Alan Armstrong, President and CEO of Williams | Interveiw

All photos by Evan Taylor.

Company will focus on areas where it has a strong competitive advantage

OIL & GAS FINANCIAL JOURNAL: Williams traces its roots back to 1908 and is one of the oldest companies doing business in the midstream sector. What does that legacy mean to you as CEO, and what are your plans for the company?

ALAN ARMSTRONG: Earlier this year, we lost John H. Williams, a second-generation founder of the company that became modern-day Williams. John was both an inspirational figure to me and a good friend. The Williams family created a company based on traditional American values and an entrepreneurial spirit. That legacy has carried on for more than a century.

Preserving and sustaining that legacy means a lot to me and to our employees. Williams is not a company that stands still for long. It has always been a company that embraces change, seeks new opportunity, and takes risks to succeed. As a major provider of energy infrastructure, Williams today is in a unique position to help our customers and our country take advantage of these tremendous unconventional resources by connecting the very best supplies to the very best markets. Our business strategy positions us to seize that opportunity in a significant way.

OGFJ: Can you tell our readers how you got started at Williams?

ARMSTRONG: I started with the company right out of school. I graduated from the University of Oklahoma in 1985 with a degree in civil engineering and joined Williams in 1986 as an engineer. On my first assignment with the company, I was sent to automate a natural gas pipeline compressor station located in the middle of Kansas, not exactly what I was expecting as a civil engineer. I learned to do what engineers do. Folks taught me to break down the big, complex project into a logical plan of small actions that accomplished the objective. I've done a lot of different things at Williams over the course of these last 27 years. I started in the gas pipeline segment, and led our midstream businesses; I've had the opportunity to spend time really understanding our customers' needs and expectations when I was in business development; and, of course, earlier in my career I was exposed to the operations side of the business. That foundation of engineering — problem-solving and breaking things down to their smallest element — has served me well during my career at Williams.

Williams has always been a great place to be, and it's provided a lot of opportunity for me and other folks. The company has never been afraid to shift its focus when it needed to, and I think that's why it's had the longevity it has.

OGFJ: How did Williams first get into the midstream business?

ARMSTRONG: Our first gas pipeline was a little pipeline system in Louisiana that connected a fertilizer plant that Williams held at the time with some natural gas reserves the company had acquired because that obviously was a major cost for a large nitrogen plant. So Williams' first entry into the space was just connecting its own supplies to its own market. But the way we really stepped into the midstream space, at least the gathering and processing part, was our acquisition of Northwest Pipeline.

We saw an opportunity to deregulate a lot of the gathering systems in the early to mid ‘80s. We were the first company to file to segregate our gathering and processing systems away from the FERC-regulated pipeline that was Northwest Pipeline at the time. From that, it blossomed as a very substantial business. Over time, Williams used that as a model for recreating businesses in many different forms. For example, more than 25 years ago, we took some of our decommissioned pipelines and converted them to serve as conduits for fiber-optics that were part of the build-out of the nation's new digital infrastructure. So we have a history of shifting our business focus to respond to the market conditions.

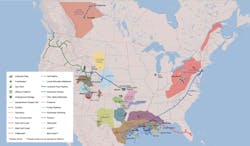

OGFJ: Williams is probably best known for its nationwide system of natural gas pipelines. Can you give our readers an overview of Williams' extensive midstream assets?

ARMSTRONG: You can think about Williams' gathering and processing assets meeting two criteria. First is "large scale." You will see Williams where the resource — the current and future production — is robust and long-lived enough to demand large-scale gathering and processing infrastructure. For us, large scale drives cost efficiency, creates more opportunities for operational excellence and serves as a magnet for market connections.

Scale is an important driver for access to high-value markets, which is the second key characteristic of Williams' gathering and processing assets. It can be a huge economic difference maker to a producer — whether their production has a ready outlet to multiple, high-demand markets or if they are penalized with production that essentially ends up in a cul de sac at a saturated market.

Access to high-value markets drives value for producers. When producers get full value for their natural gas — and, for rich gas, the liquids, too — it creates an environment that can sustain the steady development of the resource. Access to steady and relatively low-priced supply is exactly what markets need to see to fully commit to making the most of the nation's bounty of natural gas resources.

OGFJ: Are your assets mainly in North America?

ARMSTRONG: Yes. The last big group of assets we had outside of North America was in South America, and those were expropriated by the Venezuelan government. We finally settled on that last year and have been receiving cash payments from PDVSA toward a total of $312 million.

We see the international market as critical to our future success, but not in the way you typically think about it. I don't see us investing capital internationally because we have so much opportunity here in North America. But, the importance of exports — natural gas liquids, LNG, and even derivative products of natural gas and natural gas liquids like olefins and polyolefins — can't be overemphasized. We are going to have to find a way into the export markets because we have such an abundance of low-cost products here. Exports are probably more strategic to the company now than they have ever been.

OGFJ: You mentioned that you serve a dual role — president and CEO of Williams and chairman and CEO of Williams Partners LP, an MLP that owns most of your gas pipeline and domestic midstream assets. When was the MLP formed, and can you discuss the connection between the two entities?

ARMSTRONG: We formed Williams Partners LP eight years ago and have grown it into one of the largest MLPs. Today, the majority of our assets in the US are held in Williams Partners.

That ownership looks like this: Williams serves as the general partner and owns almost two-thirds of the limited-partner units. A little over one-third of the limited-partner units are publicly held and traded on the New York Stock Exchange.

For Williams, the partnership serves as a source of competitively advantaged capital to fund the significant growth projects on our plate. Like other MLPs, Williams Partners is focused on an income stream that provides predictable income that translates into a source of cash that we distribute to investors. As the partnership's largest investor, the cash that Williams receives quarterly from the partnership has been substantial and we view it as an important source of income for the cash dividends we pay to Williams investors.

OGFJ: In December 2011, Williams spun off its E&P operations as WPX Energy. Can you explain the rationale behind that?

ARMSTRONG: Sure. This was not an easy decision but both businesses had tremendous investment opportunities that were well beyond our cash flows. Our stock price was undervalued and therefore issuing equity was too expensive. As a result, we needed to segregate the businesses and the investor base and allow for more efficient funding of our tremendous capital investment portfolio. Ultimately, we believed we could create more shareholder value by spinning off E&P, resulting in two separate companies with two distinct investment profiles. To date, that belief has been realized by the combined performance of Williams and WPX Energy. The separation has allowed us to sharpen the focus on our infrastructure strategy. And we are pleased to have the opportunity to serve WPX Energy, which is one of our top customers.

OGFJ: I've heard you speak at CERA Week and know you're often invited to speak at numerous conferences as sort of spokesman for the midstream business. There's a lot of infrastructure building going on today, in large part due to the development of shale resource plays. Has all this construction re-energized this business segment and how long will this new building phase continue?

ARMSTRONG: I'm glad you asked that question. We are in the midst of a once-in-a-lifetime opportunity that is critical to our nation and our industry. But that opportunity could pass us by if we fail to act. The constraints we're seeing today and some of the concerns around land use are really starting to threaten this great renaissance that is occurring on the back of low-cost natural gas in the US because the price of building plants and pipelines based on all the permitting issues and other requirements.

Increasingly, we are facing a lack of jurisdictional certainty. Just because you get a permit for a wetlands crossing from one agency doesn't mean the other overlapping regulators will allow you to proceed. Sometimes the agencies fight with each other over who has the right to tell you how to do it. It's a mess, and it's really costing our industry a lot right now.

Here's an example. The cost per mile of our last big pipeline project in the Marcellus area is 2.4 times higher than the cost of laying a deepwater pipeline in the Gulf of Mexico. The onshore pipeline is relatively simple and runs mostly through rural areas, whereas the deepwater pipeline is in 8,000 feet of water and is much more complex in terms of engineering. The added cost of the onshore pipeline is due primarily to regulatory and land-use issues.

If we don't bring some common sense to our regulatory practices and if we don't understand the burden all these land-use constraints are putting on the industry, eventually they will choke off what is truly an incredible opportunity for our country. To seize the opportunity, it's important that everyone understands the benefits of this great resource under our feet.

We believe strongly in minimizing the damage to our environment when we build our infrastructure and can accept stringent, effective regulation, but our industry really needs to push back ineffective and mutually exclusive rules that overlapping agencies continue to impose.

OGFJ: In general, investors tend to view the midstream business as less risky than upstream. However, in the event new restrictions were enacted on hydraulic fracturing, that could seriously impact shale development. How would that impact the midstream business in the US?

ARMSTRONG: As one ponders this question they should realize that it is more than just shale gas resources that utilize hydraulic fracturing to unlock the hydrocarbons trapped in the earth. Hydraulic fracturing also has been used for decades to liberate tight sands or sandstone formations. In fact, today gas sourced from tight sands and shale makes up over 60% of total US natural gas production.

The growth of our business in the Northeast is directly related to the development of vast shale gas reserves in the Marcellus and Utica. We know hydraulic fracturing is a proven, safe, efficient method of producing unconventional gas. It's also a catalyst for tremendous economic growth in the United States — the kind of growth that hasn't been seen in decades. The producers who are our customers take very seriously the responsibility of safe and conscientious operations, just as we do. So, while we would not be shocked if new regulations are added to the local, state and federal oversight that's already in place, we do not think that prohibition at this point is feasible.

OGFJ: What do you see as some of the best opportunities for Williams?

ARMSTRONG: There are so many, but we remain focused on areas where we have a strong competitive advantage. We are in a capital allocation mode. In other words, we have more opportunities to invest today than we have capital available to invest. So we generally will be allocating capital to areas where we already have a significant competitive advantage because those areas are going to provide us the highest return.

We have worked hard over the years to high grade our assets and to develop significant competitive advantages. These competitive advantages are yielding a tremendous portfolio of investment opportunities in everything from doubling the capacity and profitability of our Transco Pipeline System by connecting new supplies to growing natural gas markets, to building critical infrastructure that connects the Marcellus and Utica NGLs to growing petchem demand in the Gulf Coast, to deepwater infrastructure and unique Canadian Oil Sands offgas infrastructure. Our challenge now is to build the infrastructure to connect these new supply areas with access to the highest-value markets.

Ultimately, there will also be opportunities in international markets as export facilities come online. In that regard, we have a vantage point on markets for NGLs, in particular, with the olefins and petchem services part of our business.

OGFJ: Let's talk a little about some of the major projects you have going on currently. Williams recently signed JV agreements with Boardwalk Pipeline Partners to build an LPG export facility at Moss Lake, near Lake Charles, LA. Can you tell us about that and when you expect it to begin operations?

ARMSTRONG: It's all about market optionality over the long term. There's an abundance of NGLs coming out of the Marcellus and Utica, but few outlets to get those products to market. So we're partnering with Boardwalk to develop the Bluegrass Pipeline, which combines a new-build section of pipeline through Ohio and Kentucky with an existing pipeline that Boardwalk is converting from natural gas to liquids. Bluegrass will provide transportation service to the Gulf Coast petchem complex or export facilities and will be well positioned to help establish petchem demand centers in the Northeast as well.

Beyond the surge in US demand, we believe there's a strong market internationally as well. So in connection with the Bluegrass project, we recently formalized a plan, again with Boardwalk, to develop an LPG export facility in Lake Charles. The proposed Moss Lake LPG Terminal would be located on the Calcasieu River and serve tanker ships transporting propane and butane to Asian, Latin American and European markets.

OGFJ: How important is the ability to export natural gas and natural gas liquids internationally to Asia, Europe, and elsewhere to the future of the natural gas industry?

ARMSTRONG: It's important for natural gas and natural gas liquids to find the best markets. The good news is that there are all kinds of indicators — and investment dollars — proving that demand exists in a variety of high-value markets. US natural gas — and NGLs — are very competitively priced vs. the global market, which should eventually open up Asia and Europe with the right infrastructure in place. The United States will still be advantaged because it will enjoy the price of natural gas before it pays tolls and shipping expenses to foreign markets.

OGFJ: What are some of the other projects being developed or being expanded?

ARMSTRONG: We're aggressively ramping up the scale of our gathering and processing operations in the Northeast. Again, our customers are looking to us to execute on our plans to create new and expanded market access. Also, in the Northeast, we're expanding our Transco pipeline to get those Marcellus and Utica volumes into New York, New Jersey and growing markets all along the eastern seaboard and southeast markets. Just this month (November 1), we put into full-service our Northeast Supply Link project, which is the first expansion on Transco that brings Marcellus gas into New York. That's just one of several Transco projects in the Northeast, but there's plenty of growth in the Southeast as well, as power generators are converting old plants to natural gas or building new ones.

The deepwater Gulf of Mexico is another major growth area. Next year, we will deploy Gulfstar FPS, which is the first offshore production spar of its kind built in America. This first one is a joint venture with Marubeni, but we certainly don't expect it to be the last. It is engineered to be a standardized, repeatable design with plug-and-play options, and producers are responding favorably to the concept.

OGFJ: Williams has extensive assets in the Gulf of Mexico. How challenging is this environment in terms of engineering and construction, especially in developing deepwater infrastructure?

ARMSTRONG: Obviously, the challenges are immense and they require sophisticated engineering and construction techniques along with very thorough planning. At Williams, we have a proven track record of successfully designing and building these types of facilities. But they don't happen overnight, which is one reason our Gulfstar FPS concept is so attractive to producers. With its standardized design, Gulfstar takes about 30 months to first oil, which is much faster than most facilities that are designed and built on a one-off basis.

OGFJ: The GoM is also noted for hurricane activity, and we've had some major storms in recent years — Katrina, Rita, Ike – just to name a few. Has Williams sustained major damage to its offshore pipelines during these storms? I've read about anchors and equipment being dragged across the sea floor and literally tearing apart pipelines. How big a problem is this to the company, and how do you deal with it?

ARMSTRONG: Of course, hurricanes are always a concern. We stay vigilant at all times, closely monitor weather patterns and take necessary steps to protect our employees, our assets and the environment. In advance of threatening weather, part of our preparation process includes securing pipelines and platforms in a controlled manner and evacuating personnel. In fact, as precautionary measures ahead of Tropical Storm Karen this year, we secured, shut down and evacuated three platforms in the eastern Gulf of Mexico. Hurricane Ivan caused significant damage back in 2004. But we've been fairly fortunate in recent years not to have experienced as much damage as some operators. Most of the debilitating damage has occurred in the shallower waters where older platforms and pipelines are susceptible to wave height and anchor drags.

Should a storm cause damage, we have a robust response plan in place to minimize impact to our operations and the environment. In 2008, around the time of Hurricane Ike, our engineers created what we call PERK, or Pipeline Emergency Repair Kit. This kit is equipped with supplies to make remote pipeline repairs at water depths of more than 8,500 feet. PERK is housed outside the danger zone in a 15,000-square-foot warehouse facility near Ragley, La. It includes a complete inventory of equipment needed for subsea pipeline repairs – even very expensive items that would normally take up to a year to acquire.

OGFJ: In June, an explosion occurred at your Geismar, La., facility. Can you talk about how the recovery is going there, as well as the planned expansion?

ARMSTRONG: June 13 was a tragic day for the entire Williams family. We lost two very valuable members of our Geismar team in that incident, and many others were injured. The magnitude of this accident is unprecedented for us.

I will also say that I was extremely proud of the way our team responded that day and has responded since that time. Our entire organization can take pride that the company's investigation, our follow-up studies, the actions we'll take to address issues and our ongoing work with federal investigators' efforts meet the standard of openness and transparency with which we conduct our business every day. It's the same uncompromising, high-integrity approach that is a hallmark of Williams' core values and benefits.

As we continue to cooperate in a transparent manner with the investigative agencies, we are working diligently to get the facility back online in April of next year. During that same time frame, we also expect to bring online an expansion to increase the plant's ethylene production capacity by approximately 50 percent.

We look forward to safely rebuilding and expanding our Geismar facility, which is an important component of our NGL and petchem services strategy.

OGFJ: Can you talk a little about Williams' financial performance? With the growth in midstream infrastructure in recent years, I would think it's an attractive opportunity for many investors.

ARMSTRONG: Investors have demonstrated a great deal of confidence in our strategy and direction as a corporation. In 2012, we undertook a reorganization that created a foundation for a more integrated, focused company. We believe that the "One Williams" mindset will benefit shareholders as we work together across organizational lines, regulated and unregulated, gas and liquids, to pursue opportunities that create long-term value.

Our cash dividends for shareholders continue to increase at an annual growth rate of 20% , and since 2010 have increased at a CAGR of 43.6%. This high-dividend growth is central to our value creation strategy. We've taken steps to ensure that even while we invest capital in building out infrastructure, we continue rewarding investors along the way. We are also investing to connect the best supply areas with the best markets, and we get paid predictable fees for these services. Since we focus on very large-scale strategic investments, a major build out period like we are experiencing is both a blessing and a challenge. It generally takes three years to convert a large-scale investment to positive free cash flow. The investments are terrific, but the near term funding takes some heavy lifting.

OGFJ: You are an active member of the Tulsa Regional Chamber and are very involved in encouraging economic development for that area. In addition, you are on the boards of Junior Achievement and the Philbrook Museum of Art. This is a lot of work in addition to your leadership role at Williams. How do you find time for it?

ARMSTRONG: I believe strongly in investing not just money, but time, in making our community a better place to live and work. For companies like Williams to grow and prosper, we need the very best talent. We're in constant competition with other cities across the country and to attract the very best talent, we need a high quality of life.

Williams always has been a strong corporate citizen everywhere we operate. Our employees volunteer with organizations all across the country. We're in the midst of wrapping up our annual United Way campaign, which is highly regarded on a national level. In fact, McGraw-Hill recently filmed some of our United Way activities as a video component of a business course textbook that will be in colleges next year. We're very proud of our employees and all they do to enhance the areas in which we operate. Our employees are the individuals who really earn Williams its reputation for supporting the community. Organizations that I work with also understand that my obligation to leading Williams comes first.

OGFJ: Thanks very much for your time.