Power-pulse, seismic-while-drilling technologies tested

Engineers at the Idaho National Engineering & Environmental Laboratory have begun to study the use of hydraulic power pulses through a drilling rig's mud-circulating system.

This technology, funded partly by the US Department of Energy, promises to provide an enhanced "look" ahead of the bit in seismic-while-drilling operations. In turn, this work complements studies conducted by BP, TerraTek Inc., and Lawrence Berkeley National Laboratory on the frequency dependence of seismic wave propagation in discontinuous geologic formations.

Purpose

The goal of the study is to provide accurate predictions of formation pore pressures to optimize both casing and drilling fluids programs for overpressured zones and to avoid well-control problems.

Possible economic benefits include elimination of casing strings, maintenance of optimum hole size to total depth, and reduction of nonproductive time while drilling, said engineering personnel in a presentation at the annual meeting of the Society of Petroleum Engineers (SPE) in Dallas Oct. 1-4, 2000.

Currently, no drilling system reliably provides that capability. Deeper oil and gas reservoirs with complex geologies will be the first targets for this budding technology, researchers said. Prime candidates for pore-pressure prediction include deepwater blocks in the Gulf of Mexico that contain substantial subsalt coverage.

Industry experts say a high percentage of oil and gas reserves in more than 5,000 ft of water has significant sections of salt and subsalt transition zones.

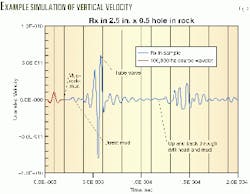

The objective for current testing is to characterize compressional wave coupling of single pressure pulses of hydraulic power into rock under a range of conditions. Pressure accelerations are measured at different distances into the rock and up the drill stem, along with average pressure and strain resulting from hydraulic pulsations through the mud-circulating system.

Setup

A drilling test rig conducted the tests using a 15.5 x 36-in. core of Mancos shale from central Utah-a cretaceous shaly siltstone with 15-20% clay content (Fig. 1). Five accelerometers were installed in the core. Other measurement instruments also included a pressure transducer placed 6 ft above the core sample and a hydrophone installed on top of the core.

To develop an experimental methodology for evaluating prototype downhole seismic sources, engineers conducted a series of six hydraulic coupling tests under differential pressures of 6,000-8,000 psi. Coupling tests were performed at 2,000-10,000 psi.

Initial results suggest that additional accelerometers will be needed in future rock samples for increased reliability and validation of the modeling (Fig. 2), said officials. Researchers hope to benchmark seismic sources in the lab before deploying the tools in expensive offshore operations.