drop for the liquid discharge, and a 0.47-0.8 MPa separator operating pressure.

For production conditions, the oil-gas regulator always kept a stable liquid level in the separator. The liquid level could be reliably controlled even when the stream flowing through the separator was artificially increased from 3 to 390 tonnes/day of liquid and from 40 to 6,000 cu m/day of gas.

Theoretical calculations and experience show that the oil-gas regulator has a great range for controlling liquid and gas volumes. For example, the DN50 regulator can adjust over the range of 6-400 tonnes/day of liquid and 100-30,000 cu m/day of gas.

Flowmeters

During the field test, the liquid mass meter was in continuous operation, measuring the produced liquid volume and water cut from each well. The meter can also monitor the instantaneous well stream rate and directly observe the oil well production status.

In the field test, flows from these wells ranged 16 to 160 tonnes/day. The DN50 mass meter continuously operated even when the streams were artificially reduced to 3 tonnes/day and increased to 390 tonnes/day.

The intelligent vortex gas meter, during the test, could continuously measure the gas rate from each well and display the instantaneous and accumulative flow rates locally in a backlit liquid-crystal digital display. The meter can also transmit the parameters to other locations.

The authors

Zhang Jian is a deputy-chief engineer with SERI, SINOPEC, Dongying, Shandong Province, China. His work involves the management of R&D activities. Zhang Jian has a BS in oil production from the Petroleum University of China.

Huang De-chun is a senior process engineer with SERI, SINOPEC. His work involves the research and development of process facilities used in the oil field.

Xin-an Chang is a director at the process department in SERI, SINOPEC, Dongying, Shandong Province, China. His work involves the management of R&D activities and field application.

Wang Yong is a director of engineers at the information consultation department in SERI, SINOPEC, Dongying, Shandong Province, China. His work involves the selection, introduction, and recommendation of state-of-art oil field technologies and equipment for clients in China's oil industry. He has a BA from Anhui N. University of China 1988.