Creating agility through supply chain automation

Tehseen Ali Dahya, Verian Technologies, Charlotte, NC

Although the exploration and production industry has never been predictable, we currently find ourselves in an unprecedented period of severe uncertainty.

Most recently, the Deepwater Horizon crisis has us bracing for an impending wave of new regulations and taxes. The unrelenting recession has continued the tightening in our industry. Crude oil and natural gas prices have also recently seen some of the wildest swings in recent history.

After a long period of stable and even modest prices, we've seen sudden increases in several categories of oil country goods. As a result, vendors unexpectedly stiffen when pressed for discounts and some have even increased prices. This is yet another surprise that wasn't on anyone's spreadsheet models for project economics.

Also without warning, we've seen critical oil field materials in short supply. Drilling projects have been stopped in their tracks and wells haven't been put back online.

We've also seen the pipeline and gathering system capacity dry up. Offline wells that returned to production saw no capacity as new wells quickly took their place.

All of this uncertainty has put pressure on relationships that were established during better times. Relationships with partners, regulators, and especially vendors grow tense when the future is uncertain. Complex relationships such as vendor-managed inventories are subject to particular strain.

Responding to uncertainty with agility

It's easy for organizations to flourish in good times. To truly thrive during upswings and downturns requires superior foresight, planning, and discipline. Years ago, consultants coined the term "corporate agility." While it seemed like jargon at the time, its true meaning is just now being understood. In times of uncertainty, one must be prepared for sudden changes in direction that cannot be anticipated. The ability to jump either way is a requirement in today's climate.

Agility gives E&P companies the unique ability to react faster and move more nimbly in an environment that changes almost hourly. So how does one go from an interesting concept to real action in the E&P industry? Where does an E&P company start if it wants to create agility?

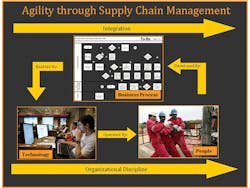

One key contributor to corporate agility is in the management of the supply chain. To become an agile company that can ramp up or scale back at a moment's notice, an agile supply chain is a necessity. For most E&P companies, having an agile supply chain translates to four basic requirements:

- Clear visibility into spending

- True contract leverage and negotiation

- Robust inventory and asset tracking

- Proactive maintenance and repair

Execution of each requirement calls for a careful balance of people, process and technology.

Agile people

Creating agility in oil field supply chains is all about working with people to affect change. Although culture change has always been difficult in the E&P world, towing the line of "this is the way we've always done it" simply won't work anymore. The industry is changing before our eyes and old rules simply do not apply anymore. The most successful E&P employees will be those that champion new solutions to old problems.

To engage and empower agility in an E&P company, employees must have involvement and buy-in to new business processes and technology right from the beginning. They must understand what agility means, how it helps make their jobs easier, and how it will make their companies more successful.

Overcoming well-established mindsets in the oil field isn't an easy task, but when people understand how agility affects them, the company and the industry, they are much more open and supportive of change that supports agility.

Agile business processes

Business processes are the most fertile area for agility in the E&P industry. Traditionally, a "cowboy" environment has created a world where everybody can buy anything and nobody can get what they need. Goods are routinely expedited at extra cost to accommodate breakdowns. Invoices must be walked around to get payment so that vendors will not hold up critical materials. All of this drives up the cost of projects and makes operations more difficult to manage.

Agile business processes allow for effective communication between field operations, management, and vendors. Control is maintained over the availability and the cost of materials. Treasury is forewarned of the need to pay for services and products. Project and operations costs can easily be accessed so that action can be taken proactively to improve results. These efficiencies are created by careful design and implementation of supply chain business processes that fit an individual E&P company's profile of drilling projects and operating wells.

Agile technology

Technology is the bridge that connects people and business processes to execute supply chain agility. Unfortunately, many oil and gas companies are using outdated technology that limits their ability to operate effectively in today's business world.

Agile business processes require automation solutions to operate. The power of technology is essential to help the E&P industry deal with the distance and complexity distinctive to our world.

Modern E&P technology solutions, including procurement and materials management automation, help achieve supply chain agility in many ways. It starts with giving you a clear view of spending and the true cost of operations. It deals with the complexity of materials and the need to look across several vendor catalogs. It extends to the ability to see materials in transit and commitments made as a part of project status.

Finally, automation technology provides information that allows the evaluation of materials, vendors and projects so that project and operational performance continues to improve.

In short, automation technology helps shorten the reaction time of E&P companies. Whether an outfit is scaling back or ramping up, automation facilitates a smooth, streamlined process rather than the lurches and jumps that have plagued our industry for decades.

It takes organizational discipline to implement supply chain agility. The trouble is most of our experience is based on trying to achieve discipline around broken processes and inadequate technology.

Oil and gas companies can use advanced automation technology to gain more control and visibility over their spending.

Real-world applications

So how does all this work out in the field? A few leading E&P companies have bought into supply chain agility and are already reaping the benefits of automation initiatives.

Freeing up capital is one of the best ways for E&P companies to become more agile. Seeing the potential savings to be gained from consolidating spending to fewer suppliers, one E&P company implemented an automation system that enabled the purchasing team to leverage the additional volume and drive lower prices.

The system reigns in "maverick spenders" by providing an online portal where employees can only order from contracted vendors. The company anticipated 4% in savings from reduced cost of goods and services through supplier rationalization and greater contract compliance. With more than $160 million in annual operation spend and a $1 billion capital budget, those savings equate to at least $6.4 million annually. That capital cushion gives the company the ability to better weather the ups and downs of the industry.

Other firms are creating an agile supply chain through greater inventory visibility from automation. One E&P company used their automated software solution to help them ship a compressor from Houston to India. Along the way, the shipment needed to be inspected and inventoried a total of three times in three different locations.

Each stop also meant currency conversions, expense allocation and detail tracking. To help monitor each leg of the journey, the automation system created "virtual warehouses" to serve as electronic mile markers. This visibility allowed them to proceed with confidence, something that rarely happens when your drilling operation is a half a world away.

Of course, agility won't come overnight. E&P companies will find that agility is more of a journey than a destination. But with the right people, processes and technology, many firms will be able to position themselves for the future by becoming more agile.

About the author

Tehseen Ali Dahya, president & CEO of Verian Technologies, has spent nearly 20 years working in the oil and gas, supply chain, wholesale distribution, healthcare GPO, and purchase-to-pay arenas. He has been a presenter at many industry events. Verian Technologies' clients in the petroleum sector include W&T Offshore, JM Huber Natural Resources, and Cobalt International Energy. Tehseen has an engineering degree from Queen's University in Canada and an MBA from the University of South Carolina.

More Oil & Gas Financial Journal Current Issue Articles

More Oil & Gas Financial Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com