CERI: Operational efficiencies possible in Canadian shale

Canadian unconventional oil and gas operators can improve operational efficiencies and can take measures to reduce their reliance on local fresh water, the Canadian Energy Research Institute (CERI) concluded.

Increasing strain on available resources can manifest through rising capital cost intensity due to limited labor supplies and construction materials, and environmental costs such as consumptive use of fresh water and emissions of greenhouse gases (GHG), CERI explained in its report, "Process Efficiencies of Unconventional Oil & Gas."

Primary options for improving energy efficiency include using readily available, economically viable technologies that reduce overall energy consumption. Aging facilities or slow adoption of new technologies can hinder operational efficiency, the report said. Remedies include optimizing the operations of existing equipment to replacing outdated equipment, CERI said.

Growth is anticipated in Canada's natural gas production from shale and also from oil sands, placing pressure on the construction industry and leading to inflated costs.

CERI notes shale gas resources in the Montney and Horn River basins of northeastern British Columbia involve regions having relatively little previous drilling, and services tend to reside in areas distant to the drilling locations. Construction delays due to transport or scarcity of materials can be avoided by:

• Locating rig storage and servicing equipment in municipalities closer to shale development.

• Coordinating drilling activity on a large scale to achieve savings from economies of scale.

• Developing local sales of hydraulic fracturing materials such as chemical additives and sand.

Addressing water issues

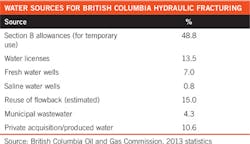

CERI said production growth exerts upward pressure on Canadian GHG emissions, and shale gas production also uses large volumes of water. In the main shale gas basins in British Columbia, low availability of surface fresh water is often an issue.

Shale gas producers can reduce reliance on local freshwater by using municipal or industrial wastewater, using fracturing additives that are compatible with lower water purity, or increasing the rate of recycling of flowback water from fractured wells. Switching from diesel rigs to those operating with natural gas can reduce energy costs and GHG emissions.

In 2013, British Columbia saw 433 wells completed with fracturing and reported an overall province average 12,300 cu m of water per well. Most of these wells were in the Montney basin, taking an average of 9,600 cu m of water per well. The Horn River basin, which has much tighter shale formations, saw only 18 wells drilled, but an average volume of 79,100 cu m of water per well.

Section 8 allowances are unlicensed water withdrawals issued at the discretion of a comptroller or regional water manager for water used on a temporary basis lasting less than 24 months. Although this water use is not formally licensed, oil and gas companies must report monthly water use under a directive from the British Columbia Oil and Gas Commission (BCOGC).

Watersheds in northeastern British Columbia have experienced several enough water shortages, that as recently as August 2014, the government suspended most of the water use from rivers, creeks, streams, and lakes with the exception of eight large rivers and two lakes, the report said.

Similar suspensions of water use were implemented in 2012 and 2010 under BCOGC directives.

"To have certainty moving forward in the development of shale gas resources in this region, ways to work within the sometimes-limited water resources in the region must be found," CERI's report noted. "One method is to store water onsite in dugouts during tiems when surface water is not limited. Typically, BCOGC directives that have limited the use of surface water is confined to lakes, streams, and rivers in a particular watershed while dugout water use is allowed," the report noted.

Another operation to increase water source and reduce environmental concerns is to reduce reliance on surface fresh water.

CERI noted Shell and the city of Dawson Creek built a wastewater treatment plant that opened in 2012. Shell uses most of the treated wastewater for its shale gas development.

"The arrangement gives Shell a reliable source of water for industrial use, gives the city of Dawson Creek a lasting piece of water treatment infrastructure, and reduces the reliance of both on fresh surface water," the report noted.